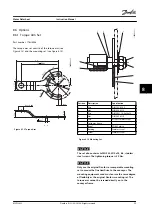

8 Motor Datasheet

8.1 Nameplate

The nameplate on the OneGearDrive is corrosion-proof. It

is made of a special plastic, approved for hazardous areas

by the Physikalisch-Technische-Bundesanstalt (PTB).

130BB851.13

INmax 7.2 A

n LT 0..212 rpm

fmax 150 Hz

tamb 40 °C

KTY 84-130

28 kg

P3

IP 69K

155 °C (F)

178uxxxxxxxxxxb011

i 14.13

Type OGDHK214K13140L06XXS31P3A9010H1BXX

Barcode

Made in Germany

M LT 0..230 Nm

3.1 L Optileb GT220

Figure 8.1 Example Nameplate

8.2 Storage

If the OneGearDrive is to be stored, ensure a dry, dust free,

and well-ventilated environment with a low vibration

rating of v

eff

<0.2 mm/s. If the temperature in the storage

space exceeds the normal range of -4

°

F to 104

°

F [-20

°

C

to 40

°

C] for an extended period or varies frequently,

employ the measures before start-up specified in

chapter 5.1 Measures before Commissioning

, even after short

storage times.

Damage sustained during storage:

•

The life of the oils and seals is reduced with

longer storage times.

•

There is a risk of fracture at low temperatures

(under approximately -4

°

F [–20

°

C]).

•

If the transport eyebolts are replaced, use drop

forged eyebolts as specified in DIN 580.

If the OneGearDrive is being stored for an extended time

before start-up, increased protection against damage by

corrosion or humidity can be achieved by observing the

following information. The actual load depends strongly on

local conditions, therefore the time period stated is only a

guide value. This period does not include any extension of

the warranty. If disassembly is necessary before start-up,

contact Danfoss Service. The instructions contained in this

instruction manual must be observed.

8.2.1 Measures during Storage

Turn the OneGearDrive 180

°

every 12 months so that the

oil in the gear unit covers the bearings and gearwheels

that were previously positioned on top. Also, turn the

output shaft manually to churn the rolling-contact bearing

grease and distribute it evenly.

The OneGearDrive does not need to be turned if it is

completely filled with oil as the result of a special

agreement. In this case, reduce the oil level before start-up

to the desired value, as defined in

and on the nameplate.

8.2.2 Measures after Storage

Repair any damage to the exterior paint layer or to the

rust protection of the bright metal shafts, including hollow

shafts.

Check that the OneGearDrive contains the correct amount

of oil and that the oil quality has not diminished during

storage. If so, follow the instructions in

chapter 6.4.4 Changing the Oil

.

8.3 Permanent Magnet 3-phase

Synchronous Motor

Rated torque

12.6 Nm

Rated current

7.2 A

Rated speed

3000 RPM

Rated frequency

250 Hz

Motor circuit

Y

Stator resistance (Rs)

0.5

Ω

Inductivity – D axis (Ld)

5 mH

Inductivity – Q axis (Lq)

5 mH

Motor poles (2p)

10

Moment of inertia

0.0043 Kgm

²

Back EMF constant (ke)

120 V/1000 RPM

Torque constant (kt)

1.75 Nm/A

Table 8.1 Specifications

Motor Datasheet

Instruction Manual

24

Danfoss A/S © 08/2014 All rights reserved.

MG75C422

8

8