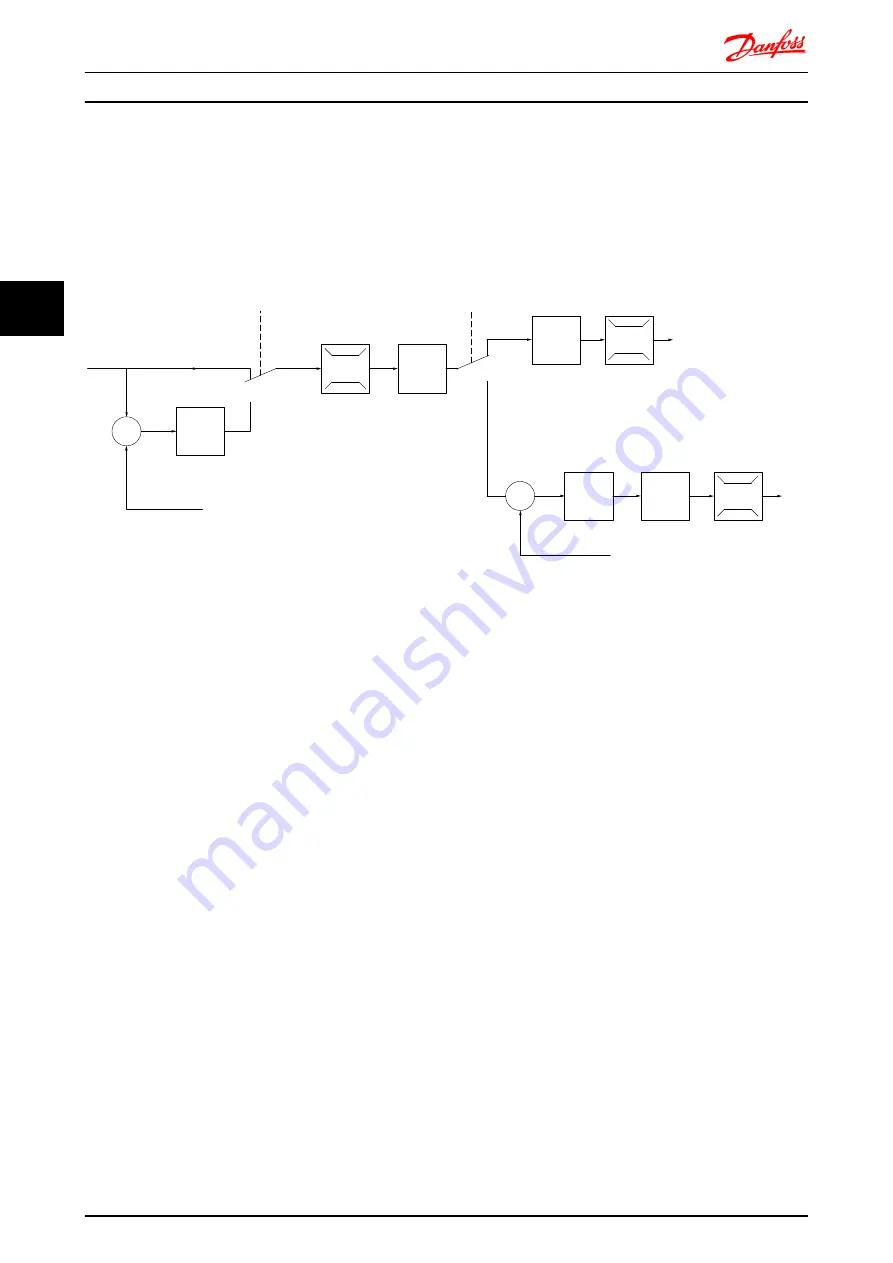

4.5 Control Structures

4.5.1 Control Structure in VVC

plus

Advanced Vector Control

+

_

+

_

Config. mode

Ref.

Process

P 1-00

High

+f max.

Low

-f max.

P 4-11

Motor speed

low limit (RPM)

P 4-12

Motor speed

low limit (Hz)

P 4-13

Motor speed

high limit (RPM)

P 4-14

Motor speed

high limit (Hz)

Motor

controller

Ramp

Speed

PID

P 7-20 Process feedback

1 source

P 7-22 Process feedback

2 source

P 7-00 Speed PID

feedback source

P 1-00

Config. mode

P 4-19

Max. output freq.

-f max.

Motor

controller

P 4-19

Max. output freq.

+f max.

P 3-**

P 7-0*

130BA055.10

Illustration 4.15 Control Structure in VVC

plus

Open Loop and Closed Loop Configurations

In the configuration shown in

,

1-01 Motor

Control Principle

is set to

[1] VVC

plus

and

1-00 Configuration

Mode

is set to

[0] Speed open loop

. The resulting reference

from the reference handling system is received and fed

through the ramp limitation and speed limitation before

being sent to the motor control. The output of the motor

control is then limited by the maximum frequency limit.

If

1-00 Configuration Mode

is set to

[1] Speed closed loop

the resulting reference passes from the ramp limitation

and speed limitation into a speed PID control. The Speed

PID control parameters are located in the parameter group

7-0*. The resulting reference from the Speed PID control is

sent to the motor control limited by the frequency limit.

Select

[3] Process

in

1-00 Configuration Mode

to use the

process PID control for closed loop control of for example,

speed or pressure in the controlled application. The

Process PID parameters are located in parameter group

7-2* and 7-3*.

4.5.2 Control Structure in Flux Sensorless

Control structure in Flux sensorless open loop and closed

loop configurations.

Application Examples

VLT

®

Decentral Drive FCD 302

62

MG04H102 - VLT

®

is a registered Danfoss trademark

4

4