All control terminals and relay terminals 01-03/04-06

comply with PELV (Protective Extra Low Voltage), with the

exception of grounded Delta leg above 400 V.

Galvanic (ensured) isolation is obtained by fulfilling

requirements for higher isolation and by providing the

relevant creepage/clearance distances. These requirements

are described in the EN 61800-5-1 standard.

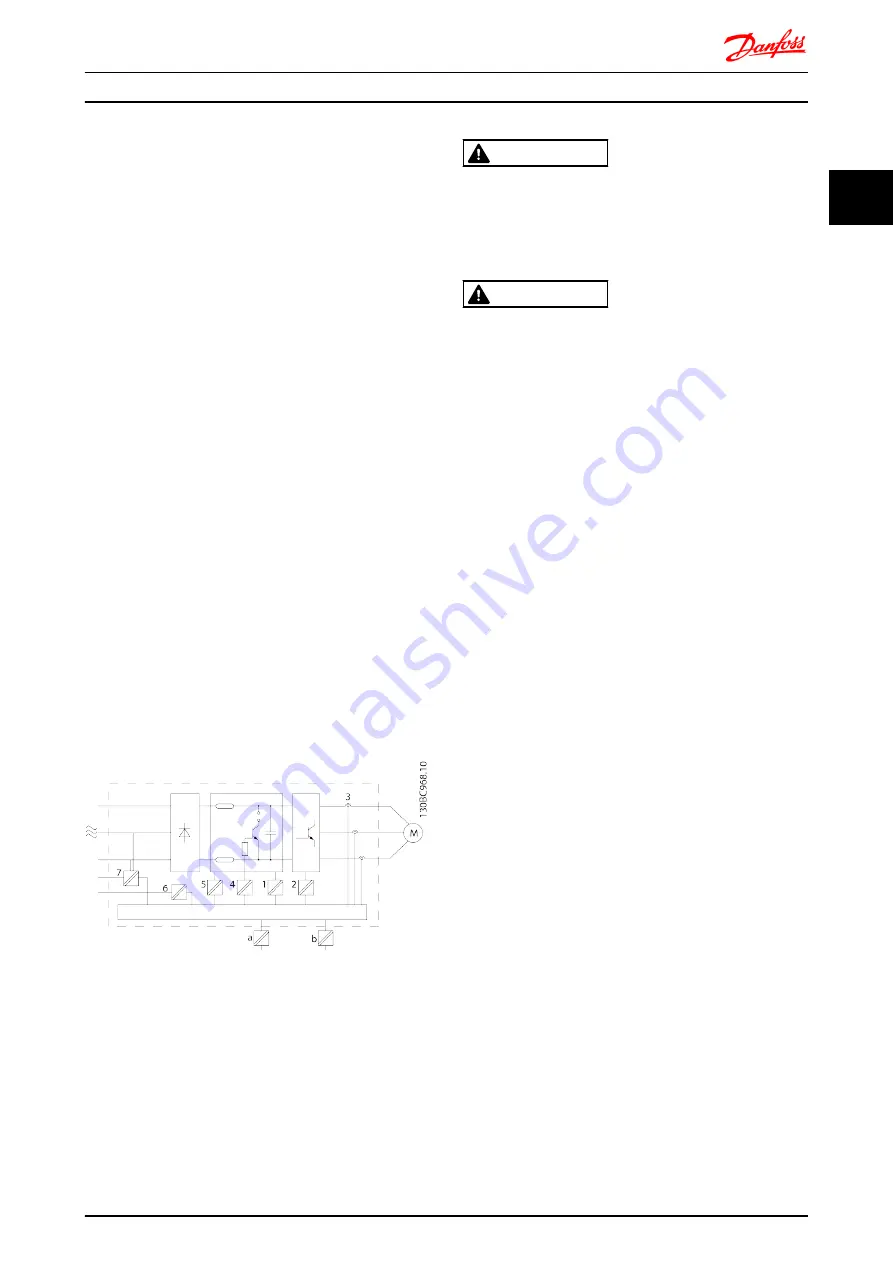

The components that make up the electrical isolation, as

described below, also comply with the requirements for

higher isolation and the relevant test as described in EN

61800-5-1.

The PELV galvanic isolation can be shown in six locations

(see

):

In order to maintain PELV all connections made to the

control terminals must be PELV, e.g. thermistor must be

reinforced/double insulated.

1.

Power supply (SMPS) incl. signal isolation of U

DC

,

indicating the voltage of intermediate DC Link

circuit.

2.

Gate drive that runs the IGBTs (trigger

transformers/opto-couplers).

3.

Current transducers.

4.

Opto-coupler, brake module.

5.

Internal inrush, RFI, and temperature

measurement circuits.

6.

Custom relays.

7.

Mechanical brake.

Illustration 2.24 Galvanic Isolation

The functional galvanic isolation (a and b on drawing) is

for the 24 V back-up option and for the RS-485 standard

bus interface.

WARNING

Installation at high altitude:

380-500 V: At altitudes above 2 km, contact Danfoss

regarding PELV.

380-500 V: At altitudes above 3 km, contact Danfoss

regarding PELV.

WARNING

Touching the electrical parts could be fatal - even after the

equipment has been disconnected from mains.

Also make sure that other voltage inputs have been

disconnected, such as load sharing (linkage of DC

intermediate circuit), as well as the motor connection for

kinetic back-up.

Before touching any electrical parts, wait at least the

amount of time indicated in

Introduction, in FCD 302,

Operating Instructions, MG04F

.

Shorter time is allowed only if indicated on the nameplate

for the specific unit.

2.6 Mechanical Brake

2.6.1 Hoist Mechanical Brake

For an example of advanced mechanical brake control for

hoisting applications, see

.

2.6.2 Brake Resistor Cabling

EMC (twisted cables/shielding)

To reduce the electrical noise from the wires between the

brake resistor and the frequency converter, the wires must

be twisted.

For enhanced EMC performance, use a metal screen.

2.7 Brake Functions

Braking function is applied for braking the load on the

motor shaft, either as dynamic braking or static braking.

2.7.1 Mechanical Holding Brake

A mechanical holding brake mounted directly on the

motor shaft normally performs static braking. In some

applications the static holding torque is working as static

holding of the motor shaft (usually synchronous

permanent motors). A holding brake is either controlled by

a PLC or directly by a digital output from the frequency

converter (relay or solid state).

Product Overview

VLT

®

Decentral Drive FCD 302

MG04H102 - VLT

®

is a registered Danfoss trademark

25

2

2