52 | © Danfoss | August 2018

AQ00000211

ENGINEERING TOMORROW

sensors are absent, then the FDA can be disabled, to avoid PVED-CLS from going into safe state (refer chapter

, for

details on FDA). Furthermore, if the system is an OSPE/EHi-E or EHi-H system, the Cut-off valve must also be connected

as a boot-up check is done on the Cut-off Valve presence.

Note: The system requires an MMI installed for changing programs, steering devices and steering modes etc.

For further information regarding sub-system requirements, please see the Danfoss document, PVED-CLS Safety Manual.

For further information regarding protocol requirements, please see the Danfoss document, PVED-CLS Communication

protocol.

8.1

WHEEL ANGLE SENSOR

The PVED-CLS can interface with

either

single/dual channel analogue wheel angle sensor

or

dual channel CAN based

wheel angle sensor, but can also be configured to no wheel angle sensor present.

Wheel angle sensor can be configured by parameters WAS interface (P3244) and Redundant WAS present (P3245).

The wheel angle sensor allows the PVED-CLS to perform closed loop position control on the steered wheels of the

vehicle, auto-guidance steering, anti-drift function as well as soft end stop features.

Important

Recommended WAS specification:

WAS on CAN = 1000 counts full scale from full left to full right. Noise less than 3% full scale

WAS analogue = Minimum 3V bandwidth full left to full right. Noise less than 3% full scale.

8.1.1

No Wheel angle sensor

If no wheel angle present in the system, parameter P3244 i.e.

WAS interface

shall be set to NONE. In this case, PVED-

CLS cannot perform closed loop control of the steered wheels, so auto-guidance or closed loop AUX joystick is not

possible. In addition, anti-drift and soft end-stop is impossible. When wheel angle sensor is disabled, the following

parameters must be set according to Table 22.

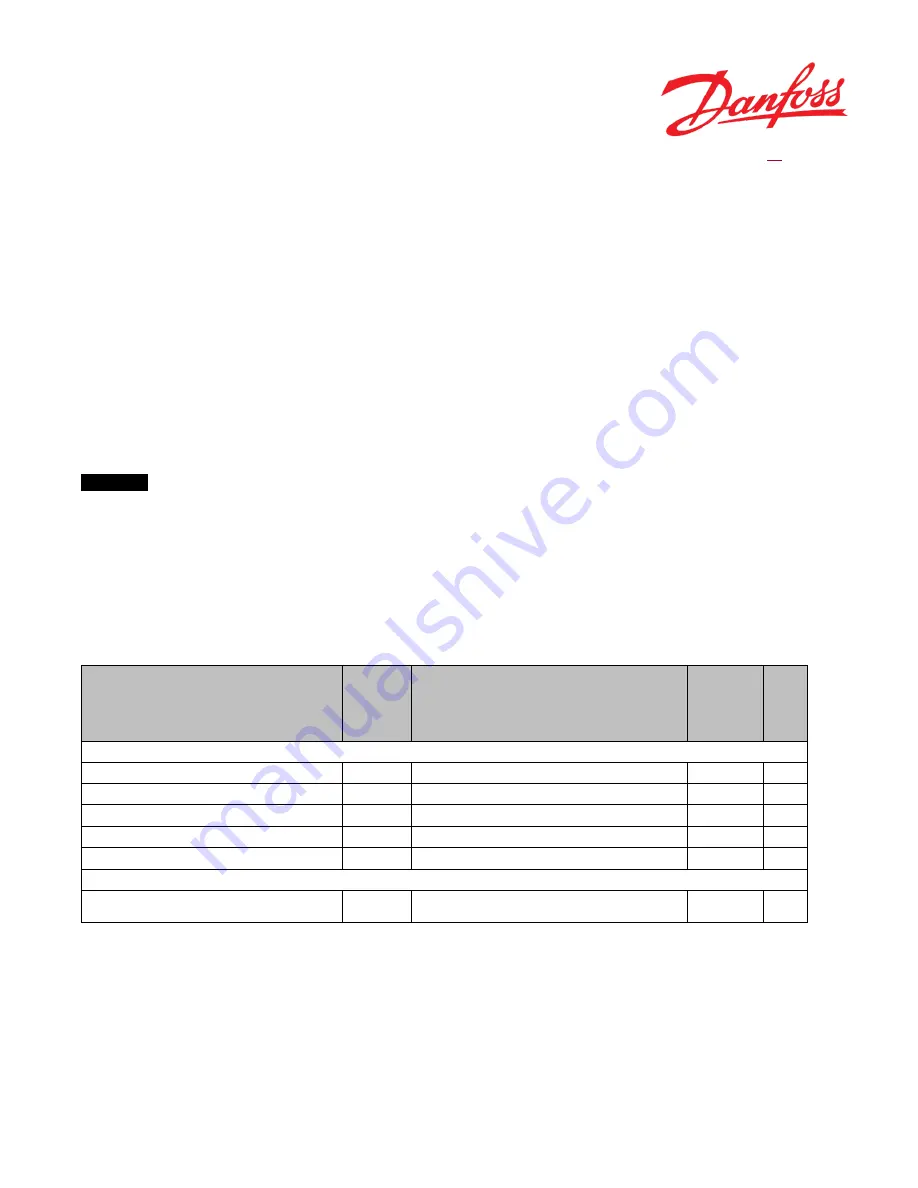

Parameter Name

Address

Description of parameter

Expected

Value

Unit

When WAS interface (P3244) == NONE

STW anti-drift - Max flow correction in percentage of full flow

P3569

Max flow correction which can be requested by the EFU algorithm

0

%

AUX anti-drift - Max flow correction in percentages of full flow

P3705

Max flow correction which can be requested by the EFU algorithm

0

%

Valve type

P3081

Valve type on which the PVED-CLS is mounted

Valid Values: 0 (OSPE, EHi); 1 (EHPS)

0

-

GPS present

P3237

GPS Present/Not Present

Valid Values: 0 (NOT PRESENT); 255 (PRESENT)

0

-

GPS2 present

P3238

GPS2 Present/Not Present

Valid Values: 0 (NOT PRESENT); 255 (PRESENT)

0

-

If AUX present (P3239) == TRUE, then

AUX type

P3240

Aux device is mini steering wheel or Joystick

Valid Values: 0 (Open Loop Joystick); 1 (Closed Loop Joystick); 2

(mini steering wheel); 3 (Analogue Joystick);20 (Elobau joystick)

≠1

-

Table 22

If these rules are not followed, PVED-CLS will enter safe state.

8.2

SPEED SENSOR

Many of the PVED-CLS’s safety functions are relying on a safe and trustworthy vehicle speed signal. The PVED-CLS is

performing crosschecks on the vehicle speed signal, therefore it is also required to send (on the CAN bus) two independent

vehicle speed signals (e.g. from two sensor sub-systems).

Summary of Contents for PVED-CLS

Page 6: ...6 Danfoss August 2018 AQ00000211 ENGINEERING TOMORROW ...

Page 71: ... Danfoss August 2018 AQ00000211 71 ENGINEERING TOMORROW Figure 29 ...

Page 127: ... Danfoss August 2018 AQ00000211 127 ENGINEERING TOMORROW ...

Page 147: ... Danfoss August 2018 AQ00000211 147 ENGINEERING TOMORROW ...

Page 182: ...182 Danfoss August 2018 AQ00000211 ENGINEERING TOMORROW ...