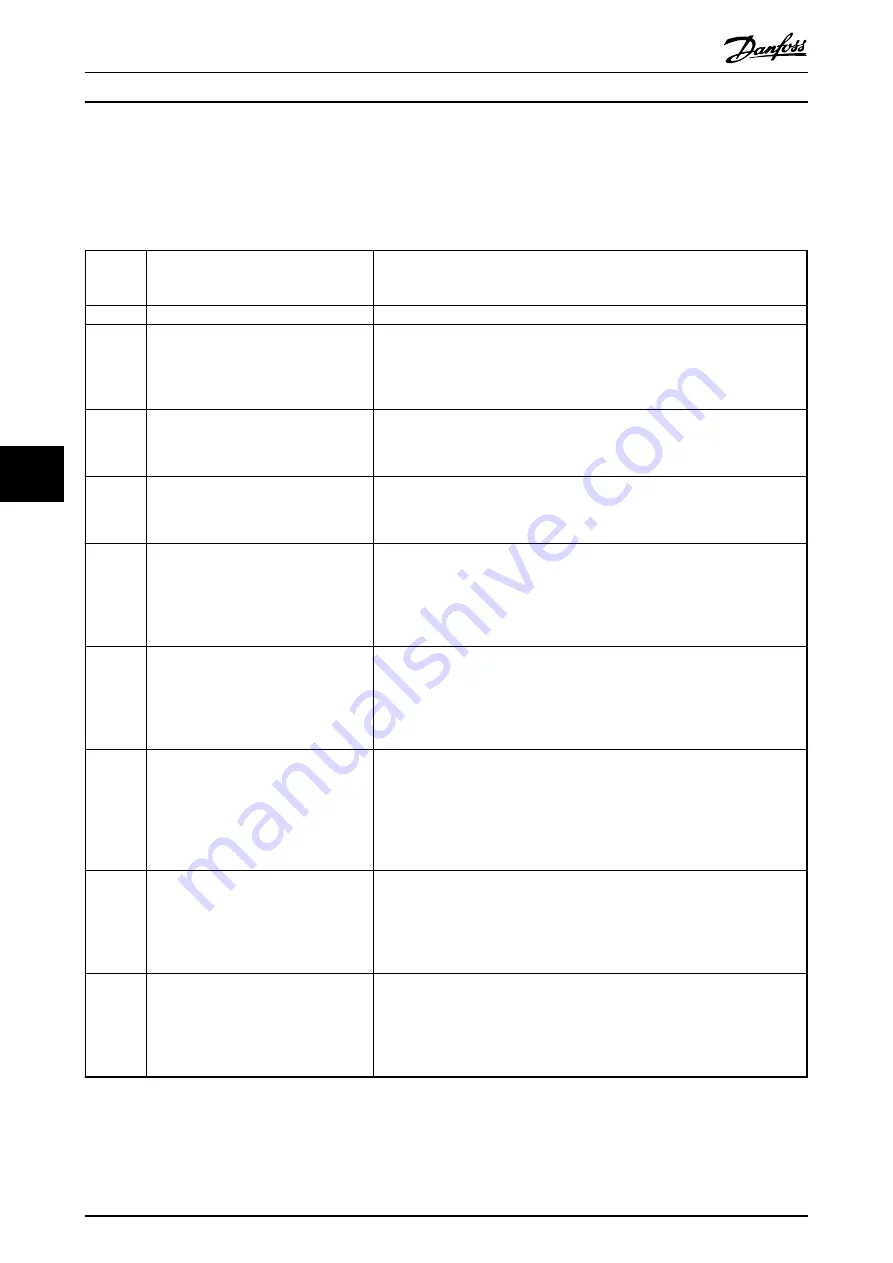

7.2 Error Messages

The LCP shows all error messages on the status screen (below the index number). They are also shown in parameter

19-93

Error Status

. Detailed information, additional notes on possible causes of errors, and tips for clearing errors can be found in

Parameter

19-93,

value

Status/error message

Meaning/cause

0

Status OK. No errors detected

No errors detected.

1

Homing needed

•

A positioning command to a certain position has been issued while the home

position is not defined.

•

Clear the error and complete a homing sequence successfully before issuing

the next position command to the application.

2

Positive hardware limit exceeded

•

The positive hardware switch input has been activated.

•

The application has hit the positive limit marker switch. Alternatively, the

connection to the limit switch has been lost or the limit switch is defective.

3

Negative hardware limit exceeded

•

The negative hardware switch input has been activated.

•

The application has hit the negative limit marker switch. Alternatively, the

connection to the limit switch has been lost or the limit switch is defective.

4

Positive software limit exceeded

•

A motor command has caused the software limit switch to be activated. The

maximum limit is specified in parameter

33-42 Positive Software End Limit

.

•

Move the application back from the limit before clearing the error. If power

recovery is enabled in parameter

19-08 Power-Recovery

, this can be done

through an error reset and a negative jog (input 54).

5

Negative software limit exceeded

•

A motor command has caused the software limit switch to be activated. The

maximum limit is specified in parameter

33-41 Negative Software End Limit

.

•

Move the application back from the limit before clearing the error. If power

recovery is enabled in parameter

19-08 Power-Recovery

, this can be done

through an error reset and a positive jog (input 53).

6

VLT not running

•

The motor was not magnetised in a situation where it should have been. The

electromechanical brake is immediately activated in this case regardless of the

settings in parameters

19-12 Hold Delay

and

19-06 Error Behaviour

.

•

While the motor was holding/driving the load, the frequency converter either

tripped, connection to terminal X57/8 was lost, or the

Hand On

or

Off

key on

the LCP was pressed.

7

Brake wear limit exceeded

•

This error message is given if the motor has moved more than the allowed

number of user units specified in parameter

19-13 Brake Wear Limit

while

the

electronic brake was activated.

•

The mechanical brake is worn and must be replaced in the near future or the

limit specified in parameter

19-13 Brake Wear Limit

is too low.

8

Quick stop input activated

•

The quick stop input has been activated. As a safety precaution, the electro-

mechanical brake is activated according to the setting in parameter

19-06 Error

Behaviour

and the motor is coasted regardless of the setting in parameter

19-09 Automatic Brake Control

.

•

Clear the error to resume normal operation.

Diagnostics

Operating Instructions

46

Danfoss A/S © 04/2014 All rights reserved.

MG33R302

7

7