Installation Guide

CONFIDENTIAL

TG-0057_19 TM4 SUMO HD CO300-A1_A2_A2.5 Installation Guide

© Dana TM4 inc., 2013-2020

Page 23 of 42

2020-11-20

4.5.3 Example installation sequence

The system integrator will define the final electrical connection sequences of the MCU and motor taking the

complete installation into consideration; the sequence for installing the MCU in Section 4.5.3.1 is given as

an example.

4.5.3.1 Suggested installation sequence

Several cables and harnesses are required for the MCU electrical connection. The following steps

summarize the electrical connection sequence of the MCU.

IMPORTANT NOTE

: Disable the high-voltage and auxiliary batteries before handling the product, or

connecting/disconnecting any cable, harness or tube.

1

Connect the grounding straps, see Section 4.5.4.

2

Connect the phase cables, see Section 4.5.5.

3

Connect the motor sensor interface harness, see Section 4.5.6.

4

Connect the VMU interface harness, see Section 4.5.7.

5

Connect the high-voltage battery cables, see Section 4.5.8.

6

Connect the auxiliary battery cables, see Section 4.5.9.

7

Connect the cooling inlet/outlet hoses, see Section 4.4.

As specified earlier, the final installation sequence should be defined by the integrator according to the

application type. However, for user safety, the grounding strap should always be installed first, and the

product should no longer be handled when the power source is enabled.

Note

: Reverse sequencing is performed when removing the system from the vehicle; remove the grounding

strap last.

4.5.4 Grounding the system

The system must be securely grounded to ensure user safety in case of an insulation fault in the motor

and/or the MCU. An incorrectly grounded connection may result in MCU functionality losses and safety

risks for the user.

IMPORTANT NOTE

: Disable the high-voltage and auxiliary batteries before connecting or disconnecting

the ground.

4.5.4.1 Grounding strap recommendations – MCU

The integrator must consider the possibility of an insulation fault where the high-voltage battery current

would find a path through the grounding strap. The grounding strap or wire must be sized to support the

maximum current of the high-voltage battery for a sufficient time for the high-voltage battery fuse to open.

Refer to Section 4.5.8.2 for the high-voltage battery fuse specification.

4.5.4.2 Connecting the grounding strap – MCU

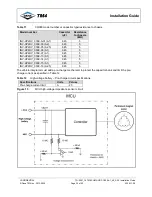

The grounding strap must be connected to its dedicated connection point (Figure 7) or to one of the

mounting points shown in Figure 3. The type of MCU grounding configuration used may vary according to

the type of vehicle integration.

Note

: To prevent oxidation of the aluminum surfaces and any malfunction of the connection during

operation, we recommend that you sand the contact point on the MCU and apply a layer of conductive

grease on the grounding strap contact surfaces before connecting the strap. The grounding strap wire

length from the MCU grounding point to the vehicle chassis should be as short as possible.