4/29/03

Model Trademaster

Section I -

11

to the degree needed and the miter gauge to the angle needed. When cutting angles or

compound miters, always slow the table feed down.

Notes: When bundle cutting always secure pieces together to prevent parts moving

during the cutting process.

When contour cutting always lock table, and use the narrowest blade possible for the

application, to prevent undo stress to the blade.

Blade tracking and guide adjustments

When a new blade is installed blade tracking may be necessary. The blade should run

as close to center of the band wheel as possible, if the blade is not centered the blade

must be tracked in.

1. Tension blade to manufactures recommendations. (It is better to be over tight than

not tight enough).

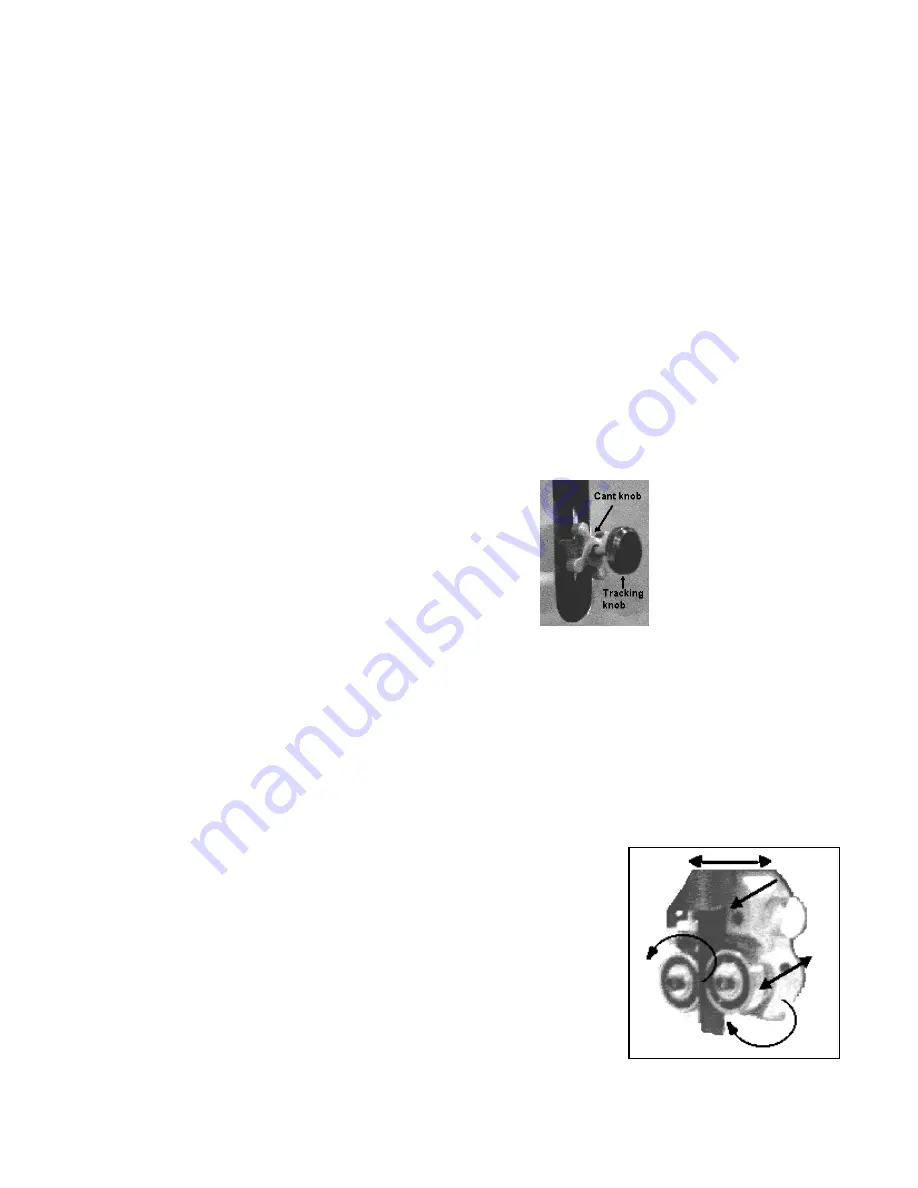

2. On the rear of the machine behind the upper wheel loosen the cant knob.

3. Adjust the center-tracking knob in or out to track the blade. Note: Make only half

turns at a time, and jog the machine as you go to check tracking.

4. After tracking is completed tighten cant knob.

Blade guide adjustment should be done from time

To time to insure the blade is being properly supported.

The guides are adjustable in five different ways.

1. The roller adjustment to loosen from the blade.

2. The roller adjustment to tighten against the blade.

3. The roller adjustment in and out for blade widths.

4. The top roller in / out side to side for support of the blades back, for centering blade

groove.

The blade must run straight through the guides without any twist or misalignment from

the upper to the lower guides. The top roller has a shallow groove in it and the

back edge of the blade is to run through this groove. The roller can be moved left or

right by loosening the setscrew and shifting the roller. The top and bottom must be in

line with each other. The back of the blade should just touch this roller. If it does not or

is too close where it bows the blade outward it must be adjusted. By loosening the

setscrew, the knurled knob can be turned to make this adjustment.

The lower rollers can be adjusted to put pressure on the blade

sides. This is done by loosening the setscrews and rotating the

eccentric axle. There should be approx. .004 of gap between

these rollers and the blade.

If you change the blade width the lower rollers (both on upper

and lower guide sets) must be adjusted accordingly. By

loosening the setscrews move the rollers so they are just

behind the blades teeth gullets. The roller must not contact the

set of the teeth.

Note: Keep the guides clean and free from chips.