SINGLE SCREW CHILLERS IMM

Engineered for Flexibility and Performance

47

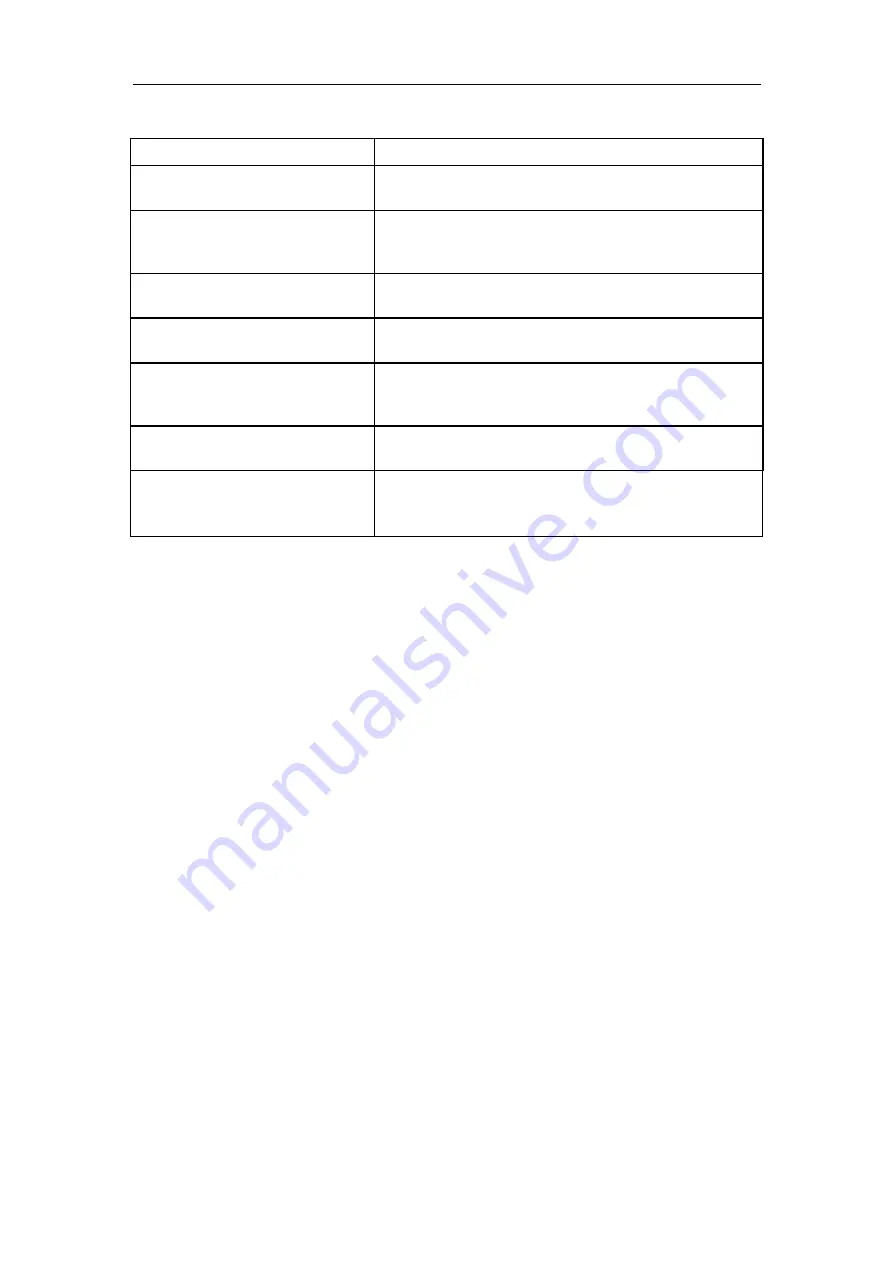

7. Fault Elimination

Phenomena or Problems

Solutions

The bellows is damaged and the

liquid leaks into the casing.

Replacement

Scraps

have

stuck

the

mechanical parts of switches

tightly.

Clear the scraps in the mechanical parts and test for

several times to ensure its normal operation.

Reverse the motion of control

switches

Check the wiring connection based on the wiring

diagram

The control switch fails to actuate

Check the wiring and check whether the flowing

direction sheet has contacted with the pipeline

The switch actuates when liquid

flows and does not reset without

liquid flow.

The direction of liquid flow shall be in line with the

direction of arrow and the liquid shall flow upward in

the vertical pipeline

The switch fails to actuate when

the flow increases

Check whether there are cracks or fractures, if any,

replace the sheet.

HMI shows phase alarm

Verify line voltage within 90% -110% of rated voltage.

Then, phase sequence protection alarm can be reset

by manually rebooting the cabinet.