15 Electrical installation

Installation and operation manual

27

RK RKXYQ8T7Y1B

VRV IV compressor unit for indoor installation

4P499900-1A – 2020.10

b

Contains fluorinated greenhouse gases

2

1

1

1

2

2

kg

tCO

2

eq

GWP × kg

1000

=

=

+

kg

=

kg

=

GWP: XXX

RXXX

a

f

c

d

e

a

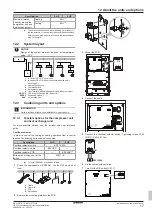

If a multilingual fluorinated greenhouse gases label is

delivered with the unit (see accessories), peel off the

applicable language and stick it on top of

a

.

b

Factory refrigerant charge: see unit name plate

c

Additional refrigerant amount charged

d

Total refrigerant charge

e

Quantity of fluorinated greenhouse gases

of the total

refrigerant charge expressed as tonnes CO

2

equivalent.

f

GWP = Global warming potential

NOTICE

Applicable legislation on

fluorinated greenhouse gases

requires that the refrigerant charge of the unit is indicated

both in weight and CO

2

equivalent.

Formula to calculate the quantity in CO

2

equivalent

tonnes:

GWP value of the refrigerant × total refrigerant

charge [in kg] / 1000

Use the GWP value mentioned on the refrigerant charge

label.

2

Fix the label on the inside of the compressor unit. There is a

dedicated place for it on the wiring diagram label.

15

Electrical installation

DANGER: RISK OF ELECTROCUTION

WARNING

ALWAYS use multicore cable for power supply cables.

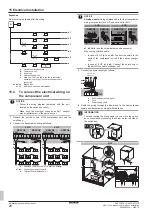

15.1

About electrical compliance

Only for RKXYQ8

This equipment complies with:

▪

EN/IEC 61000‑3‑12

provided that the short-circuit power S

sc

is

greater than or equal to the minimum S

sc

value at the interface

point between the user's supply and the public system.

▪ EN/IEC

61000‑3‑12

=

European/International

Technical

Standard setting the limits for harmonic currents produced by

equipment connected to public low-voltage systems with input

current >16 A and ≤75 A per phase.

▪ It is the responsibility of the installer or user of the equipment to

ensure, by consultation with the distribution network operator if

necessary, that the equipment is connected only to a supply

with a short-circuit power S

sc

greater than or equal to the

minimum S

sc

value.

Model

Minimum S

sc

value

RKXYQ8

3329 kVA

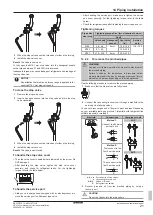

15.2

Safety device requirements

NOTICE

When using residual current operated circuit breakers, be

sure to use a high-speed type 300 mA rated residual

operating current.

Power supply: Compressor unit

The power supply must be protected with the required safety

devices, i.e. a main switch, a slow blow fuse on each phase and an

earth leakage protector in accordance with the applicable legislation.

Selection and sizing of the wiring should be done in accordance with

the applicable legislation based on the information mentioned in the

table below.

Model

Minimum circuit

ampacity

Recommended

fuses

RKXYQ5

13.5 A

16 A

RKXYQ8

17.4 A

20 A

▪ Phase and frequency: 3N~ 50 Hz

▪ Voltage: 380-415 V

Transmission wiring

Transmission line section:

Transmission wiring

Sh shielded cable (2

wires)

Vinyl cords

0.75~1.25 mm²

(using shielded cable for the

transmission wiring is mandatory

for 5 HP, and optional for 8 HP)

Maximum wiring length

(= distance between compressor

unit and furthest indoor unit)

300 m

Total wiring length

(= distance between compressor

unit and all indoor units, and

between compressor unit and

heat exchanger unit)

600 m

If the total transmission wiring exceeds these limits, it may

result in communication error.

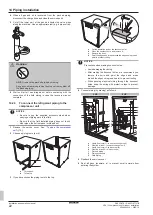

15.3

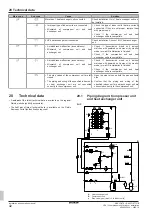

Field wiring: Overview

Field wiring consists of:

▪ Power supply (always including earth)

▪ Communication (= transmission) wiring between the compressor

unit, the heat exchanger unit, and the indoor units.

Example:

g

f

F1/F2

(16 V)

F1/F2

(16 V)

220-240 V

1~ 50 Hz

e

c

a

d

b

220-240 V

1~ 50 Hz

380-415 V

3N~ 50 Hz

a

Main switch

b

Earth connection

c

Power supply wiring (including earth) (sheathed cable)

F1/F2

Transmission wiring (sh shielded cable) (using

shielded cable for the transmission wiring is mandatory for

5 HP, and optional for 8 HP)

d

Compressor unit

e

Heat exchanger unit

f

Indoor unit

g

User interface