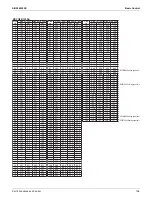

Basic Control

SiUS342303E

103

Part 4 Functions and Control

5. Basic Control

5.1 Normal

Control

Part name

Electric symbol

Function

Normal cooling

Normal heating

Compressor motor

M1C, M2C

PI control, High pressure protection, Low

pressure protection, Td protection,

Inverter protection

PI control, High pressure protection, Low

pressure protection, Td protection,

Inverter protection

Fan motor

M1F, M2F

Cooling fan control

Maximum step

Electronic expansion valve

(Heat exchanger main)

Y1E

Subcooling degree control

Superheating degree control (Subcooling

degree control in low load)

Electronic expansion valve

(Heat exchanger left)

Y6E

Subcooling degree control (0 pulse in

low load)

Superheating degree control (0 pulse in

low load)

Electronic expansion valve

(Refrigerant cooling IPM)

Y2E

Cooling refrigerant control

Cooling refrigerant control

Electronic expansion valve

(Subcooling heat exchanger)

Y3E

Superheating degree control (discharge

pipe protection)

Superheating degree control (discharge

pipe protection)

Electronic expansion valve

(Refrigerant auto charge)

Y4E

Minimum pulse

Minimum pulse

Electronic expansion valve

(Refrigerant cooling air)

Y5E

Cooling refrigerant control

Cooling refrigerant control

Solenoid valve

(Oil separator oil return)

Y1S, Y2S

ON

ON

Solenoid valve

(Hot gas bypass)

Y3S

ON

OFF

Solenoid valve

(Accumulator oil return)

Y4S

ON

ON

Solenoid valve

(Four way valve)

Y5S

OFF

ON

Solenoid valve (Injection)

Y6S

Compressor injection control

Compressor injection control

Summary of Contents for VRV EMERION RXYQ-AATJA

Page 1: ...Service Manual Heat Pump 60 Hz RXYQ AATJA 208 230 V RXYQ AAYDA 460 V SiUS342303E...

Page 410: ...Wiring Diagrams SiUS342303E 403 Part 7 Appendix FXEQ07 09 12 15 18 24PVJU 3D098557A...

Page 411: ...SiUS342303E Wiring Diagrams Part 7 Appendix 404 FXDQ07 09 12 18 24MVJU C 3D050501C...

Page 416: ...Wiring Diagrams SiUS342303E 409 Part 7 Appendix FXHQ12 24 36MVJU 3D048116C...

Page 417: ...SiUS342303E Wiring Diagrams Part 7 Appendix 410 FXAQ07 09 12 18 24PVJU 3D075354F...

Page 424: ...Wiring Diagrams SiUS342303E 417 Part 7 Appendix VAM1200GVJU 3D073270D...