IM 1287-4 • REBEL APPLIED ROOFTOP 126 www.DaikinApplied.com

Unit Maintenance

Unit Location and Clearances

While the cabinet location is normally selected by the architect,

builder, or installer, before installation ensure that the following

requirements are met before final installation:

1. Do not install unit where it may exposed to potentially

explosive or flammable vapors.

2. Do not locate unit in areas where corrosive vapors (such

as chlorinated, halogenated, or acidic) are present in

the atmosphere or can be mixed with combustion air

entering furnace.

3. Cabinet location must provide access to all doors and

panels and allow adjustment and service of the furnace.

4. Cabinet location must provide an adequate, unimpeded

supply of fresh air for combustion.

5. Flue discharge should be at least 120 inches away

from any opening or other equipment through which

combustion products could enter the building

6. Clearance from combustibles to be no less than as listed

below:

a. Furnace access side ....................... 18 in (914 mm)

b. All other sides .................................... 6 in (152 mm)

c. Flue to any combustible surface...... 18 in (914 mm)

Do not use this package heater if any part has been under

water. Immediately call a qualified service technician to inspect

the heater and any gas control which has been under water.

If the 23rd digit in the model number is a “G”, the rooftop unit

was furnished with a factory installed natural gas furnace

(Example: DPSA.....GG3KE). If the 23rd digit in the model

number is a “P”, the rooftop unit was furnished with a factory

installed propane furnace. The Rebel Applied commercial

rooftop units are available in a variety of furnace capacity

and turndown configurations. Reference the DPSA Gas

Furnace Capacity Data section below for configuration-

specific information. DPSA packaged gas heat rooftop units

are designed for outdoor non-residential installations only.

Furnaces to be supplied configured for natural gas OR LP only.

DPSA gas heat furnaces consist of a 439 stainless steel

tubular heat exchanger, in-shot burner manifold with gas valve,

induced combustion blower, gas heat DDC control module, and

all operational safeties. The safety switches include a high-limit

temperature switch, a combustion blower proof of airflow, and

the flame roll-out switch (see

) .

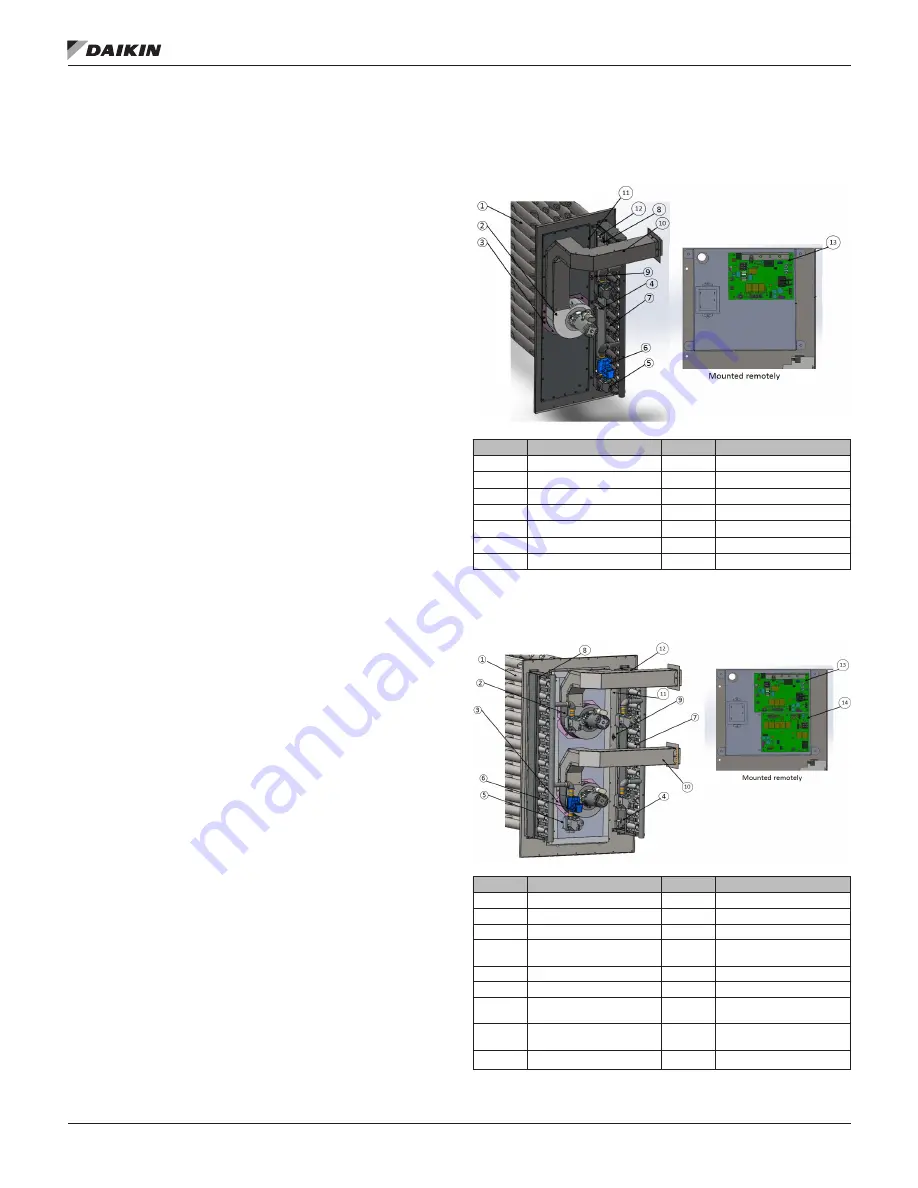

Figure 170: Typical Gas Heat Section Assembly and

Component Identification for Single Flue Furnaces (10:1

600 MBH model shown)

Item

Description

Item

Description

1

Heat Exchanger

8

Rollout switch

2

Inducer blower

9

High limit switch

3

Inducer orifice plate

10

Flue

4

Igniter

11

Pressure switch

5

Gas safety valve

12

Flame sensor

6

Modulating valve

13

Control board

7

In-shot burner

14

Transformer

Figure 171: Typical Gas Heat Section Assembly and

Component Identification for Double Flue Furnaces (10:1

1125 MBH model shown)

Item

Description

Item

Description

1

Heat Exchanger

10

Flue

2

Inducer blower

11

Pressure switch

3

Inducer orifice plate

12

Flame sensor

4

Igniter

13

VB 1285 modulating control

board

5

Gas safety valve

14

VB1287 staged control board

6

Modulating valve

15

Transformer

7

In-shot burner

16

High Temp limit interlock

relay

8

Rollout switch

17

On/off solenoid valve (not

pictured)*

9

High limit switch

*On/off solenoid valve only present in 800 MBH 10:1 or 6:1 furnaces

Summary of Contents for Rebel Applied DPSA

Page 147: ...Figure 181 600 MBH 5 1 Modulation 400 MBH and 600 MBH 10 1 Modulation ...

Page 160: ......

Page 161: ......