13 Piping installation

Installation and operation manual

17

FXFA20~125A2VEB

VRV system air conditioner

3P599604-1C – 2020.10

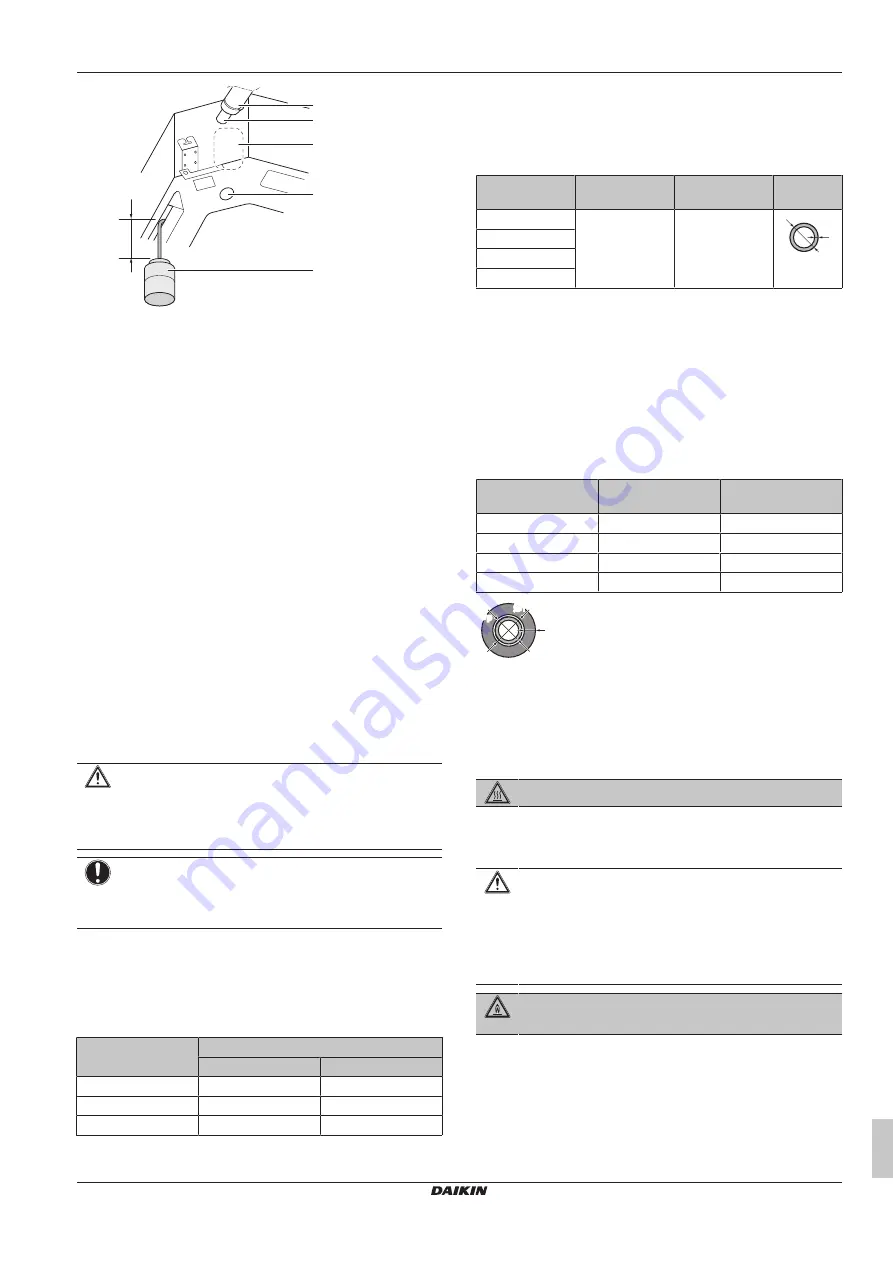

≥100 mm

e

d

c

b

a

a

Plastic watering can

b

Service drain outlet (with rubber plug). Use this outlet to

drain water from the drain pan

c

Drain pump location

d

Drain pipe connection

e

Drain pipe

5

Turn OFF the power.

6

Disconnect the electrical wiring.

▪ Remove the service cover.

▪ Disconnect the power supply.

▪ Disconnect the user interface.

▪ Reattach the service cover.

When installation of the system is already completed

1

Start cooling operation (see the reference guide or the service

manual of the user interface).

2

Gradually pour approximately 1 l of water through the water

inlet, and check for leaks (see

"When installation of the system

16]).

13

Piping installation

13.1

Preparing refrigerant piping

13.1.1

Refrigerant piping requirements

CAUTION

Piping MUST be installed according to instructions given in

17]. Only mechanical joints (e.g.

braze+flare connections) that are compliant with the latest

version of ISO14903 can be used.

NOTICE

The piping and other pressure-containing parts shall be

suitable for refrigerant. Use phosphoric acid deoxidised

seamless copper for refrigerant.

▪ Foreign materials inside pipes (including oils for fabrication) must

be ≤30 mg/10 m.

Refrigerant piping diameter

For piping connections of the indoor unit use the following piping

diameters:

Class

Pipe outer diameter (mm)

Liquid pipe

Gas pipe

20~32

Ø6.4

Ø9.5

40~80

Ø6.4

Ø12.7

100~125

Ø9.5

Ø15.9

Refrigerant piping material

▪

Piping material:

Phosphoric acid deoxidised seamless copper.

▪

Flare connections:

Only use annealed material.

▪

Piping temper grade and thickness:

Outer diameter

(Ø)

Temper grade

Thickness (t)

(a)

6.4 mm (1/4")

Annealed (O)

≥0.8 mm

t

Ø

9.5 mm (3/8")

12.7 mm (1/2")

15.9 mm (5/8")

(a)

Depending on the applicable legislation and the maximum

working pressure of the unit (see "PS High" on the unit name

plate), larger piping thickness might be required.

13.1.2

Refrigerant piping insulation

▪ Use polyethylene foam as insulation material:

▪ with a heat transfer rate between 0.041 and 0.052 W/mK (0.035

and 0.045 kcal/mh°C)

▪ with a heat resistance of at least 120°C

▪ Insulation thickness

Pipe outer diameter

(Ø

p

)

Insulation inner

diameter (Ø

i

)

Insulation thickness

(t)

6.4 mm (1/4")

8~10 mm

≥10 mm

9.5 mm (3/8")

12~15 mm

≥13 mm

12.7 mm (1/2")

14~16 mm

≥13 mm

15.9 mm (5/8”)

17~20 mm

≥13 mm

Ø

i

Ø

i

t

Ø

p

Ø

p

If the temperature is higher than 30°C and the humidity is higher

than RH 80%, the thickness of the insulation materials should be at

least 20 mm to prevent condensation on the surface of the

insulation.

13.2

Connecting the refrigerant piping

DANGER: RISK OF BURNING/SCALDING

13.2.1

To connect the refrigerant piping to the

indoor unit

CAUTION

Install the refrigerant piping or components in a position

where they are unlikely to be exposed to any substance

which may corrode components containing refrigerant,

unless the components are constructed of materials that

are inherently resistant to corrosion or are suitably

protected against corrosion.

WARNING: MILDLY FLAMMABLE MATERIAL

The refrigerant inside this unit is mildly flammable.

▪

Pipe length

. Keep refrigerant piping as short as possible.

▪

Flare connections

. Connect refrigerant piping to the unit using

flare connections.

▪

Insulation

. Insulate the refrigerant piping on the indoor unit as

follows: