5 Piping installation

Installation manual

8

ET9W

Daikin Altherma 3 H HT F

4P644730-1 – 2021.02

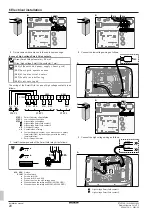

Option 2: Through the right side panel

1

3×

T25

3

2

5

Piping installation

5.1

Preparing water piping

NOTICE

In case of plastic pipes, make sure they are fully oxygen

diffusion tight according to DIN 4726. The diffusion of

oxygen into the piping can lead to excessive corrosion.

NOTICE

Water circuit requirements.

Make sure to comply with the

water pressure and water temperature requirements

below. For additional water circuit requirements, see the

installer reference guide.

▪

Water pressure – Domestic hot water.

The maximum water

pressure is 4 bar. Provide adequate safeguards in the water circuit

to ensure that the maximum pressure is NOT exceeded. The

minimum water pressure to operate is 1 bar.

▪

Water pressure –

Space heating/cooling circuit.

The maximum

water pressure is 3 bar. Provide adequate safeguards in the water

circuit to ensure that the maximum pressure is NOT exceeded.

The minimum water pressure to operate is 1 bar.

▪

Water temperature.

All installed piping and piping accessories

(valve,

connections,…)

MUST

withstand

the

following

temperatures:

INFORMATION

The following illustration is an example and might NOT

match your system layout.

89°C

(*)

75°C

(*)

75°C

(*)

EXAMPLE

(*) Maximum temperature for piping and accessories

5.1.1

To check the water volume and flow rate

Minimum water volume

Check that the total water volume in the installation is minimum 20

litres, the internal water volume of the outdoor unit NOT included.

NOTICE

When circulation in each space heating/cooling loop is

controlled by remotely controlled valves, it is important that

the minimum water volume is guaranteed, even if all of the

valves are closed.

Minimum flow rate

Check that the minimum flow rate in the installation is guaranteed in

all conditions on each zone separately. This minimum flow rate is

required during defrost/backup heater operation. For this purpose,

use the overpressure bypass valve delivered with the unit.

Minimum required flow rate

25 l/min

NOTICE

To guarantee proper operation it is recommended to have

a minimum flow of 28 l/min during DHW.

NOTICE

If glycol was added to the water circuit, and the

temperature of the water circuit is low, the flow rate will

NOT be displayed on the user interface. In this case, the

minimum flow rate can be checked by way of the pump

test (check that the user interface does NOT display error

7H).

NOTICE

When circulation in each or certain space heating loops is

controlled by remotely controlled valves, it is important that

the minimum flow rate is guaranteed, even if all valves are

closed. In case the minimum flow rate cannot be reached,

a flow error 7H will be generated (no heating or operation).

See the installer reference guide for more information.

See the recommended procedure as described in

30].