IM 817-7

38 www.DaikinApplied.com

•

Insulate the suction line piping (minimum heat

.

•

Evacuate and properly charge the refrigerant system,

•

Charge to subcooling at the condensing unit per the

condensing unit manufacturer’s instructions, typically

15°F to 16°F at the unit ventilator, subcooling at

95ºF outdoor ambient (results in correct refrigerant

distribution at the coil to prevent low suction

temperatures)

•

Adjust TXV for correct superheat to eliminate/

•

Set superheat to 5°F to 7°F at the UV coil suction

line when 95°F outdoor ambient (proper system

superheat for optimum performance). Allow system

to settle for 20 to 30 minutes to reach stable steady

state conditions and then recheck/adjust superheat if

necessary, see

•

Compensate both subcooling and superheat for

actual outdoor ambient and indoor air temperatures

•

In windy areas, add wind baffles to condensing unit or

build a parapet (eliminate wind effect on condensing unit

coil for proper TXV refrigerant flow at lower ambient)

•

For lower ambient conditions install variable speed

condenser fan head pressure control to maintain

head pressures between 180psig and 280psig (for

proper TXV refrigerant flow at lower ambient), see

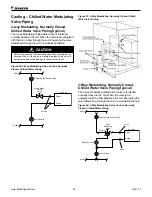

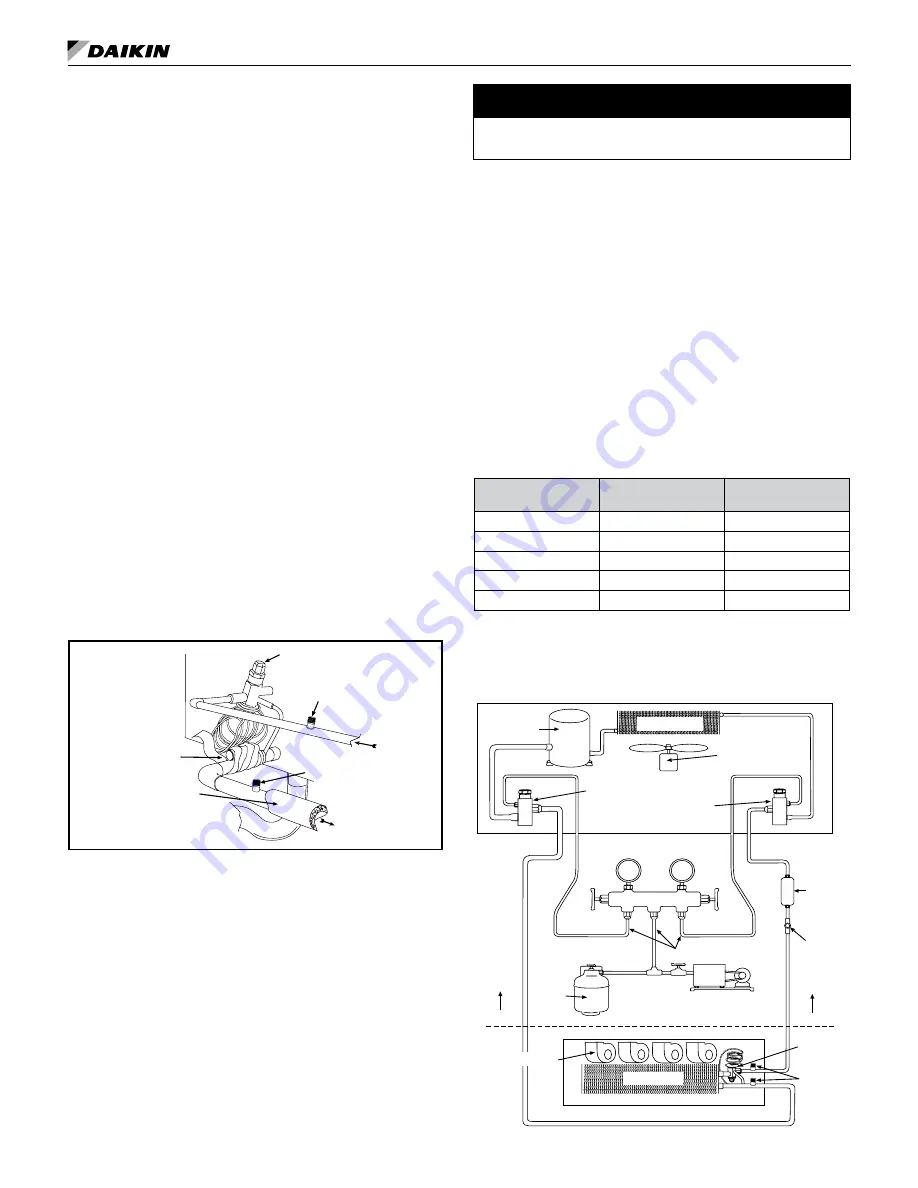

Figure 96: Insulate Bulb and Suction Line Piping

TXV (Thermal Expansion Valve)

Insulate Bulb, (Reacts

To Refrigerant Tempera-

ture and Not Ambient)

Insulate The Suction

Line Piping, (Minimum

Heat Pickup)

Return (Suction Line)

Supply (Liquid Line)

Pressure Taps (Field Installed)

Pressure Taps

(Field Installed)

Checking System Charge

The system charge should be checked under design

conditions [95°F outside air, 80°F/67°F (DB/WB) indoor

air]. Refer to condensing unit manufacturer’s guidelines.

Before adjusting refrigerant charge, verify that the unit

ventilator is operating at normal design cfm. Nominal cfm

is determined with a dry coil, and cfm will be reduced

during air conditioning operation with a wet coil. Filters

and coil must be clean and fan speed set at high.

temperature to obtain subcooling.

NOTICE

Typical conditions - 95ºF ambient, 75 psig suction, 285 psig head

pressure, 6-7ºF superheat, 15ºF subcooling.

Determining Subcooling

To determine correct subcooling:

1 .

Measure outdoor ambient. It must be between 65°F

and 105°F.

2 .

Measure liquid line temperature 6 inches from the

TXV inlet.

3 .

Measure liquid line pressure near the TXV.

4 .

Determine saturated liquid temperature from

saturated temperature pressure chart (

).

5 .

Subtract measured liquid line temperature from

saturated liquid temperature to obtain subcooling.

6 .

Adjust charge per condensing unit manufacturer

recommendation to obtain 15 - 16°F subcooling.

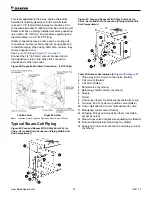

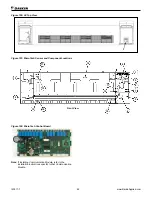

Table 31: Dimensions, DX Tubing inches (mm)

Models AVS, AVV,

AVB, AVR

Suction Line O .D .

Liquid Line O .D .

S07

3/4" (19mm)

1/4" (6mm)

S10

3/4" (19mm)

1/4" (6mm)

S13

7/8" (22mm)

3/8" (10mm)

S15

7/8" (22mm)

3/8" (10mm)

S20

7/8" (22mm)

3/8" (10mm)

piping dimensions are for systems with up to 30

ft. (9.14 m) vertical separation and up to 100 ft

(30.47 m)

horizontal separation from the outdoor condensing unit.

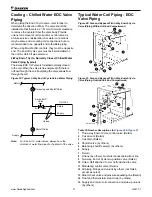

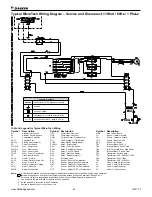

Figure 97: Typical Split System Evacuation/Charging Setup

Liquid

Line

Drier

Sight Glass

Suction Line Service Valve

Liquid Line Service Valve

Outdoor Fan

Compressor

Gauge Bar Hoses

Vacuum Pump

TXV

Indoor Fans

Charging

Cylinder

Indoor Coil

Outdoor Coil

Low Pressure

Gauge

Outdoor Condensing Unit

Unit Ventilator

High Pressure

Gauge

(By Others)

(By Others)

Pressure

Taps

(by others)