4 Installation

Installation manual

11

EABH/9W

Daikin Altherma 3 H W

4P644479-1 – 2020.12

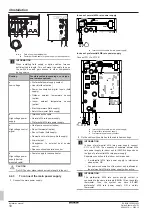

4.4.4

To connect the backup heater power

supply

CAUTION

If the indoor unit has a tank with a built‑in electrical booster

heater, use a dedicated power circuit for the backup heater

and booster heater. NEVER use a power circuit shared by

another appliance. This power circuit must be protected

with the required safety devices according to the applicable

legislation.

CAUTION

To guarantee the unit is completely earthed, always

connect the backup heater power supply and the earth

cable.

The backup heater capacity can vary, depending on the indoor unit

model. Make sure that the power supply is in accordance with the

backup heater capacity, as listed in the table below.

Backup

heater type

Backup

heater

capacity

Power

supply

Maximum

running

current

Z

max

*6V

2 kW

1N~ 230 V

(a)

9 A

—

4 kW

1N~ 230 V

(a)

17 A

(b)(c)

0.22 Ω

6 kW

1N~ 230 V

(a)

26 A

(b)(c)

0.22 Ω

2 kW

3~ 230 V

(d)

5 A

—

4 kW

3~ 230 V

(d)

10 A

—

6 kW

3~ 230 V

(d)

15 A

—

*9W

3 kW

3N~ 400 V

4 A

—

6 kW

3N~ 400 V

9 A

—

9 kW

3N~ 400 V

13 A

—

(a)

6V

(b)

Electrical equipment complying with EN/IEC 61000-3-12

(European/International Technical Standard setting the limits for

harmonic currents produced by equipment connected to public

low-voltage systems with input current >16 A and ≤75 A per

phase).

(c)

This equipment complies with EN/IEC 61000‑3‑11 (European/

International Technical Standard setting the limits for voltage

changes, voltage fluctuations and flicker in public low-voltage

supply systems for equipment with rated current ≤75 A) provided

that the system impedance Z

sys

is less than or equal to Z

max

at the

interface point between the user's supply and the public system. It

is the responsibility of the installer or user of the equipment to

ensure, by consultation with the distribution network operator if

necessary, that the equipment is connected only to a supply with

a system impedance Z

sys

less than or equal to Z

max

.

(d)

6T1

Connect the backup heater power supply as follows:

a

b

X6M

F1B

Q1DI

a

Factory-mounted cable connected to the contactor of the

backup heater, inside the switch box (K5M)

b

Field wiring (see table below)

Model (power

supply)

Connections to backup heater power

supply

*6V (6V: 1N~ 230 V)

1N~, 50 Hz

230 V AC

SWB

4

3

6

5

2

1

K5M

14

13

Q1DI

1

2

3

4

5

6

7

8

F1B

I

I

I

I

N

L

X6M

BRN

GRY

BLU1

BLU2

*6V (6T1: 3~ 230 V)

SWB

3~, 50 Hz

230 V AC

4

3

6

5

2

1

K5M

14

13

1

2

3

4

5

6

7

8

F1B

I

I

I

I

Q1DI

L1 L2 L3

X6M

BRN

GRY

BLU1

BLU2

*9W (3N~ 400 V)

3N~, 50 Hz

400 V AC

SWB

Q1DI

L1 L2 L3 N

1

2

3

4

5

6

7

8

F1B

I

I

I

I

X6M

2

1

K5M

4

3

6

5

14

13

BRN

GRY

BLK

BLU

F1B Overcurrent fuse (field supply). Recommended fuse:

4‑pole; 20 A; curve 400 V; tripping class C.

K5M Safety contactor (in the switch box)

Q1DI Earth leakage circuit breaker (field supply)

SWB Switch box

X6M Terminal (field supply)