S0708315K

Page 33

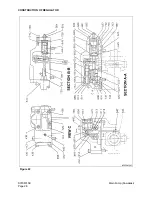

Main Pump (Kawasaki)

Negative Flow Control

By changing the pilot pressure Pi, the pump

tilting angle (delivery flow) is regulated

arbitrarily, as shown in Figure 24.

This regulator is a negative flow control in which

the delivery flow Q decreases as the pilot

pressure Pi rises. With this mechanism, when

the pilot pressure corresponding to the flow

required for the work is commanded, the pump

discharges the required flow only, so it does not

consume unnecessary power.

1.

Functional Explanation

A.

Flow reducing Function

As the pilot pressure Pi rises, the

pilot piston (643) moves to the right to a position where the force of the pilot spring (646)

balances with the hydraulic force.

The groove (A) in the pilot piston is attached with pin (875) that is fixed to lever 2 (613).

Therefore, when the pilot piston moves, lever 2 rotates around the fulcrum of point B (fixed by

the fulcrum plug (614) and pin (875). Since the large-hole section (C, Figure 23) of lever 2

contains a protruding pin (897) fixed to the feedback lever(611), the pin (897) moves to the right

as lever 2 rotates. Since the opposing-flat section (D) of the feedback lever is attached with the

pin (548) fixed by the tilting pin (531) that swings the swash plate, the feedback lever rotates

around the fulcrum of point D, as the pin (897) moves. Since the feedback lever is connected

with the spool (652) via the pin (874), the spool moves to the right.

The movement of the spool causes the delivery pressure P1 to connect to port C liter through

the spool and to be admitted to the large-diameter section of the servo position. The delivery

pressure P1 that is constantly admitted to the small-diameter section of the servo piston moves

the servo piston to the right due to the area difference, resulting in decrease of the tilting angle.

When the servo piston moves to the right, point D also moves to the right. The spool is fitted

with the return spring (654) and is tensioned to the left at all times, and so the pin (897) is

pressed against the large-hole section (C) of lever2. Therefore, as point D moves, the feedback

lever rotates around the fulcrum of point C, and the spool is shifted to the left. This causes the

opening between the sleeve (651) and spool (652) to close slowly, and the servo piston comes

to a complete stop when it closes completely.

B.

Flow Increasing Function

As the pilot pressure Pi decreases, the pilot piston (643) moves to the left by the action of the

pilot spring (646) and causes lever 2 (613) to rotate around the fulcrum of point B. Since the pin

(897) is pressed against the large-hole section (C) of lever 2 by the action of the return spring

(654) via the spool (652), pin (874), and feedback lever (611), the feedback lever rotates around

the fulcrum of point D as lever 2 rotates, and shifts the spool to the left. Port C liter opens a way

to the tank port as the spool moves. This deprives the large-diameter section of the servo piston

of pressure, and shifts the servo piston to the left by the discharge pressure P1 in the small-

diameter section, resulting in an increase in the flow rate.

As the servo piston moves, point D also moves to the left, the feedback lever rotates around the

fulcrum of point C, and the spool moves to the right till the opening between the spool and

sleeve is closed.

Figure 24

Summary of Contents for Solar 300LC-V

Page 2: ......

Page 4: ......

Page 7: ...1SAFETY...

Page 8: ......

Page 46: ...S0102000 Page 38 Track Excavator Safety...

Page 47: ...1SPECIFICATIONS...

Page 48: ......

Page 54: ...S0202080K Page 6 Specifications for Solar 300LC V...

Page 70: ...S0202080K Page 22 Specifications for Solar 300LC V...

Page 71: ...1GENERAL MAINTENANCE...

Page 72: ......

Page 86: ...S0302000 Page 14 General Maintenance Procedures Return to Master Table of Contents...

Page 99: ...1UPPER STRUCTURE...

Page 100: ......

Page 102: ...S0402040K Page 2 Cab TABLE OF CONTENTS Removal 3 Installation 6...

Page 116: ...S0403050K Page 8 Counterweight Return to Master Table of Contents...

Page 140: ...S0407000 Page 6 Swing Bearing...

Page 164: ...S0408070K Page 24 Swing Reduction Gear...

Page 165: ...1LOWER STRUCTURE AND CHASSIS...

Page 166: ......

Page 190: ...S0505000 Page 24 Track Assembly 7 Tighten plug 1 Figure 48 Figure 48...

Page 191: ...S0505000 Page 25 Track Assembly TRACK SPRING AND TRACK ADJUSTING CYLINDER PARTS LIST Figure 49...

Page 193: ...1ENGINE AND DRIVE TRAIN...

Page 194: ......

Page 205: ...S0605060K Page 11 Air Conditioner Face and Defroster ARS1300L Figure 12...

Page 220: ...S0605060K Page 26 Air Conditioner...

Page 229: ...1HYDRAULICS...

Page 230: ......

Page 262: ...S0703010K Page 2 Accumulator TABLE OF CONTENTS General Description 3 Specifications 4...

Page 266: ...S0703010K Page 6 Accumulator...

Page 274: ...S0704080K Page 8 Center Joint Swivel...

Page 283: ...S0705000 Page 9 Cylinders...

Page 287: ...S0705000 Page 13 Cylinders...

Page 291: ...S0705000 Page 17 Cylinders...

Page 299: ...S0705000 Page 25 Cylinders...

Page 308: ...S0705000 Page 34 Cylinders 17 Force out pin bushing 1 from body of cylinder Figure 28...

Page 312: ...S0705000 Page 38 Cylinders...

Page 324: ...S0707270K Page 12 Swing Motor Toshiba MFC200 PARTS LIST Figure 6...

Page 355: ...S0707315K Page 11 Travel Motor with Gearbox...

Page 424: ...S0708315K Page 28 Main Pump Kawasaki CONSTRUCTION OF REGULATOR Figure 22...

Page 444: ...S0708315K Page 48 Main Pump Kawasaki...

Page 450: ...S0709401K Page 6 Main Control Valve Kayaba Figure 1...

Page 451: ...S0709401K Page 7 Main Control Valve Kayaba Figure 2...

Page 453: ...S0709401K Page 9 Main Control Valve Kayaba...

Page 455: ...S0709401K Page 11 Main Control Valve Kayaba Figure 4...

Page 467: ...S0709401K Page 23 Main Control Valve Kayaba Figure 16...

Page 500: ...S0709401K Page 56 Main Control Valve Kayaba Figure 54...

Page 552: ...S0792160K Page 6 Hydraulic Schematic S300LC V...

Page 553: ...1ELECTRICAL SYSTEM...

Page 554: ......

Page 608: ...S0802220K Page 54 Electrical System...

Page 627: ...S0802220K Page 73 Electrical System...

Page 634: ...S0892160K Page 4 Electrical Schematic S300LC V SOLAR 300LC V Figure 2...

Page 636: ...S0892160K Page 6 Electrical Schematic S300LC V...

Page 637: ...1ATTACHMENTS...

Page 638: ......

Page 658: ......