10

1. To remove cabinet

1) Remove three screws on cabinet back.

2) Pull the cabinet backward.

2. To remove door assembly

1) Remove a screw which secure the stopper hinge

top.

2) Remove the door assembly from top plate of cavity.

3) Reverse the above for reassembly.

NOTE : After replacing the door assembly, perform a check of correct alignment with the hinge and cavity front plate.

10

Summary of Contents for KOG-3C6R

Page 5: ...4 EXTERNAL VIEW 1 OUTER DIMENSION 465 384 ...

Page 27: ...26 WIRING DIAGRAM ...

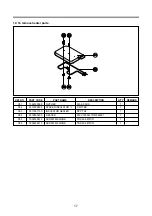

Page 29: ...28 MP1 MP2 Measure Point ...

Page 31: ...30 2 PCB CIRCUIT DIAGRAM ...