Product User’s Manual –

7.4 PACKETIZED SERIAL MODE

In Packetized Serial mode,

is controlled by using the UART interface. Input 1

is the UART Rx pin and Input 2 is not used in this mode. To control the motor, data sent to

the driver must be in 4 bytes packet format which includes a header, address, command and

checksum. Up to 16 units of SmartDrive160 can be connected together to a single

microcontroller UART port.

Besides that, the SmartDrive160 also incorporates an AutoBaud feature in Packetized Serial

mode. When the driver is first powered up, the host microcontroller must send a header byte

(Decimal 85) to the driver. The driver will then calculate the baud rate automatically based on

this character. After that, SmartDrive160 is ready for command and the baud rate cannot be

changed without power off and on again.

NOTE:

1.

When the driver is powered up and waiting for the header byte, the error LED will

blink and indicate that there is input error.

2.

SmartDrive160 may take up to 500ms to start up after power is applied. Sending the

header byte for auto baud during this time period may cause undesirable results. Please

allow a onesecond delay between applying power and sending the header byte.

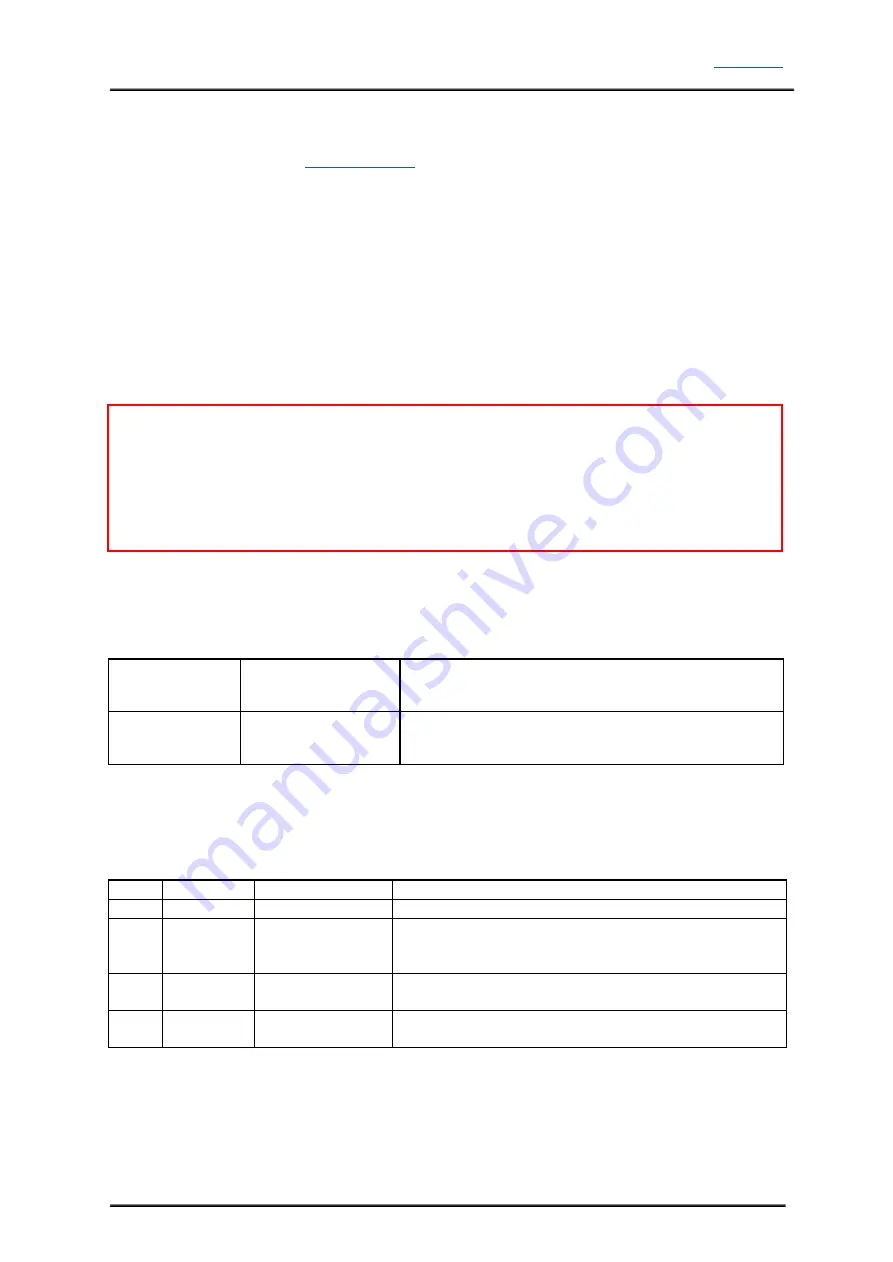

Packetized Serial mode is selected by setting

SW1, SW2 to 0 (Down) and SW3, SW4

to

1

(Up)

. SW5 – SW8 are used to select the address.

Input Mode

SW1 SW4

0011

Packetized Serial Mode

UART Address

SW5 SW8

0000 1111

0 15

0 OFF

1 ON

X Don’t Care

A packet consists of 4 bytes and the format is shown in the following table.

Byte

Name

Value (Decimal)

Description

1

Header

85

To indicate the start of packet.

2

Address

0 15

Used to identify the driver when multiple units are connected

together. The address byte must match the address configured

with the DIP switch.

3

Command

0 – 255

Value 127 stops the motor, 0 is full reverse and 255 is full

forward.

4

Checksum

0 – 255

The value for checksum must be the result of

A Command

Created by Cytron Technologies Sdn. Bhd. – All Rights Reserved

17