- 3 -

SETTING THE WC-603-101 BREW TIMER

Adjustment of the timer is made on a calibrated dial with a range from 0 to 100.

This is a range of 2 to 20 minutes. The front control panel has a brew selector

switch marked

1

and

2

.

To change the setting, flip the brew selector switch to

2

. Locate the brew timer, in-

side the top cover. Rotate timer arrow to the right to increase the brew time, rotate

to the left to decrease the brewing time. The indicator dial is normally set pointing

at 25. This setting is intended to deliver one gallon of water (brew 24 cups) per

brew cycle..

Cleaning the Satellite Server

1. Empty any remaining coffee from the Satellite server.

2. Fill the liner with a mild detergent solution and let it stand for 10 to 15 minutes.

3. After about 15 minutes take a sponge brush and scrub out the stainless steel liner.

4. Drain out the detergent solution from the server. Rinse in a sink with running water.

5. Repeat this rinsing until the water runs clear.

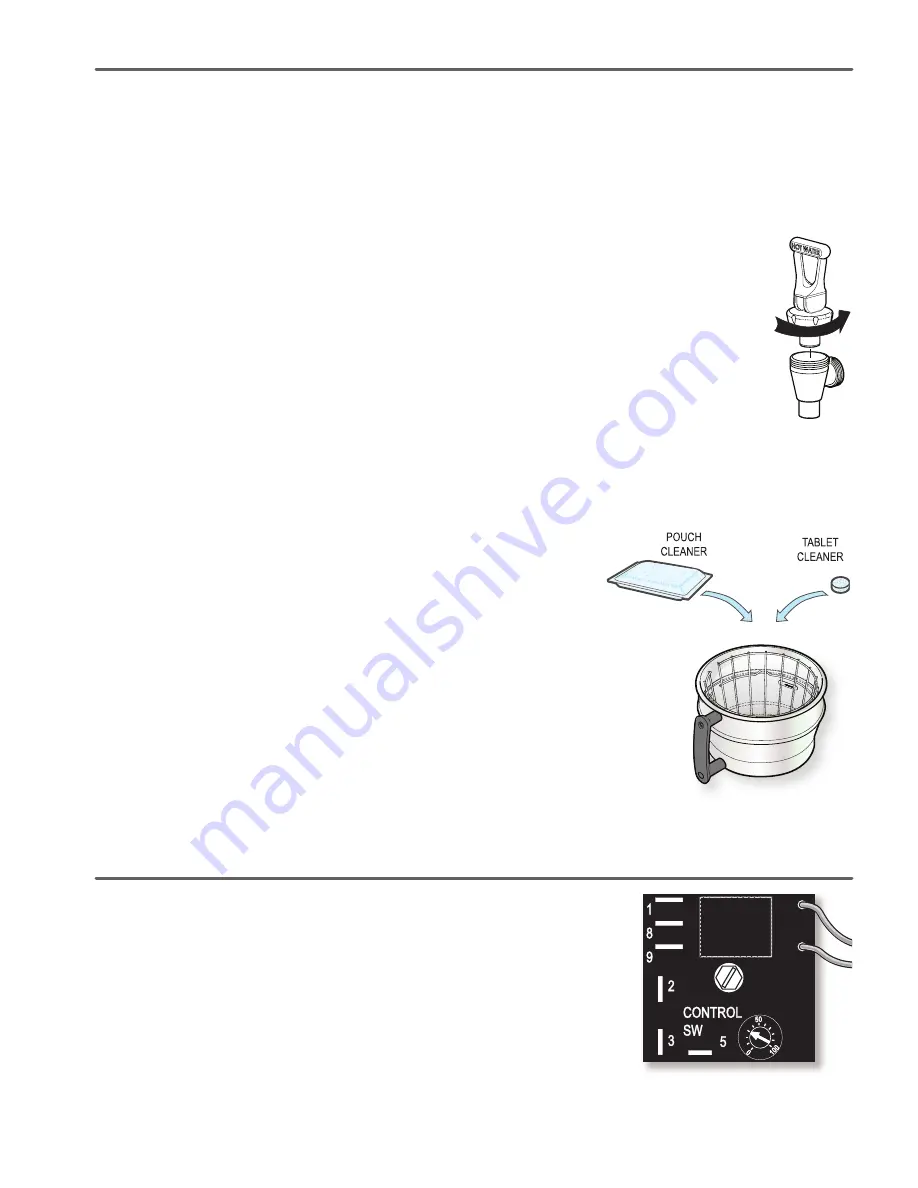

CLEANING THE FAUCET

1. Remove the faucet handle assembly. Take hold of the bonnet and turn counterclockwise to unscrew it from the faucet.

2. Clean the handle assembly with a mild detergent solution. When clean, rinse the handle with water. Inspect for cracks

or tears in the seat cup. Replace if the seat cup damaged.

3. Clean the coffee level gauge glass.

a. Remove the gauge glass cap unscrewing it from the top of the shield.

b. Carefully, pull out the gauge glass. Brush out the inside of the glass with a detergent solution. Rinse the sight glass

tube of all detergent residue.

c. Inspect the gasket seals at the top and bottom of the gauge glass. Clean these gaskets.

d. Assemble the gauge glass. Make sure gaskets are properly seated.

e. Hand tighten the gauge glass cap.

Pouch Cleaner

You may use a pouch or tablet cleaner to easily clean both the brew cone and the coffee vessel.

1. Place a pouch or tablet cleaner into the brew cone. Place an empty server on the brew

deck.

2. Press the brew button to run a full brew cycle into the server. You will see that the

cleaner pouring from the brew cone is blue.

3. At the end of the brew cycle, discard the used filter cleaner pouch. The tablets should have disolved in

the brew cycle.

4. Allow the cleaner to soak in the coffee server for a few minutes.

5. Dump out the cleaner from the coffee server into a sink. You can simply open the faucet and let the

blue cleaning solution to flow out.

6. Return the empty coffee server to the brew deck. Install the brew cone onto the brewer. Run another

brew cycle of hot water to rinse the brew cone and into the server.

7. Empty the rinse water from the coffee server. Repeat the rinse cycle before putting the coffee server

back into service.