JetScan iFX

®

i100 Scanner

All Models

42

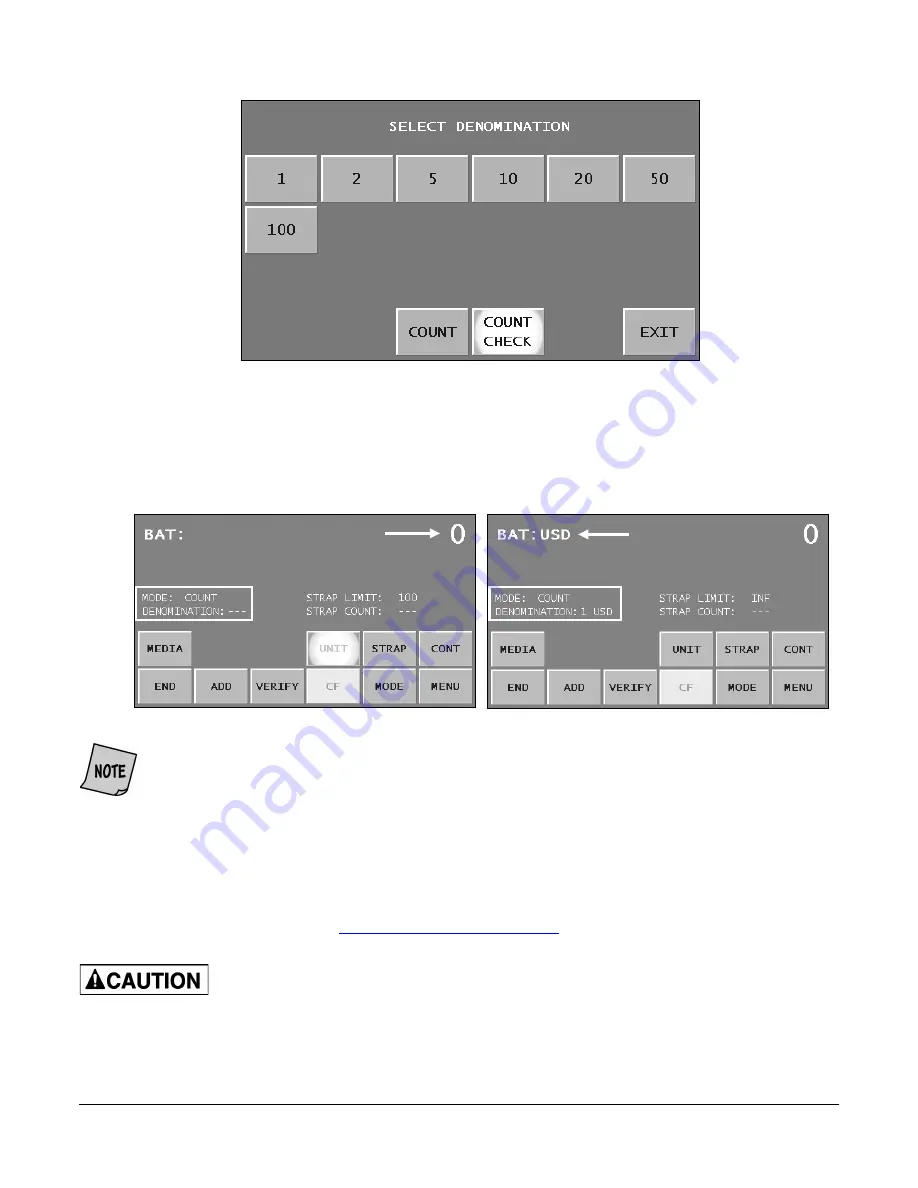

4.

To piece count, press

COUNT

. To value count, press the appropriate

denomination value key

.

To count checks, press the

COUNT CHECK

key

.

5.

Press

EXIT

to return to the main screen.

Piece-Count Screen Value-Count Screen

When using value count:

•

The piece count may be viewed by pressing UNIT on the main screen. The piece count

appears in the upper-right corner.

•

The International Organization for Standardization (ISO) abbreviation for the active

currency appears after BAT, as shown above.

6.

Press

ADD

on the main screen to accumulate batch totals if desired.

7.

Set strap limits if desired.

(See

)

Machine is auto-start capable. Feed rollers in hopper rotate inward.

Entanglement and drawing-in hazard.

Do not operate with exposed long hair, neckties, jewelry or loose clothing.

Summary of Contents for JetScan iFX i100

Page 1: ...JetScan iFX i100 Scanner Operating Instructions for All Models ...

Page 121: ......