18

S

ection

6— M

aintenance

& a

djuStMentS

Drive Control

When the drive control is released and in the disengaged “up”

position, the cable should have very little slack. It should NOT be

tight.

NOTE:

If excessive slack is present in the drive cable or if the snow

thrower’s drive is disengaging intermittently during operation,

the cable may be in need of adjustment.

Check the adjustment of the drive control as follows:

1.

With the drive control released, push the snow thrower

gently forward. The unit should roll freely.

2.

Engage the drive control and gently attempt to push the

snow thrower forward. The tracks should not turn. The unit

should not roll freely.

3.

With the drive control released, move the shift lever back

and forth between the R2 position and the F6 position

several times. There should be no resistance in the shift

lever.

If any of the above tests failed, the drive cable is in need of

adjustment. Proceed as follows:

1.

Shut off the engine as instructed in the separate engine

manual.

2.

Loosen the hex jam nut on the drive control cable “Z”

fitting.

3.

Thread the ferrule without turning the cable onto the “Z”

fitting until there is no slack in the cable. See Figure 6-7. Do

not overtighten the cable. Hold the flats on the ferrule with

pliers and tighten the jam nut against the ferrule.

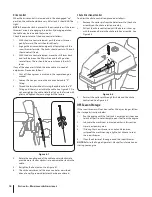

Figure 6-7

4.

Rotate the coupling end of the cable counterclockwise to

provide more slack or clockwise to decrease the slack in the

cable.

5.

Retighten the hex jam nut. See Figure 6-7.

6.

Check the adjustment of the drive control as described

above to verify proper adjustment has been achieved.

Chute Directional Control

To adjust the chute control rod, proceed as follows:

1.

Remove the cotter pin from the hole closest to the chute

assembly on the chute rotation assembly.

2.

Pull out the chute control rod until the hole in it lines up

with the second hole in the chute rotation assembly. See

Figure 6-8.

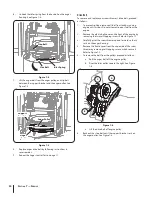

Figure 6-8

3.

Reinsert the cotter pin through this hole and the chute

control rod. See Figure 6-8.

Off-Season Storage

If the snow thrower will not be used for 30 days or longer, follow

the storage instructions below.

1.

Run the engine until the fuel tank is empty and it stops due

to lack of fuel. Do not attempt to pour fuel from the engine.

2.

Lubricate the machine as instructed earlier in this section.

3.

Store in a clean, dry area.

4.

If storing the snow thrower in an unventilated area,

rustproof the machine using a light oil or silicone to coat

the snow thrower.

5.

Clean the exterior of the engine and the snow thrower.

NOTE:

Refer to the Engine Operator’s Manual for information on

storing your engine.

Summary of Contents for 2X 728 TDE

Page 26: ...Notes 11 26 ...

Page 27: ...27 Section 11 Notes ...