7

gyro is a good time to check the condition of tail drive gears, belts, pulleys

etc. Inspect them regularly to ensure that they are in good condition.

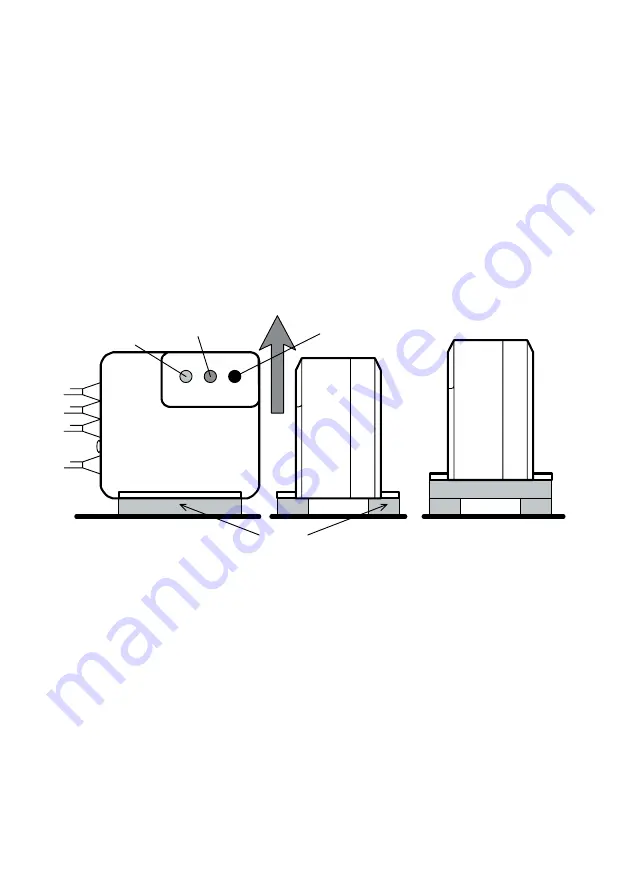

Mounting the gyro

The gyro may be mounted lengthways (longitudinally) or across

(transversely) within the model however it should have its axis of rotation

(as marked on the back of the gyro case) parallel to the main shaft of the

helicopter. For setting up you will need to see the LEDs so mount the gyro

where these can readily be seen.

Axis of rotation

Make this parallel to the

Attach to helicopter using two of the self-adhesive foam strips provided

SERVO

RUD. IN

GAIN

PWR

REV

SL

560

GYRO

Power indicator LED

Gyro sense reverse LED

(red)

(yellow)

Mount gyro where

these are visible

main shaft of the helicopter

Indicator LEDs

For high vibration environment

use four strips as shown.

SUPER

SERVO

Super Servo LED

(green)

PC

Figure 2.

Gyro orientation

The gyro sensor (together with the electronics of the gyro) is anti-vibration

mounted inside the gyro case. However, to provide further vibration and

shock resistance it is important that the gyro be mounted to the airframe

using two of the double sided adhesive foam strips provided. Do not use

any other type of mounting foam as this will reduce the performance of

your gyro. Replacement strips are available as a CSM spare. For good

adhesion, ensure that the surface to which the gyro is attached is smooth,

hard and clean. As with all high performance solid state gyro systems, the

SL560 performs best if sited at a point of low vibration in the helicopter

airframe. Where possible avoid siting the gyro at the extreme front of the

radio tray for example as this area is often subject to high levels of main

rotor generated vibration. Also many plastic radio trays are too flexible and