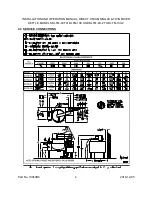

INSTALLATION AND OPERATION MANUAL, DIRECT STEAM SINGLE & TWIN MIXER

KETTLE, MODELS DLTM-40 TO DLTM-100 AND DLTM-40-2 TO DLTM-100-2

3.0 INTRODUCTION

DESCRIPTION

All Crown direct connected steam jacketed kettles pertaining to this manual are direct steam

operated pressure vessels of a double-wall stainless steel construction forming a steam

chamber (jacket) enveloping the lower two thirds of the kettle bowl surface. All kettles are

tilting, floor mounted in fixed positions on legs with adjustable flanged feet. All kettles are

equipped with a safety relief valve and a steam control valve.

CAPACITIES

All models are suffixed with either -40, -60, -80 or -100 to indicate the capacity of that kettle in

US gallons. Thus a DLTM-40 is a two thirds jacketed direct steam kettle mounted on legs with

a capacity of 40 gallons (US).

FUNCTIONING MODE

Crown direct connected steam jacketed kettles consist of a stainless steel bowl and a stainless

steel jacket which envelopes two thirds of the lower surface of the bowl thus forming a sealed

pressure vessel (chamber) into which steam is introduced by means of a manual control valve.

The kettle bowl is the container for the food product which ideally should be of a liquid or semi-

liquid consistency to achieve complete contact with the bowl surface and thus fully absorb the

heat transmitted through that surface.

The temperatures required for the cooking process to function adequately must be greater than

the boiling point of the liquid food product. Further, the greater the steam pressure used, the

higher the temperature and consequently the quicker the cooking process. For example, steam

pressurized at 30 psi attains a temperature of 274 degrees Fahrenheit (135 Celsius).

In the initial stages of the cooking process when the steam comes in contact with the cold kettle

bowl surface it condenses and forms considerable amounts of water. A thermostatic steam

trap should be plumbed to the exit end of the kettle jacket. This trap is a mechanical device

that closes on high temperatures and opens when the temperature drops thus allowing the

water formed from condensate to exhaust but retain steam under pressure.

Part No. 10040R4

6

2018-12-05