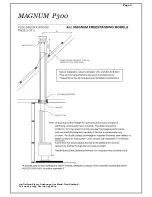

A SMALL-STACKED FUEL

LOAD Good for short-duration

fires

A LARGE-STACKED FUEL LOAD

Good for extended burning cycles

Small and Large Fuel Load Geometry

Fire in cycles:

Don't expect perfectly steady heat output

from your Magnum heater. Solid fuel heaters burn best in

cycles. A cycle is the time between the ignition of a load

from dry wood and the consumption of the load back to an

ember bed. Each cycle should provide between four and

eight hours of heating, depending on how much wood was

used and how much heat is needed. Plan the firing cycles

around your household routine. If someone is home to

operate the heater, build a small hot fire. If you must be

away from the house during the day, build a long-burning

fire.

The small, hot fire:

A small, hot fire is a small amount of

wood burned quickly. Use it when you just want to take

the chill off the house. The small hot fire technique eliminates the smouldering fires that are

common when people don’t need their heater running hot all the time, like in spring and autumn.

To build a small hot fire, rake the embers towards the front of the fire and place several small

pieces on it. The bottom layer should be placed to ensure that combustion air can flow over the

embers and along the length of the pieces of wood. The next layer should be stacked loosely in a

crisscross arrangement. Open the air inlet to produce a hot, bright fire. After approximately 15–20

minutes the air supply can be reduced slightly as the fire progresses, but never enough to

extinguish the flames. When only embers remain, the air supply can be reduced further to prevent

cooling the ember bed.

The long-burning fire:

To achieve a long burning fire, rake the embers towards the air inlets, as

with the small hot fire, and use larger and more pieces of wood. Place the pieces in a similar

pattern to the small hot fire, using more pieces and larger pieces (especially the top layer).

Always make certain that there is a gap between the pieces to ensure that the combustion

air can reach all pieces

. Open the air inlets fully for between 15 to 30 minutes depending on

load size and fuel moisture content. When the fire is burning fiercely (at least 15 minutes), reduce

the air control in stages to the desired level. This allows you to turn down the air control and still

maintain a clean-burning fire.

REMEMBER: NEVER LET THE FIRE SMOULDER.

Preventing creosote build-up:

Creosote is a tar-like substance that builds up when the organic

compounds in smoke mix with moisture in the firewood and condense onto cooler flue surfaces.

Left to build up over time, creosote will restrict the airflow of the flue and impair the performance of

your heater. The production of smoke is at its highest when a fresh fuel load is added or when the

air control is at its lowest position. The most effective way to control the creosote formation is to

burn the heater so as to ensure as complete combustion as possible and at the same time

promoting higher flue temperatures. Smouldering fires should always be avoided.

The amount of charcoal in the ash is often a good indicator of how well you are operating the

heater. If there is no charcoal and only very fine ash, then you are doing an excellent job.

LOADING FOR A SMALL HOT

FIRE

Rake the embers towards the front of the fire. Load

the wood loosely in a crisscross arrangement. Let

the fire burn brightly until most of the solid wood is

burned before reducing the air setting.