7

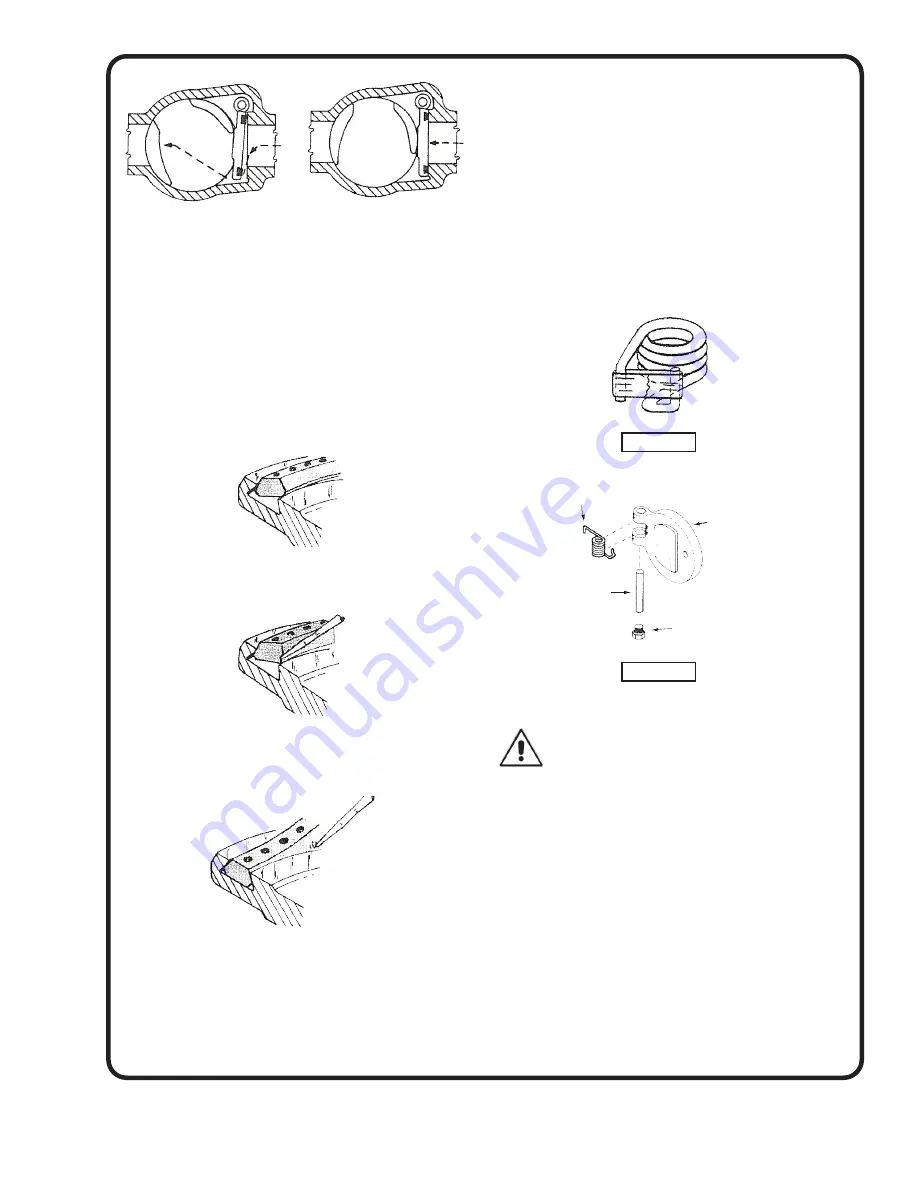

REPAIR CLAPPER SEAL:

HVAC TDV valves are equipped with Buna-N clapper

seals. If the clapper seal is damaged, they can be

replaced by removing the clapper and installing a new

seal (see steps 1-3 below).

Step 1

Place the outer edge of the seal into the clapper groove

as shown.

Step 2

Using a blunt screwdriver, force the inside lower edge of

the seal into the clapper groove.

Step 3

As you work the seal in, maintain force on the portion

of the seal that has been installed. This will prevent

elongation and excessive build-up of closing portion.

REPLACEMENT PROCEDURE:

1.

Position clapper firmly against the seat face.

2.

Pre-load spring and bind using filament tape (see

Figure 4a)

3. Take the clapper pin with the extension screw and

insert the pin into the spring and support hangers (see

Figure 4b)

4.

When holding the clapper firmly against the seat, the

clapper pin must move freely into position.

5. Remove the extension screw, replace the clapper pin

plug, and cut the filament tape to free the spring.

6. Check the clapper for free movement by opening and

closing the clapper by hand.

7. If movement is free, complete the valve assembly.

6. WIRING

WARNING: DO NOT START PUMP UNTIL IT

HAS BEEN FILLED WITH WATER.

1. Motor wiring should conform to national and local

electrical codes.

2. Use wire of adequate size to prevent voltage drop.

3. Pump should be on a branch or separate circuit,

fused or circuit breaker, protected, with a manual

disconnect.

4. Connect the electrical supply from the switch to the

motor terminals, following the wiring diagram on

the motor nameplate or terminal cover plate.

NOTE:

be sure that the connections to the motor

terminals correspond with the voltage to be

applied. (See Chart)

Check wiring and fuse charts before connecting wires to

service line. Make sure the voltage and frequency of the

electrical current supply agrees with that stamped on the

motor nameplate. If in doubt, check with power company.

Closed Position

As the plug is rotated

toward the closed position,

the downstream part

closes first. This equalizes

the Pressure so the

clapper closes with little

resistance.

Positive Seal Closure

Final closing is

accomplished by the plug

camming against the back

of the clapper.

Figure 4a

Spring

Figure 4b

Clapper Pin Plug

Clapper

Clapper Pin