8

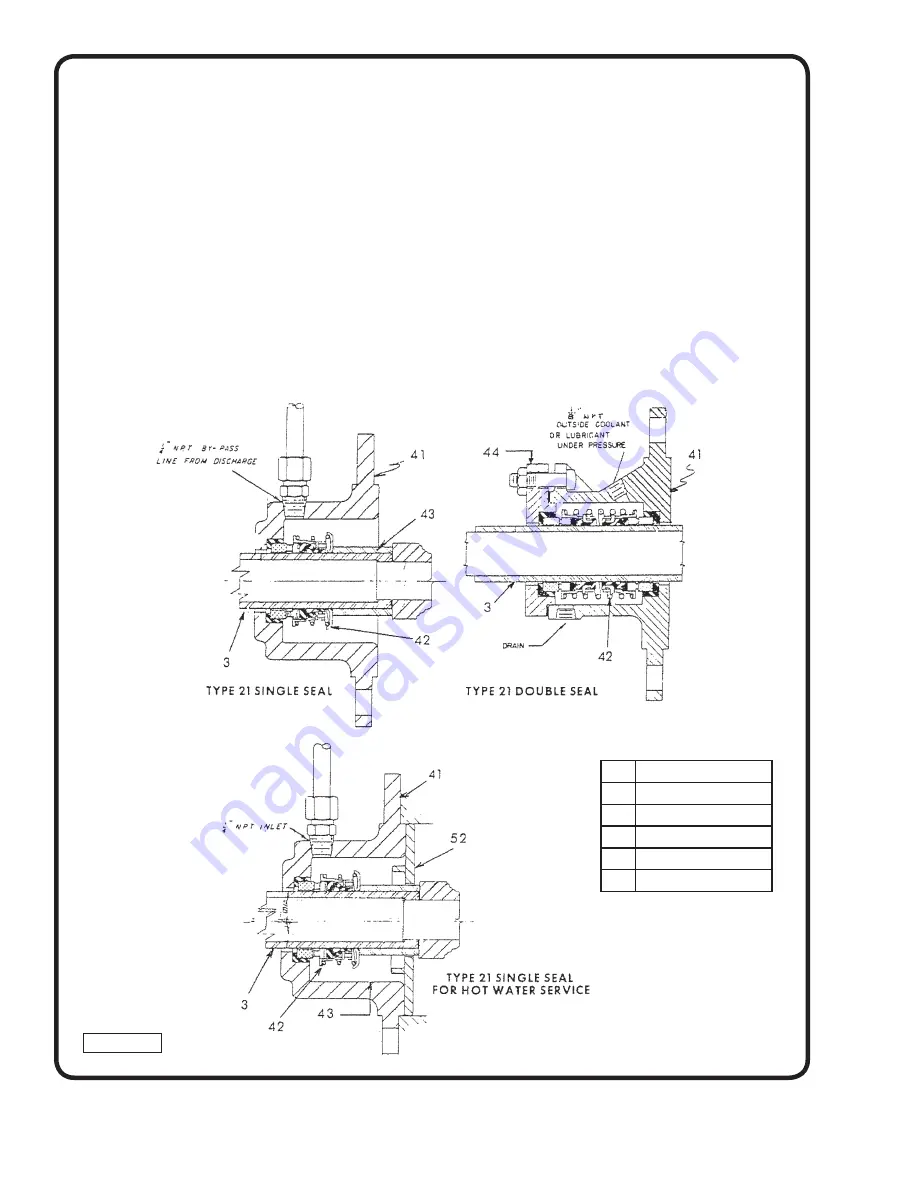

5. REPLACE DOUBLE MECHANICAL SEAL

- Seals are

available as a complete assembly only.

a. The double mechanical seal as shown is used

when pumping abrasives or nonlubricating liquids

or with liquids at excessive temperatures.

A sealing liquid at 15 to 20 pounds above suction

must be circulated through the seal chamber.

Clear water under pressure can be used in most

applications as a sealing liquid for lubrication and

cooling. If the pressure at the inner seal face is

under 25 pounds and the temperature is under

boiling point of the liquid being pumped, the seal

chamber can be fi lled with grease. See

“Lubrication”, a spring loaded compression type

grease cup should be installed to maintain

pressure in the seal chamber.

b. Special precautions must be observed when

handling a mechanical seal. DO NOT drop the

seal face carbons or fl oating seats nor scratch

the lapped faces for these pieces.

c. To remove the seal assembly, dismantle the

liquid end of the pump as described in

“Disassembly of Liquid End”, then unscrew gland

bolts and nuts. Remove seal head casting (41)

from the motor support, exposing the seal

assembly. Grasp the seal fi rmly by hand and

twist it on the shaft to break the seal between

the bellows and the shaft. The seal can now be

pulled from the sleeve. Also remove the seal

gland (44) from the shaft. Place gland gasket in

water. Press seal seats from the seal gland (44)

and seal head (41).

Figure 4

3

Shaft Sleeve

33

Shaft Sleeve

41

Seal Head

42

Seal Assembly

44

Seal Gland

52

Insert Choker Ring