English

10

when turning toward the rear of the grinder and loosen

when turning toward the front of the grinder.

6. Remove the hex nut

26

, the outside wheel flange

27

and the wheel

8

.

7. Inspect the wheel

8

for cracks, chips or any other visible

damage (other than normal wear) and discard if such

damage is found. Inspect the blotter/cardboard disc for

damage. If the blotter id missing or severely damaged,

replace it withe a piece of thin cardboard of blotter

paper cut in the same shape. NEVER USE A GRINDING

WHEEL WITHOUT A BLOTTER.

8. Install the new wheel and make sure both wheel

flanges

27

,

28

are in place with the concave sides

toward wheels.

9. To prevent wheel rotating, place a wood wedge

25

(not

supplied) between the wheel and the wheel cover as

shown in Fig. K.

10. Tighten the hex nut

26

by an adjustable wrench.

nOTE:

Do not overtighten the nut as this can crack the

grinding wheel.

11. Replace the wheel cover

24

and screws

22

.

12. Reinstall and adjust the tool rest to 1/16 in. (1.6 mm)

away from the wheel and tighten securely.

13. Adjust the eye shield

10

to a point between your eyes

and the wheel.

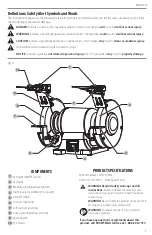

Fig. G

Fig. H

22

24

25

23

10

9

7

6

Mounting The Tool On A Workbench (Fig. L)

nOTE:

FIRMLY BOLT THE GRINDER TO A WORK BENCH OR

LEG STAND to gain maximum stability for your machine.

1. Using the base of the bench grinder as a template, mark

the bench through two holes

29

in the casting.

2. Bolt the bench grinder on the bench with bolts, washers

and nuts.

nOTE:

The mentioned fasteners are not supplied with

the machine.

Fig. I

25

26

Fig. J

26

27

8

28

loosen

Fig. K

26

25

tighten