Reviews:

No comments

Related manuals for 351.227240

5300

Brand: NAD Pages: 9

N1923B

Brand: Makita Pages: 60

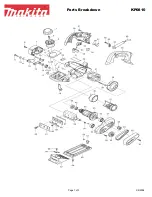

KP0810

Brand: Makita Pages: 11

KP0810

Brand: Makita Pages: 3

KP0800

Brand: Makita Pages: 8

1912B

Brand: Makita Pages: 3

1911B

Brand: Makita Pages: 44

1900B

Brand: Makita Pages: 12

1902

Brand: Makita Pages: 2

KP312

Brand: Makita Pages: 3

XCH 6RF

Brand: Jensen Pages: 8

CD-26

Brand: Jensen Pages: 7

ALIO CD-DAB

Brand: Tangent Pages: 144

KH 2262

Brand: E-Bench Pages: 12

CD50 mk2

Brand: Creek Audio Pages: 12

R3903663

Brand: Volvo Pages: 11

AZ1021

Brand: Philips Pages: 2

Soundmachine AZ3014

Brand: Philips Pages: 2