30

31

30

31

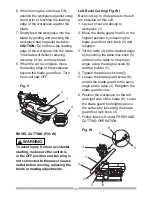

INTERIOR CUTTING (FIG. Y)

1. Lay out the design on the workpiece

(1). Drill a 1/4 in. hole (4) in the

workpiece .

2. Remove the blade by turning the

tension knob (2) counterclockwise.

Refer to BLADE REMOVAL AND

INSTALLATION.

3. Place the workpiece on the saw

table with the workpiece hole (4)

over the access hole in the table (5).

4. Install the blade (3) through the hole

in the workpiece and tighten the

tension knob (2).

5. Follow the process, items 3-8,

under FREEHAND CUTTING

OPERATIONS.

6. When finished making the interior

scroll cuts simply turn the scroll

saw OFF, remove the blade from

the blade holder and remove the

workpiece from the table.

Fig. Y

3

4

5

1

2