14

¾

BACK At such item, move the joystick right or left to display

the submenu (MAIN MENU)

2.6.2

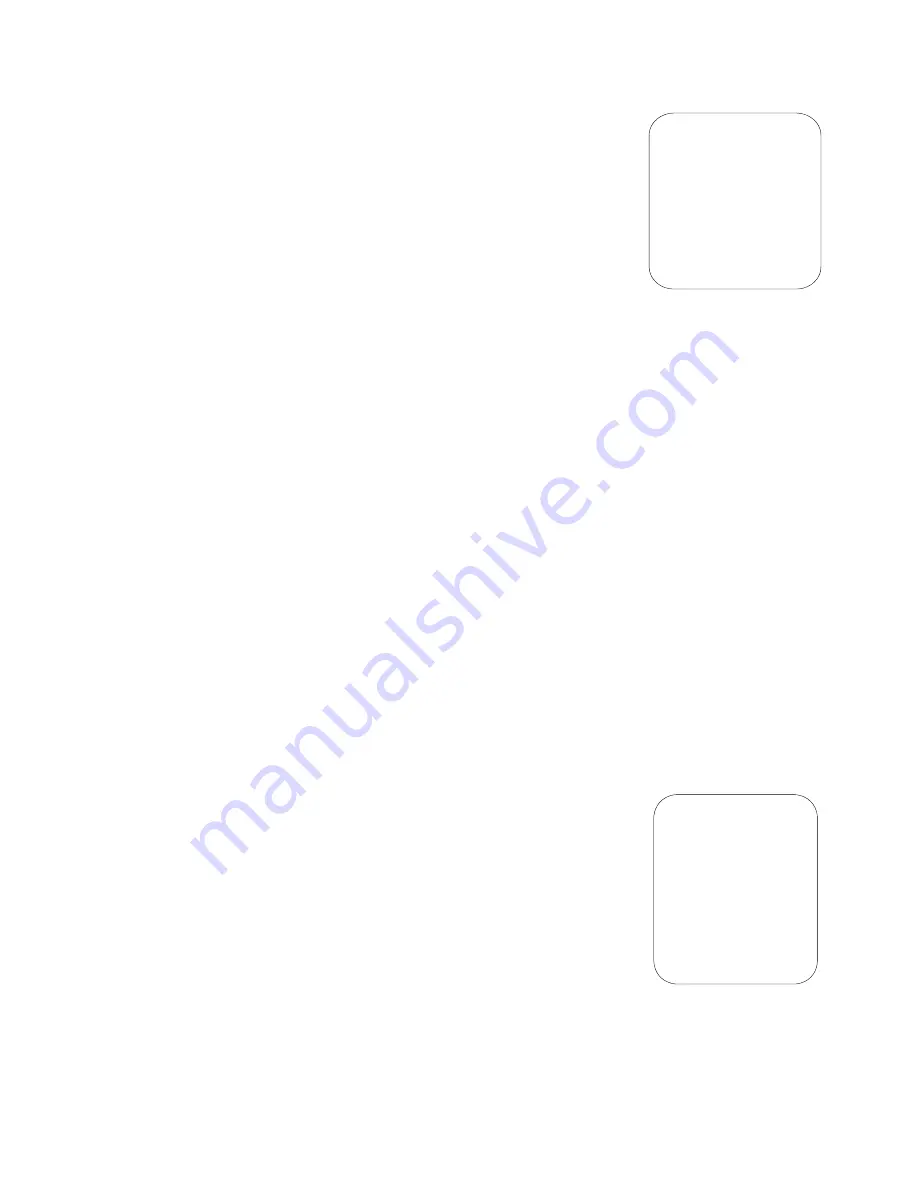

CAMERA SETTUP

At the main menu item “CAMERA

SETTUP”, move the joystick right to display the submenu

“CAMERA SETTUP”. Move the joystick up or down to choice the

menu item and move the joystick right or left to setup the parameter.

¾

BACK LIGHT

moves the joystick at such item right or left to

switch the back light ON/OFF.

¾

ICR SHOT

move the joystick at such item right or left to switch the ICR SHOT

ON-AUTO.

¾

IRIS

move the joystick at such item right or left to switch the IRIS

AUTO-MANUAL.

¾

D-ZOOM

move the joystick at such item right or left to switch the Digital

ZOOM ON-OFF.

¾

FOCUS

move the joystick at such item right or left to switch the FOCUS

AUTO-MANUAL

¾

WB

move the joystick at such item right or left to switch the WHITE BALANCE

SET among AUTO—MANUAL—OUTDOOR—INDOOR—ATW—ONEPUSH.

¾

OSD OF CAM

move the joystick at such item right or left to switch the menu

or screen ON/OFF.

¾

BACK

move the joystick at such item right or left to return MAIN MENU

2.6.3 PROGRAM

At the main menu item “PROGRAM”, move the joystick right to

display the submenu “PROGRAM”. Move the joystick up or down to choice the

menu item, and move the joystick right or left to setup the parameter.

¾

SET AP START POT

move the joystick at such item right or

left to set the current position of Pan/Tilt or dome as the start

point of the line scanning.

¾

SET AP END POT

move the joystick at such item right or left

to set the current position of Pan/Tilt or dome as the start point of

the line scanning.

¾

RUN AP

move the joystick at such item right or left to run the

line scanning from the start point to the end point.

¾

SET PATROL

move the joystick at such item right or left to change the tracking

number among 01-06. To press OPEN to enter the submenus of tracking edit. At

CAMERA SETTI NG

1.BACK LI GHT

2. I CRSHOT

3.

D- ZOOM

4.

I RI S

5. FOCUS

6. WB

7. OSD OF CAM

8. BACK

PROGROM

1.SET AP START POT

2. SET AP END POT

3. RUN AP

4. SET PATROL

5. RUN PATROL

6. SET PATTERN

7. RUN PATTERN

8. BACK