Teledyne Continental Motors, Inc.

TM

Troubleshooting

IOF-550 Permold Series Engine Maintenance Manual

8-13

1 April 2007

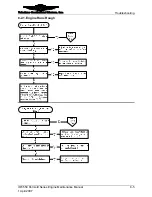

Procedure

1.

Connect the FADEC Level I Diagnostic interface cable 9-pin serial connector to an

available serial port on the computer.

2.

Connect the interface cable in the stand alone FADEC Serial Data Port or EDI Serial

Data Port.

3.

Power-up the computer.

WARNING

Before engine start, ensure the propeller rotational arc is clear

or personnel or obstructions to avoid injury or equipment

damage.

4.

Master Power Switch .....................................ON

5.

FADEC Primary Power Switch .....................ON

6.

FADEC Secondary Power Switch .................ON

RESULT: FADEC WARNING and CAUTION lamps illuminated.

7.

Launch the FADEC Level I Diagnostic application and follow the onscreen prompts.

8.

Select the “Health Status” page in the Level I Diagnostics program.

9.

Review the Health Status indicators for system fault indications. Faults are presented

in a “plain English” format. Tables after this procedure explain Health Status faults.

10.

Start the engine and allow normal warm up (OI-24, Chapter 7). Monitor the “Health

Status” page for fault indications.

11.

Monitor the Health Status page

a.

Perform an “Engine Operational Check” according to Chapter 6 instructions.

b.

Throttle........................................ Wide Open

c.

Throttle................................................. IDLE

d.

If system faults are observed at any point during this test, troubleshoot to identify

and correct faults.

12.

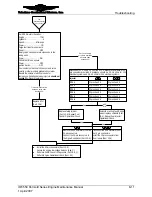

Select the “View Raw Data” page.

NOTE: ECU channels display values for each parameter. For

example, if the displayed Pm value for Channel 1 is 12.1 psia,

acceptable values for Channels 3 or 5 are between 11.35 – 12.85

psia. If the difference for a shared parameter exceeds specified

limits, troubleshoot to identify and correct the malfunction.

Table 8-2.

FADEC Sensor Deviation Range

Parameter Tolerance

+/-

Pf 5.0

psia

Pm 0.75

psia

Tm 10°F