November 2011

72-30-03

PROTECTION FROM CORROSION:

Coat all steel parts with corrosion preventive oil. At

inspection, parts are wiped free of oil, to provide easy handling and true dimensional readings.

Immediately after inspection, parts must be cleaned to eliminate fingerprints and contaminants,

completely recoated with corrosion preventive oil and packaged properly to prevent damage.

72-30-02

VISUAL INSPECTION

Perform a visual inspection on all parts not specified as 100% replacement at overhaul.

Examine parts prior to being cleaned for obvious evidence of wear or leakage. Reject obviously

damaged parts during the preliminary visual inspection, there is no need to clean and perform

non-destructive inspection on parts which cannot be used. If condition is uncertain, clean with

remaining parts after the preliminary exam, according to the “Engine Cleaning” instructions in

Section 72-20. Verify the parts are clean and free of all dirt, carbon, varnish, gum, and paint.

1. Visually inspect the parts using at least a 10X (power) magnifying glass under good lighting

for unacceptable conditions, such as

nicks, dents, gouges, cracks, distortion, burned areas,

pitting, metal transfer, corrosion, erosion and enamal coating wear.

Inspect all studs for bending,

looseness or partial removal.

2. Inspect all threaded parts for nicks, damaged or deformed threads, faces, or heads.

3. Identify areas that warrant further cleaning.

4. Label parts which fail inspection; indicating reason for failure and if repair is possible or if

replacement is required.

5. After visual inspection, parts should be in three groups, potentially serviceable parts,

reparable parts and parts to be discarded.

72-30-03

MAGNETIC PARTICLE INSPECTION

Prior to performing a Magnetic Particle Inspection, verify the parts are clean and free of dirt,

carbon, varnish, gum, and paint.

CAUTION... Prior to Magnetic Particle Inspection, ensure that the parts have

been thoroughly cleaned and dried according to “Engine Cleaning” instructions

in Section 72-20.

NOTE... Magnetic Particle Inspection of filler tubes, balance tube

brackets and any cover is not required.

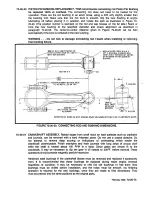

The Magnetic Particle Inspection must be performed by a certified technician on cleaned,

ferrous parts according to ASTM E1444 using the wet continuous method with fluorescent

particles. Follow the particular magnetic particle media manufacturer's instructions regarding

use, safety data, and disposal.

1. Follow the equipment and materials manufacturer's instructions to perform the inspection

regarding use, safety data, and disposal. Use the corresponding method of magnetization

and amperage listed in Table 72-30-1.

2. Inspect parts for the following conditions:

a. All cracks or indications of the start of cracks

b. Grinding encountered after the manufacturing process

c. Seams

d. Laps or ruptures

Unless Section 72-20 contains specific instructions to remedy unsatisfactory conditions

discovered during the inspection, discard parts which exhibit any of the conditions described in

steps 2a through 2d.

3. Look for linear indications which break into corners, edges, holes, thread roots, fillets, gear

tooth roots or keyways on parts. Identify parts which contain linear indications which cannot

be reworked.

4. Label parts which fail inspection as such; indicate reason for failure and if repair or

replacement action is required.

Summary of Contents for LTSIO-520-AE

Page 18: ...xviii February 1989 INTENTIONALLY LEFT BLANK ...

Page 34: ...1 10 10 February 1989 INTENTIONAllY LEFT BLANK ...

Page 80: ...1 30 06 February 1989 INTENTIONALLY LEFT BLANK ...

Page 81: ...CHAPTER 4 AIRWORTHINESS LIMITATIONS February 1989 4 00 01 ...

Page 82: ...4 00 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 84: ...4 00 04 February 1989 INTENTIONALLY LEFT BLANK ...

Page 86: ...5 00 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 88: ...5 00 04 February 1989 INTENTIONALLY LEFT BLANK ...

Page 90: ...5 10 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 94: ...INTENTIONALLY LEFT BLANK 5 20 04 February 1989 ...

Page 96: ...5 30 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 98: ...70 00 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 100: ...70 0 04 February 1989 INTENTIONALLY LEFT BLANK ...

Page 102: ...70 10 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 104: ...70 20 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 106: ...70 30 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 108: ...70 40 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 116: ...72 00 02 February 1989 INTENTI0 NALlY LEFT BLANK ...

Page 130: ...72 00 16 February 1989 INTENTIONALLY LEFT BLANK ...

Page 132: ...72 10 02 INTENTIONALLY LEFT BLANK ...

Page 153: ...INTENTIONALLY LEFT BLANK 72 10 23 ...

Page 171: ...INTENTIONALLY LEFT BLANK 72 10 41 ...

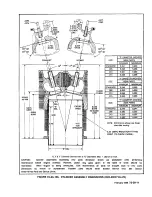

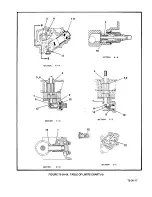

Page 173: ...7 9 10 12 11 2 81 FIGURE 72 10 15 CRANKCASE 72 10 43 ...

Page 178: ...72 10 48 INTENTIONALLY LEFT BLANK ...

Page 180: ...72 20 02 INTENTIONALLY LEFT BLANK ...

Page 196: ...72 20 18 February 1989 INTENTIONALLY LEFT BLANK ...

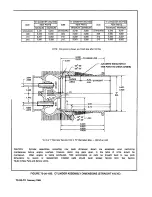

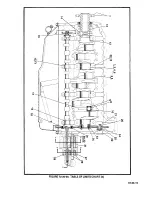

Page 211: ...FIGURE 72 30 08 TABLE OF LIMITS CHART 3 72 30 15 ...

Page 220: ...72 40 02 INTENTIONALLY LEFT BLANK ...

Page 238: ...72 40 20 INTENTIONALLY LEFT BLANK ...

Page 240: ...72 50 02 INTENTIONALLY LEFT BLANK ...

Page 258: ...72 60 02 INTENTIONALLY LEFT BLANK ...

Page 276: ...72 60 20 INTENTIONALLY LEFT BLANK ...

Page 278: ...72 70 02 INTENTIONALLY LEFT BLANK ...

Page 286: ...72 70 10 INTENTIONALLY LEFT BLANK ...

Page 288: ...72 80 02 INTENTIONALLY LEFT BLANK ...

Page 294: ...72 80 08 INTENTIONALLY LEFT BLANK ...

Page 296: ...73 00 02 INTENTIONALLY LEFT BLANK ...

Page 298: ...73 00 04 INTENTIONALLY LEFT BLANK ...

Page 304: ...73 10 06 INTENTIONALLY LEFT BLANK ...

Page 306: ...74 00 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 315: ...CHAPTER 75 AIR 75 00 00 GENERAL 75 00 01 ...

Page 316: ...75 00 02 INTENTIONALLY LEFT BLANK ...

Page 318: ...75 00 04 INTENTIONALLY LEFT BLANK ...

Page 320: ...76 00 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 322: ...76 00 04 February 1989 INTENTIONALLY LEFT BLANK ...

Page 384: ...76 00 66 February 1989 INTENTIONALLY LEFf BLANK ...

Page 386: ...77 00 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 388: ...77 00 04 February 1989 INTENTIONALLY LEFT BLANK ...

Page 402: ...78 00 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 404: ...78 00 04 February 1989 INTENTIONALLY LEFT BLANK ...

Page 406: ...78 10 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 408: ...78 20 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 410: ...79 00 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 412: ...79 00 04 February 1989 INTENTIONALLY LEFT BLANK ...

Page 414: ...79 10 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 416: ...79 20 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 418: ...80 00 02 February 1989 INTENTIONALLY LEFT BLANK ...

Page 437: ......

Page 438: ...www continentalmotors aero Continental Motors Inc ...