9. Service and maintenance

45

Change the control transformer setting as follows if

the output voltage is not correct:

•

Set the main power switch to "O" (OFF) and secure

it from being switched on again.

•

Please wait another 10 minutes. The power

condensers require this time in order to discharge!

•

Change the control transformer setting accordingly.

Fig. 24 illustrates an example.

•

Then check the setting again.

9.10

Fittings

The fittings of the air and water circuits have to be

checked and, if required, re-tightened according to the

maintenance schedule.

Check the hose and piping for unsealed areas.

9.11

General maintenance and cleaning

Important

Blow off the screw compressor unit with

compressed air at the specified intervals (never

direct compressed air towards persons) paying

particular attention to:

•

Regulating elements

•

Fittings

•

Compressor block

•

Cooler

•

Electric motor

•

Remove and clean the dirt trap strainer

(W-version only)

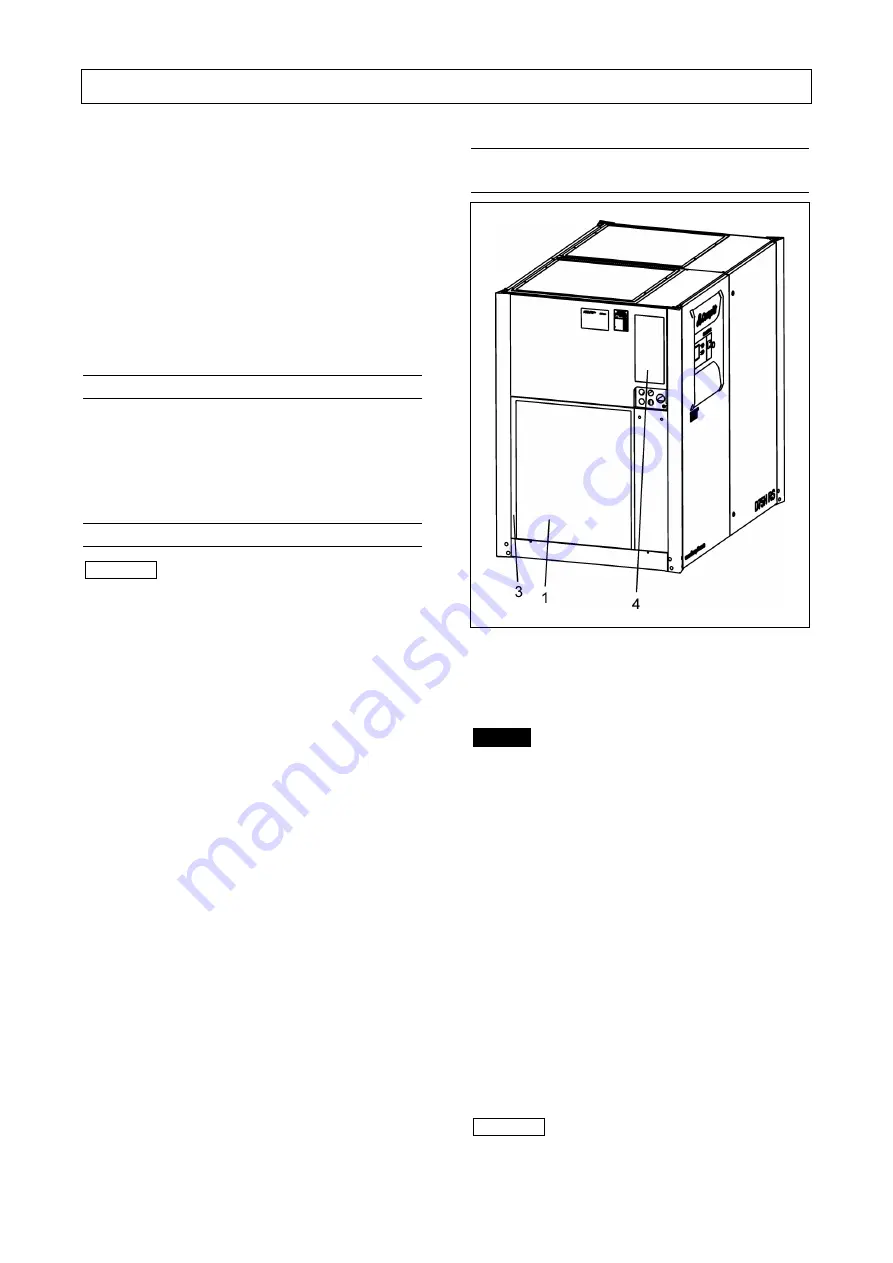

9.12

Clean / change filter with cooling air

inlet and control cabinet inlet

Fig. 25

1 Filter mat cooling air inlet

3 Sound-proofing element

4 Inlet filter

Danger

Only perform checks and carry out work on the

screw compressor when the unit is out of

operation, depressurized, and secured from being

switched on again!

a) Filter mat cooling air inlet (-1- Fig. 25)

Perform filter mat change as follows:

•

Remove fixing bolts.

•

Take out the filter mat (-1- Fig. 25) and clean it,

replace it if damaged.

•

Return the filter mat to the silencer chamber

(-3- Fig. 25).

•

Secure the filter mat using the fixing bolts.

Cleaning:

Clean the filter mat by brushing or washing.

Important

Never install the filter mat in a wet or moist state!

Summary of Contents for D110H RS

Page 2: ......

Page 58: ...11 Annex 56 11 2 Layout plan 11 2 1 Layout plan D110H RS Fig 32 all dimensions in mm...

Page 59: ...11 Annex 57 Fig 33 all dimensions in mm...

Page 61: ...11 Annex 59 Fig 35 all dimensions in mm...

Page 63: ......