CompAir UK Ltd

PUBLICATION 98407/1050

Page 8

1.4.3

GENERAL SAFETY PRECAUTIONS

•

When using cleaning solvents, local Health and Safety Regulations must be complied with. Provide good

ventilation and use suitable protection such as a breathing filter mask, safety glass, protective apron and

gloves.

•

Safety footwear should be compulsory in all workshops. Safety helmets must be worn if there is any risk

of falling objects.

•

If using compressed air for cleaning purposes, ensure safety regulations are complied with and

appropriate clothing worn.

•

Never direct compressed air onto your skin or at other people. Never use compressed air to clean loose

dirt from clothing.

•

Before releasing compressed air through a hose make sure the free end is held securely so that it cannot

whip and cause injury.

•

Avoid injury by using a hoist to lift heavy loads. Check that all chains, hooks, shackles and slings are in

good condition and are of the correct capacity. They must be tested and approved according to local

safety regulations.

•

Cables, chains or ropes should never be applied to lifting eyes. Always use an appropriate shackle or

hook, properly positioned. Arrange lifting cables so that there are no sharp bends. Use a spreader bar to

avoid side loads on hooks, eyes and shackles and never leave a heavy load unattended.

•

When a load is on a hoist stay clear of the danger area beneath and around it. Keep lifting acceleration

and speed within safe limits.

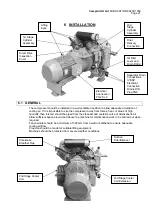

1.4.4 INSTALLATION

PRECAUTIONS

•

Competent personnel under a qualified supervisor must only carry out installation work.

•

A fused isolator switch must be fitted between the main power supply and the compressor.

•

Precautions must be taken to ensure that no injury is caused to passers-by through loose clothing being

sucked into compressor intake.

•

Ensure that the discharge pipe from the compressor to the user pipework, receiver or storage is free to

expand and that no flammable material is within the vicinity. If any such material is close-by take steps to

preclude ignition.

•

A manual shut-off valve should be fitted in the discharge line to allow the compressor to be isolated. Non

return valves cannot be relied upon for isolating parts from a pressure system. A safety valve must be

installed between any compressor unit and the isolating valve.

•

A pressure-reliving device must be fitted to every pressure vessel, or equipment containing air or gas

above atmospheric pressure. Never remove or tamper with safety devices, guards or insulation fitted. In

order to limit the risk of Legionnaires Disease, CompAir

UK LTD

advise caution with the use of cooling

towers for water cooling the compressor. Closed circuit or direct mains cooling is preferred.

•

Pipework or other parts with a surface temperature above 70°C, which may be accidentally touched in

normal operation, must be guarded or insulated. Other high temperature pipework should be clearly

marked and all pipework should be clearly marked.

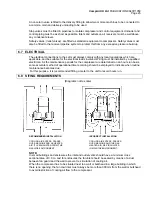

1.4.5 OPERATIONAL

PRECAUTIONS

•

Competent personnel under a qualified supervisor must only operate the compressor.

•

Do not operate compressor with any removable inspection cover removed e.g. crankcase

doors, valve

covers etc.

•

Never remove or tamper with safety devices, guards or insulation materials.

•

The compressor must only be operated at the supply voltage and frequency for which it is designed.

Always isolate power before maintenance or servicing.

•

When mains power is ON, lethal voltages are present in the electrical circuits and extreme caution is

need when essential work is carried out on the electrical system.

ALWAYS CONSULT A QUALIFIED

ELECTRICIAN BEFORE ANY SUCH

ESSENTIAL WORK.

Summary of Contents for 5211.2.IA

Page 2: ......

Page 14: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 12...

Page 16: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 14 REMARKS DATE REMARKS DATE...

Page 22: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 20...

Page 32: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 30...

Page 38: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 36...

Page 61: ......