HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

12

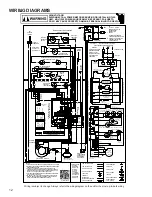

WIRING DIAGRAMS

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

GND

JU

N

C

T

IO

N

B

O

X

WH

BK

GR

G ND

G ND

P RE SS .

S W ITC H

F RONT CO VE R

NO

(8)

C

PRESSURE SWITCH

FRONT COVER

NO

GY

GY

C

(O N SO ME M O DELS)

IN DUCT O R CO IL

O PT IO NA L

O PT IO NA L

T R (9)

LIM IT CO NTRO LS

M ANUA L RE SET RO LLO UT

P RES S. SW IT CH

LO W FIRE

P RES S.

LIM IT CO N TRO L

AU TO RE SE T PR IM ARY

AUT O RE SET A UXILIA RY LIMIT

24 VA C

T O +VD C

TR (5)

F US E 3A

40 V A

HO T S URFAC E

3Ø ID

IN

T

E

G

R

A

T

E

D

CO

NT

RO

L

M

O

DULE

A IR CLE ANER

POLARIZED AND

MUST BEPROPERLY

WIRING TO UNIT

BEFORE SERVICING

DISCONNECT POWER

OVERCURRENT PROTECTIONDEVICE

Ø /60 HZ POWERSUPPLY WITH

TO 115VAC/1

SWITCH ASSEMBLY

ID BLOWERMODULATING PRESS

URE

SWITCH

LOW FIRE

(HONEY WELL)

GAS VALVE

2 CIRCUIT

(SINGLE CONTROLON 40 kBTU)

MANUAL RESET ROLLOUT LIMIT CONTROLS

LIMIT CONTROL

AUTO RESET PRIMARY

BURNER COMPARTMENT

BLOWERCOMPARTMENT

AUTO RESET

LIMIT CONTROL

F

U

R

N

A

C

E

C

O

N

T

R

OL

M

O

DUL

E

M

O

DU

L

AT

ING

INT

E

RG

R

A

T

E

D

CO

O

L

T

A

P

S

H

EAT

T

A

PS

FA

N

TA

P

S

DI

P

S

W

IT

CHE

S

HE

A

T

O

F

F

H

EAT

S

ET

U

P

CO

O

L

S

E

T

UP

P

U

LL U

P

PU

L

L

D

O

W

N

24 V THERMOSTAT CONNECTIONS

24V

HU

M

.

IN

T

E

G

R

A

T

E

D C

O

NT

RO

L

M

O

DULE

2

4

V

T

H

ER

M

O

ST

A

T

CO

NNE

CT

IO

NS

(OPENWHEN

DOOR SWITCH

24 V 3A

ECM MTR

WHILE IN STANDBY(NO THERMOSTAT INPUTS)

RECENT, DEPRESSSWITCH FOR MORETHAN 2 SECONDS

5. TO RECALL THELAST 10 FAULTS, MOST RECENT TO LEAST

N.E.C.ANDLOCALCODES.

4. UNIT MUST BEPERMANENTLY GROUNDEDANDCONFORM TO

LEAST 105°C. USECOPPERCONDUCTORSONLY.

WIRING MATERIAL HAVING A TEMPERA

TURE RATING OF AT

FURNACEMUST BEREPLACED, IT MUST BEREPLACEDWITH

3. IF ANY OF THE ORIGINAL WIREASSUPPLIED WITH THE

USEDWHEN SERVICING.

2. MANUFACTURER'S SPECIFIEDREPLACEMENT PARTS MUST BE

1. SET HEAT ANTICIPATOR ON ROOM THERMOSTAT AT 0.7AMPS.

PLUG CONNECTION

INTEGRATED CONTROL

INTERNAL TO

HI VOLTAGE FIELD

HI VOLTAGE (115V)

LOW VOLTAGE (24V)

LOW VOLTAGE FIELD

PROT. DEVICE

SWITCHPRESSURE

SWITCH (TEMP)

FIELD SPLICE

EQUIPMENT GND

PROPERLY POLARIZED

TO UNIT MUST BE

WIRING.TO UNIT MUST BE

POWER BEFORE SERVICING

POWERSUPPLY WITH

115 VAC/1

HZ

Ø /60

TO

MIC RO

T O

R

G ND (4)

+ VD C (1)

RX (2)

T X (3)

INDO O R

AIR

C IRCULA TO R

B LW R

RD GY

BL

BK

GND

PROTECTION

DEVICE

LINE

RD

TO

C

BK

RD

IGNITER

OR

TERMINAL

PM

HARNESS

NO

(12)

3

CIRCULAT O R

BK

OVERCURRENT

0140F02005-A

IG NIT ER

24

PM

INDUCED

DRAFT

BLOWER

EA C

C

INDUCTOR COIL

PU

YL

DE HU M

GND

2

HOT

SURFACE

IGNITER

(7)

NEUT RAL

DO O R

SW ITCH

4

3

2

CH

ASSI

S

GROU

N

D

VAC

GND

YL

CONNECTOR

HUM

OVERCURRENT

(6)

C

MODULATING

DISCONNECT

HIG H FIRE

INDO O R

H UM IDIFIE R

N

1

CO NT RO LS

OR

JUNCTION

B LW R

CIRCULATOR BLOWER

R

1

GND

JUN CTI O N B O X

NEUTRAL

BLOWER

COMPARTMENT

DOOR OPEN)

C

LINE

BK

4

N EUTRA L

C

F S

2

DISCONNECT

PU

HIGHFIRE

PRESSURE

SWITCH

W1

NO

O

WH

5

G ND (4)

BK

3

IG N

PK

(3)

NOTES:

PU

L

AIR

WH

Y1

ELECT RO NIC

Y2

OR

NEUT RA L

1

(11)

WH

SW ITCH

NO

WH

TRA NS FO RME R

BR

BL

GR

2

GROUNDED.

W2

WARNING:

FIELD GND

WH

115

NEU TRA L

B LW R

1

ANDGROUNDED.

RD

G A S

VA LVE

PU

(O N SO M E MO DE LS )

C

1

VAC

G

C

GR

FLAME

SENSOR

(2)

PRESSURE

1

L

BR

3

NO

N

OR

T O

MICRO

WARNING:DISCONNECT

PK

AUXILIARY

2

BL

GY

BK

RD

OR

BR

BK

WH

RD

OR

WH

WH

WH

WH

BK

YL

OR

BI

AS

2

FUSE

AD

JU

S

T

LI

N

E

DE

H

U

M

2

3

1

NE

UT

RA

L

3

DE

LA

Y

1

FL

A

M

E

SEN

S

O

R

4

DIAGNOSTIC

LED'S

O

G

ID

B

L

O

W

E

R

CO

N

N

E

CT

O

R

Y2

HUM

EAC

W1

R

2

Y1

1

C

W2

DE

H

UM

10

6

3

45

2

7

11

1

12

8

9

HSI

AUX

OR

2

G ND

(10)

OR

BK

BR

40 V

A

T

R

ANSF

O

R

M

E

R

GY

RA

M

P

IN

G

BL

GY

INT EG R AT ED CO N TRO L

MO DULE

FLAME

S ENS O R

115

VAC

BK BLACK

PUPURPLE

YL YELLOW

BL BLUE

WH WHITE

BRBROWN

PK PINK

COLOR CODES:

ORORANGE

GY GRAY

RD RED

GR GREEN