EXEMPTIONS TO MANUFACTURER'S LIABILITY AND WARNINGS

The manufacturer is to be considered exempt from any liability in the case where the

warnings are not observed below:

-

THE OPENING OF THE TANK AND ANY RELATED MAINTENANCE CAN ONLY BE UNDERTAKEN

AFTER HAVING VERIFIED THAT THE PRESSURE OF THE TANK IS ZERO. THE NEEDLE OF THE

PRESSURE GAUGE MUST INDICATE “0” BAR (TANK DISCHARGED). HOWEVER, BEFORE ANY

OPERATION, SET TO ZERO THE INTERNAL PRESSURE OF THE TANK TO DISCHARGE ANY

RESIDUAL AIR INSIDE OF THE TANK. OPEN THE BALL VALVE OF THE NEBULIZER (PART 5) OR

THE VENT VALVE OF THE FOAM NEBULIZER (PART 20)

-

DO NOT UNSCREW THE REFILL CAP WITH YOUR FACE DIRECTLY IN FRONT OF IT.

-

THIS CAP CONTAINS A SAFETY HOLE THAT ALLOWS THE SAFE RELEASE OF PRESSURE.

THEREFORE IF DURING THE OPERATION OF OPENING THE CAP A RELEASE OF AIR IS DETECTED

FROM THE AFOREMENTIONED HOLE, IMMEDIATELY STOP UNSCREWING THE CAP AND WAIT

FOR THE AIR TO BE EXPELLED.

-

THE PRESSURE OF COMPRESSED AIR LOADED MUST NOT BE GREATER THAN 6 BAR

-

THE NEBULIZER/FOAM NEBULIZER MUST ONLY BE USED BY QUALIFIED ADULTS (AFTER

CAREFUL READING OF ALL OF THE INSTRUCTIONS FOR USE)

-

WHILE USING THE NEBULIZER/FOAM NEBULIZER THE OPERATOR MUST FOLLOW ADEQUATE

SAFETY MEASURES (WEARING MASK, SAFETY GOGGLES, GLOVES) ;

-

THE NEBULIZER/FOAM NEBULIZER MUST NOT BE USED FOR THE CLEANING OF ANIMALS,

ELECTRIC MOTORS, AND HOT SURFACES;

-

THE NEBULIZER/FOAM NEBULIZER HAS BEEN DESIGNED AND CONSTRUCTED FOR THE USE OF

WATER, NEUTRAL DETERGENT SOLUTIONS (PH=5) THAT ARE NON AGGRESSIVE NOR

CORROSIVE;

-

IT IS ABSOLUTELY FORBIDDEN TO USE FLAMMABLE LIQUIDS (ALCOHOL, SOLVENTS, PETROL,

ETC,), COMBUSTABLES (OXYGEN) OR FLAMMABLE GASES WITH THIS MACHINE. DANGER OF

EXPLOSION;

-

IT IS ABSOLUTELY FORBIDDEN TO USE DETERGENTS OR SIMILAR PRODUCTS THAT ARE NOT

PH=5;

-

THE NEBULIZER/FOAM NEBULIZER MUST ONLY BE MOVED BY USING THE APPROPRIATE

HANDLE;

-

ANY MAINTENANCE MUST BE ONLY BE CARRIED OUT BY A QUALIFIED TECHNICIAN;

-

AFTER USE, TO AVOID CORROSION EMPTY COMPLETELY THE TANK, WASH WITH CLEAN

DRINKING WATER AND TURN UPSIDE DOWN TO DRY;

-

CHECK PERIODICALLY THE EFFICIENCY AND THE GOOD RUNNING OF THE NEBULIZER/FOAM

NEBULIZER, IN PARTICULAR THE PRESSURE GAUGE AND THE SAFETY VALVE AND WHEN

NECESSARY REPLACING THEM WITH ORIGINAL SPARE PARTS;

-

IT IS FORBIDDEN TO WELD TO THE TANK ANY COMPONENT BY ANY METHOD OF WELDING;

-

IT IS ABSOLUTELY FORBIDDEN TO PUNCTURE AND/OR SCREW TO THE TANK ANY

COMPONENTS;

-

THE TANK WAS NOT DESIGNED OR CONSTRUCTED TO WITHSTAND IMPACTS OUTSIDE OF THE

NORMAL OPERATION OF THE MACHINE AND THEREFORE ANY SUCH IMPACTS OR SHOCKS MUST

BE AVOIDED. IF DURING THE LIFE OF THE MACHINE DEFORMATIONS IN THE METAL IN

CRITICAL AREAS ARE DISCOVERED DUE TO IMPACTS OR SHOCKS IT IS OBLIGATORY TO

REPLACE THE TANK IMMEDIATELY,

-

USE THE TANK SOLELY WITHIN THE PRESSURE AND TEMPERATURE LIMITS INDICATED ON THE

LABELS OF THE TANK AND IN THE CERTIFICATE OF CONFORMITY

-

THE MANUFACTURER DOES NOT ASSUME ANY RESPONSIBILITY FOR ANY TAMPERING WITH THE

MACHINE BY A THIRD PARTY;

-

FOR CORRECT MAINTENANCE ALWAYS USE ORIGINAL SPARE PARTS OF THE MANUFACTURER.

15

Summary of Contents for SP 24 FOAM

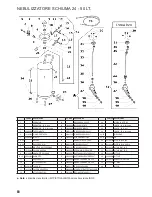

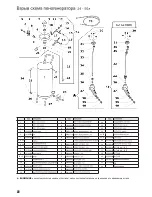

Page 22: ...23 23 24 24 24 26 26 28 29 30 31 25 22...

Page 23: ...CE PED 23...

Page 24: ...ph 5 24 50 6 5 C 50 C 24 24 50 6 5 C 50 C...

Page 25: ...0 5 20 H 7 PH 7 25...

Page 26: ...24 50 24 50 2 2 4 2 6 5 10 6 5 8 19 1 2 1 2 3 1 1 10 5 14 2 9 20 26...

Page 27: ...40 cm 1 14 5 6 10 2 2 4 2 6 7 14 36 1 1 2 9 17 27...

Page 31: ...12 Idrobase S r l Comet 31...