Reflect-O-Ray

®

EDS-4DI & EHS-4DI

Installation, Operation & Service

Page 18

Combustion Research Corporation

GAS SUPPLY

In industrial installations where the natural gas pressure at

the meter is available at higher pressure than the standard

7" TO 14" W.C., it may be possible to cut down on gas

piping costs (when local codes and the Fire Marshal

approve) by running high pressure gas lines inside the

building or on the outside of the building. In no case should

the pressure exceed 10% of the service supply pressure.

When using a high pressure gas distribution system each

heating zone should be equipped with a pounds to inches

service regulator with soft seat, positive 100% lock-up.

Allowing high gas pressure on the downstream side of the

regulator will damage the control valve in the gas train. The

outlet pressure of the service regulators should be set at 7"

W.C. for natural gas and 11" W.C. for LP gases/propane

gases. If it is not practical to regulate in "zones", each

burner may be equipped with its own regulator.

To meet the requirements of 100% positive lock-up and

internal relief vent must be piped to the outside of the

building. It is recommended that an intermediate service

regulator, such as a Maxitrol 325 Series or approved equal

be used.

The typical discharge pressure on the down stream side of

the gas meter furnished by the gas company is usually 5

P.S.I.G. while the discharge pressure of the regulator on

the propane tank is usually set at 15 P.S.I.G.

Proper sizing of low and high pressure piping distribution

systems for natural gas should be made in accordance

with the National Fuel Gas Code, ANSI Z223.1 (current

standard) NFPA No. 54. Consult the supplier of the

propane tank and vaporizing system for the sizing of the

piping system for LP gas pipe work.

When leak testing the gas piping system, the Reflect-O-

Ray

®

burners must be isolated from the gas piping

system. High-pressure compressed air used in the leak

test will damage the control valve in the burner gas train,

which will result in unsafe operation of the burner(s). For

proper and safe test procedures, observe the provisions of

Part #4, of the National Fuel Gas Code, ANSI Z223.1

(current standard) -

Inspection, Testing and Purging

or

refer to equivalent local for the United States. In Canadian

see gas code CAN/CGA-B149.1& CAN/CGA-B149.2.

NOTE: It is important that the entire system, up to the

burner gas connection, be checked for leaks, prior to start

up.

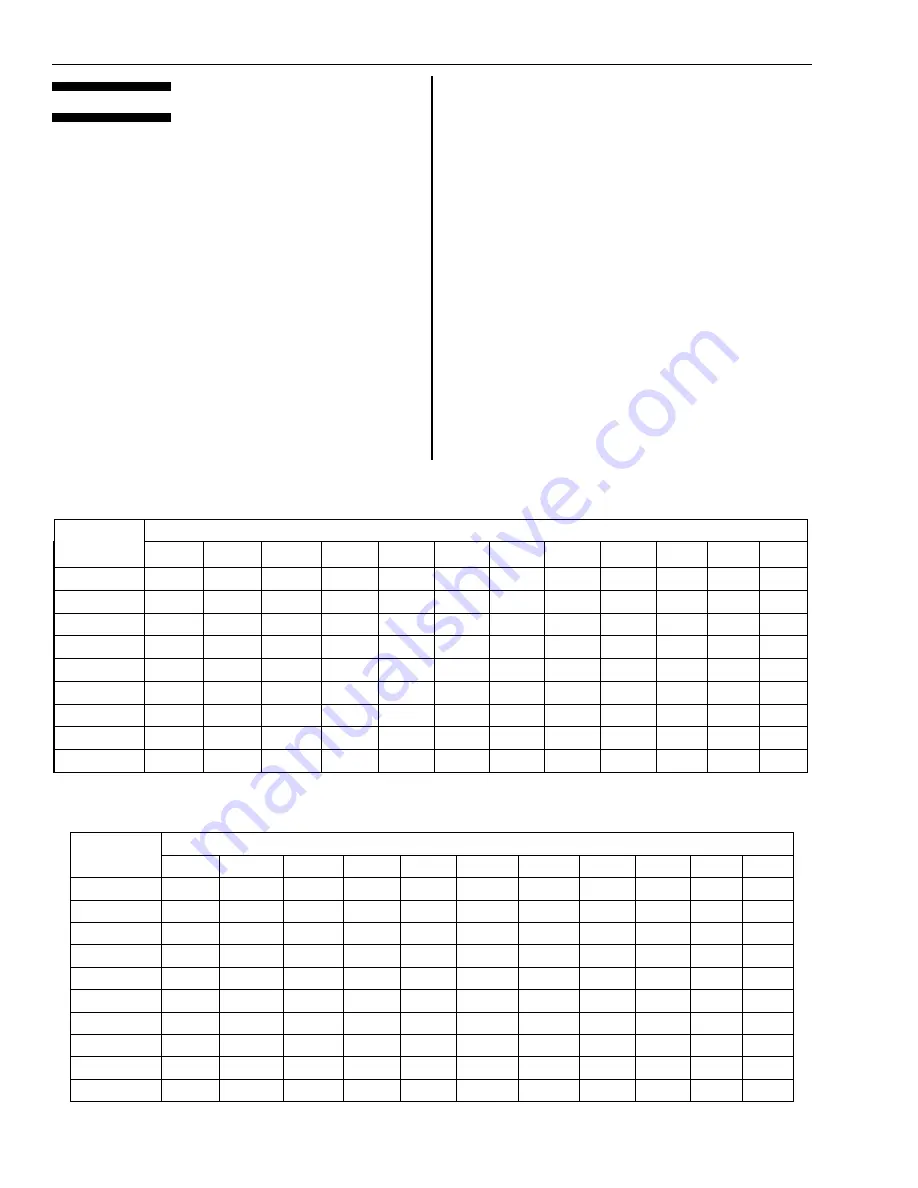

TABLE

MAXIMUM CAPACITY OF PIPE IN CUBIC FEET OF GAS PER HOUR

(Pressure Drop of 0.5 Inch Water Column and 0.6 Specific Gravity Natural Gas )

TOTAL EQUIVALENT LENGTH OF PIPE (FEET)

PIPE SIZE OF

STANDARD

SCH. 40 PIPE

10 20 30 40 50 75

100

125

150

175

200

250

1/2 120

85

70

60

54

44

38

34

31

29

27

24

3/4

272 193 157 136 115 99 82 76 67 65 58 52

1 545

385

315

272

244

198

173

154

141

130

122

109

1-1/4 1,201

848 693 600

537

439

380

340

310

287

268

240

1-1/2 1,862

1,316

1,074

931 832 680 588 527 480 445 416

372

2 3,766

2,663

2,174

1,884 1,680 1,373 1,190 1,065 971 900 841 753

2-1/2 6,165

4,358

3,559

3,082 2,752 2,254 1,950 1,743 1,593 1,473 1,379 1,233

3 10,502

7,426

6,063

5,250 5,015 3,841 3,549 3,106 2,895 2,682 2,508 2,242

4 22,031

15,577

12,718

11,015

10,510

8,158 7,430 6,548 6,060 5,066 5,250 4,700

TABLE

MAXIMUM CAPACITY OF PIPE IN CUBIC FEET OF GAS PER HOUR

(Available Pressure 5 P.S.I.G. 10% Pressure Drop and 0.6 Specific Gravity Natural Gas)

TOTAL EQUIVALENT LENGTH OF PIPE (FEET)

PIPE SIZE OF

STANDARD

SCH. 40 PIPE

50 100 150 200 250 300 400 500

1,000

1,500

2,000

1 1,863

1,320

1,074

931

832

760

658

584

416

341

293

1-1/4 3,880

2,744

2,240 1,938 1,732 1,580 1,370 1,218 866 708 609

1-1/2 5,860

4,140

3,375 2,920 2,620 2,384 2,065 1,835 1,310 1,070 918

2 11,360

8,060

6,560

5,680 5,080 4,640 4,025 3,570 2,540 2,080 1,792

2-1/2 18,280

12,933

10,540 9,140 8,180 7,460 6,460 5,740 4,090 3,390

2,875

3 32,620

23,100

18,800

16,300 14,500

13,310 11,520 10,250

7,290 5,960 5,125

4 67,400

47,600

38,840

33,650 30,160

27,550 23,800 21,140

15,080 12,330 10,620

5 122,900

86,900

71,000

61,400 55,000

50,200 43,450 38,600

27,500 22,570 19,400

6 201,000

142,700

115,000

100,300 89,800

82,100 71,800 63,000

44,900 36,700 31,590

8 418,000

295,000

240,800

208,500 186,800 170,800 148,000 131,200 93,400 73,400 65,600