19

MACHINE PREPARATION

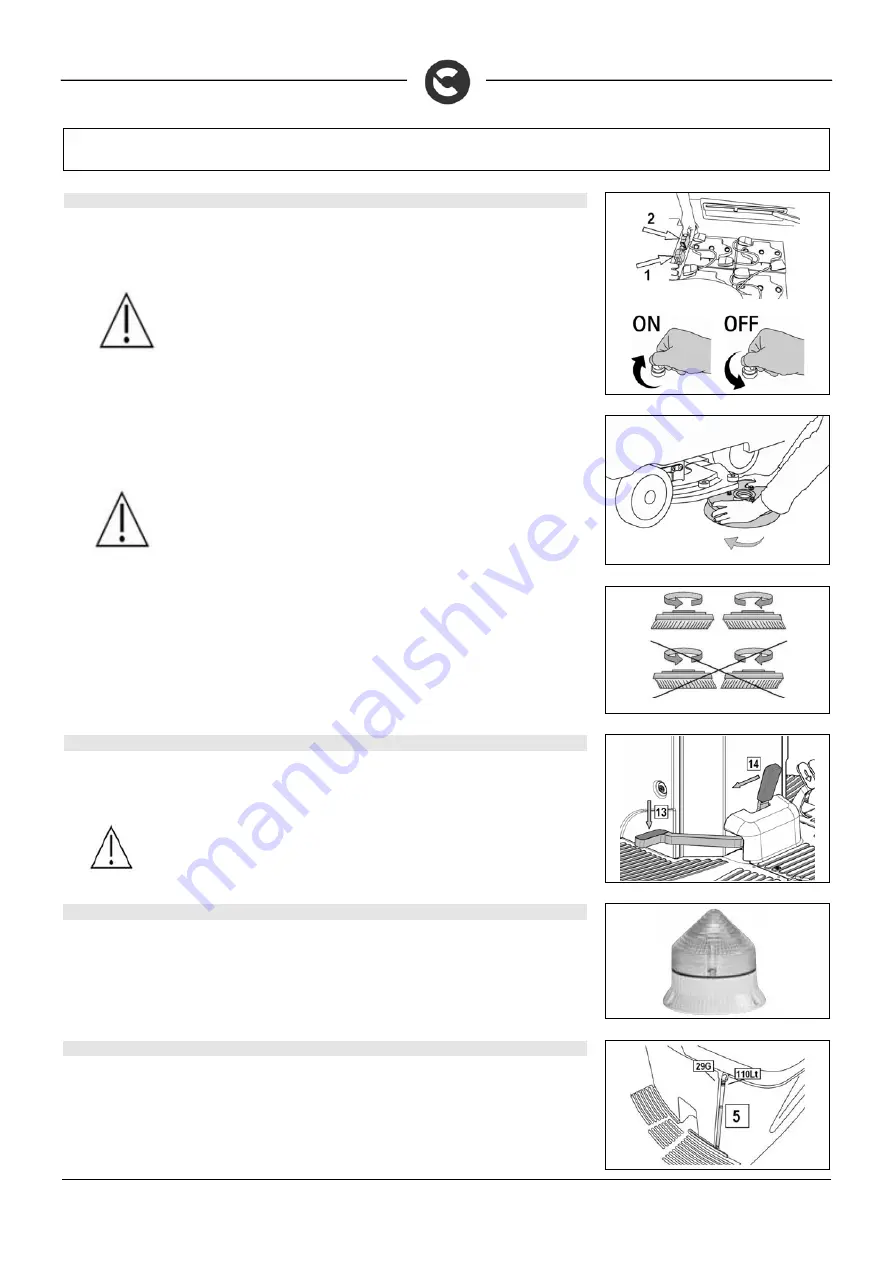

28.

DISC BRUSH ASSEMBLY

1.

Make sure the parking brake is engaged and that the main switch is OFF

2.

Connect the battery connector

3.

Turn the key to the "ON/I" position. The base raises automatically.

4.

Turn the key to the “OFF/0” position and remove it from the electrical board.

WARNING: during this operation, verify that there are no people or objects near

the brush.

5.

With the base up, insert the brushes in the plate housing beneath the base, turning them until

the three pins enter the niches in the plate itself; turn until the pin is pushed towards the coupling

spring and is locked into place. The photo shows the rotation direction to hook up the right-hand

brush; for the left-hand one, rotate in the opposite direction.

ATTENTION: You are advised to always wear protective gloves, to avoid the risk

of serious injury to your hands.

You are advised to invert the right and left-hand brushes every day. If the brushes are not new however,

and have deformed bristles, it is better to reassemble them in the same position (the right-hand one on

the right, and the left-hand one on the left), to prevent the different inclination of the bristles producing an

overload on the brush motor as well as excessive vibrations.

29.

SERVICE BRAKE AND PARKING BRAKE

The machine has an electronic braking system. To brake, in normal conditions, just remove your foot from

the accelerator pedal. If this service brake is working badly, or if necessary, activate the brake pedal (13)

pushing it downwards. To engage the parking brake, press the brake pedal (13) and lock it by pulling the

lever (14) to the left. The red indicator light on the instrument panel will switch on.

WARNING: to avoid any damage to the machine, always disengage the parking brake

before beginning to work or before making any transfer manoeuvres

30.

BLINKING LIGHT (OPTIONAL)

The machine can be equipped with a blinking light that turns on automatically when the key in the main

switch is turned on.

31.

EMPTY SOLUTION TANK DEVICE

To check the quantity of water in the solution tank there is a special level indicator tube (5) next to the

driver's seat.