ROUTINE JACK

MAINTENANCE BULLETIN

1 OF 1

To ensure proper operation of all aircraft hydraulic jacks, it is important that at a minimum,

each jack is certified on an annual basis. The following procedure is provided as an aid

to the certification process.

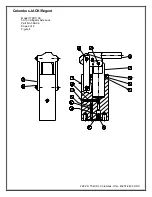

1) With no external load applied to the jack, fully close release valve and fully

extend ram(s) to verify function and the absence of external hydraulic

leakage.

2) Open release valve and verify ram(s) retract fully.

3) Position jack under jack tester.

4) Close release valve, and fully extend all ram(s). Open release valve:

a) Single Stage Cylinder - Lower ram 2-4 inches.

b) Multi-Stage Cylinder - Lower smallest ram

only

approximately

one inch.

5) Pressurize the jack against the jack tester. Using a calibrated pressure

gauge on either the jack or the jack tester, monitor the pressure until the

capacity (operating pressure) of the jack is reached.

6) With the jack pressurized against the jack tester, hold in this position for

3 minutes. Verify that the jack pressure has not decreased, indicating

internal leakage.

7) Open the release valve to relieve jack pressure against the jack tester.

8) Set the safety relief valve per jack operation and maintenance manual.

2222 S. Third St., Columbus, OH 43207 - Tel: 614 443 7492 - Fax 614 444 9337 - email: [email protected] - www.columbusjack.com

West Coast Office: 369 Cliffwood Park St. Unit D, Brea, CA 92821 - Tel: 714 257 9412 - Fax 714 257 9385

TO PROVIDE COMPLETE INFORMATION ON SERVICING

ColumbusJACK/REGENT QUALITY GROUND HANDLING EQUIPMENT

RECOMMENDED ANNUAL JACK CERTIFICATION PROCEDURE

RJM 147