Page 2 of 8

Carefully remove the unit from its packaging and place it on a flat surface. Examine the unit for transit damage. If damage is found, return the

product to your local dealer for warranty replacement. Do not use damaged or broken parts.

Before attempting to connect the unit’s wiring harness, refer to the wiring diagram in FIGURE 3. The wiring diagram describes the function for

each wire.

Notes:

1. Larger wires and tight connections will provide longer service life for components. For high current wires it is highly recommended

that terminal blocks or soldered connections be used with shrink tubing to protect the connections. Do not use insulation displacement

connectors (e.g., 3M Scotchlock type connectors).

2. Route wiring using grommets and sealant when passing through compartment walls. Minimize the number of splices to reduce voltage

drop. All wiring should conform to the minimum wire size and other recommendations of the manufacturer and be protected from moving

parts and hot surfaces. Looms, grommets, cable ties, and similar installation hardware should be used to anchor and protect all wiring.

3.

Fuses or circuit breakers should be located as close to the power takeoff points as possible and properly sized to protect the wiring and

devices.

4. Particular attention should be paid to the location and method of making electrical connections and splices to protect these points from

corrosion and loss of conductivity.

5. Ground termination should only be made to substantial chassis components, preferably directly to the vehicle battery.

6. Circuit breakers are very sensitive to high temperatures and will “false trip” when mounted in hot environments or operated close to their

capacity.

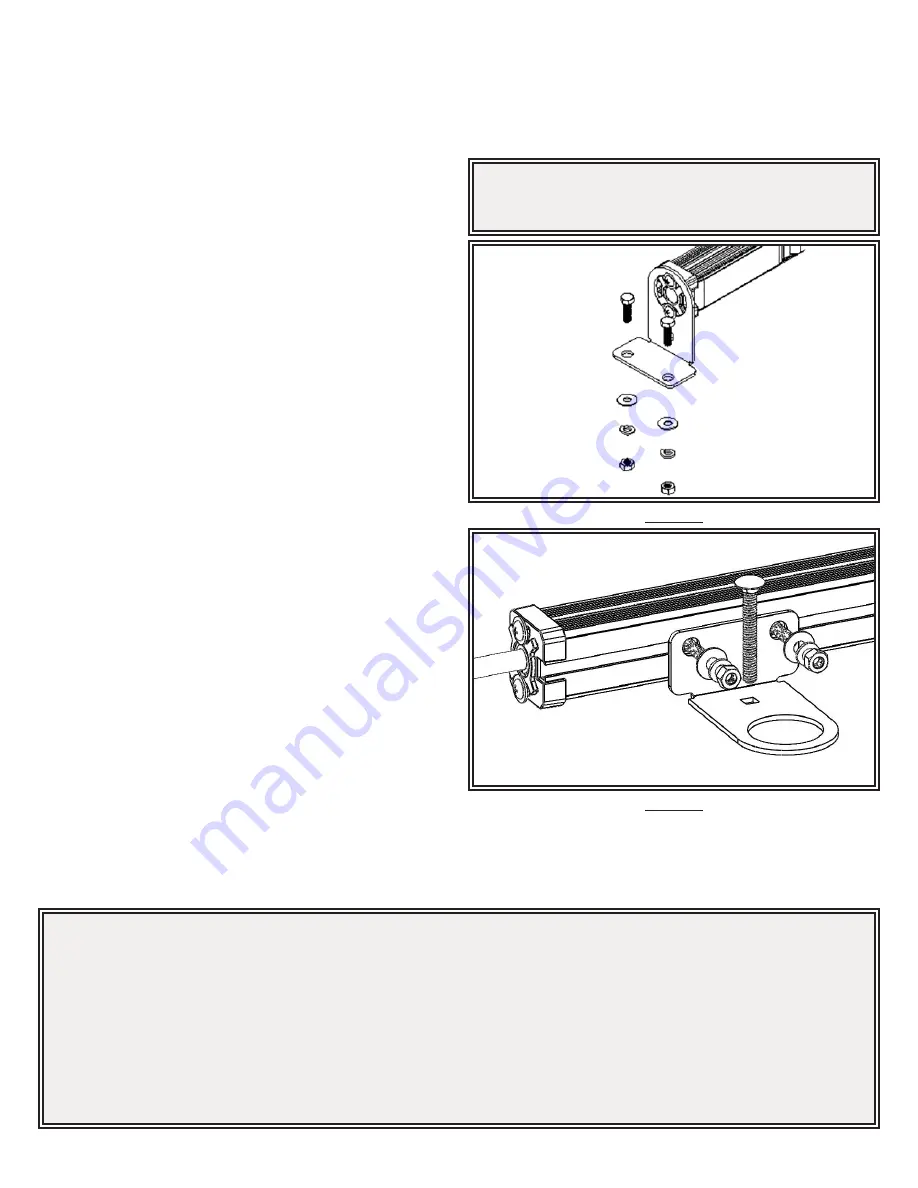

Figure 1

Unpacking:

Wiring Instructions:

The mounting location should be chosen such that there is maximum

visibility to the oncoming traffic.

Installation and Mounting:

CAUTION!

When drilling into any vehicle surface, make sure that the area is

free from any electrical wires, fuel lines, vehicle upholstery, etc.

that could be damaged.

End Bracket Mounting:

Step 1.

Loosely assemble a mounting bracket to each end of the

unit as shown in FIGURE 1 using the included hardware.

Step 2.

Position the lightbar in the desired mounting location on the

rear of the vehicle with the cable exit to the driver’s side. Mark and

drill two holes for each bracket using 6.6 mm sized drill bit. The holes

are spaced 1.83” apart center to center.

Step 3.

Secure the brackets in place on the vehicle using the

supplied M6 x 1.0 mm hardware. Tilt the face of the unit to an angle

that optimizes visibility to oncoming traffic and tighten the two screws

in each end.

Figure 2

Rear Bracket Mounting:

Step 1.

Loosely assemble the mounting brackets into the rear

channel as shown in FIGURE 2 using the included hardware. Note:

Carriage bolt is customer supplied, use of a stainless steel carriage

bolt is advised to prevent corrosion.

Step 2.

Position the lightbar in the desired mounting location on the

rear of the vehicle with the cable exit to the driver’s side. Mark and

drill a hole to mount each bracket using 17/64” sized drill bit. The

brackets should be spaced a minimum of 1/2 the total length apart,

i.e., 24” apart on a 48” long product.

Step 3.

Secure the brackets in place on the vehicle using customer

supplied 1/4” thread size carriage bolts and associated hardware.

Tighten the nuts holding the brackets to the product.

Summary of Contents for Mega thin Stik Series

Page 6: ...Page 6 of 8 Notes...

Page 7: ...Page 7 of 8 Notes...