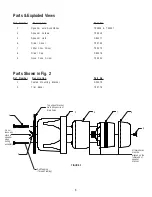

FIGURE 1

7.00"

6.25"

NOTE : All of the information listed in this booklet

must be given to the end user by the installer.

1 ) Cut a hole in the desired mounting location to

the dimensions shown in Figure 1. Make sure

this hole is properly oriented to a structural

member of the vehicle for a secure mounting.

This installation may require the use of spac-

ers or longer mounting screws to bring the

product to the desired orientation with the

exterior surface. In some installations it may

be necessary to fabricate a special adaptor

plate to achieve the desired position on the

vehicle.

2 ) Hold speaker assemblies against the bumper

and inscribe locations for drilling holes for the

mounting screws.

4

3 ) At the inscribed positions, drill holes for the

provided 1/4" x 2-1/2" screws using a 9/32"

drill bit.

4 ) Attach the speaker assemblies and bezel to

the vehicle using the fasteners shown in

Figure 2. Make sure that the siren wires are

clear of the mounting bracket to avoid dam-

age during installation. In addition, DO NOT

TIGHTEN the mounting screws completely

until the speaker is parallel and evenly

positioned with the holes on the vehicles

exterior.

5 ) Connect the wires from the speaker assem-

bly to the leads coming from the siren control

h e a d .

NOTE: When two or more speakers are to

be operated by the same control head, the

speakers must be connected in phase. In

order to accomplish this, the white wires,

which are connected to the number 1 termi-

nals on the siren drivers, must be connected

together to the same output terminal on the

siren amplifier. Likewise, the blue wires,

which are connected to the number 2 termi-

nals on the drivers, must be connected

together on the other output terminal of the

siren amplifier.

FIGURE 2

Cleaning

Clean with soap and water to remove all salt, dirt or mud. Do not use any abrasive cleaners or harsh chemi-

cals because the protective coating on the aluminum may be damaged allowing the exposed aluminum to dull

in appearance or corrode.

Maintenance

Maintenance of your FM100C and FM100V involves the cleaning of the unit and in some cases the replace-

ment of the siren driver, if required.

2

1

Summary of Contents for FM100C

Page 7: ...NOTES ...