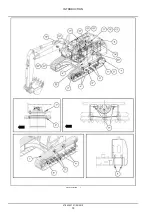

INTRODUCTION

Foreword - Important notice regarding equipment servicing

All repair and maintenance work listed in this manual must be carried out only by qualified dealership personnel,

strictly complying with the instructions given, and using, whenever possible, the special tools.

Anyone who performs repair and maintenance operations without complying with the procedures provided herein

shall be responsible for any subsequent damages.

The manufacturer and all the organizations of its distribution chain, including - without limitation - national, regional, or

local dealers, reject any responsibility for damages caused by parts and/or components not approved by the manu-

facturer, including those used for the servicing or repair of the product manufactured or marketed by the manufacturer.

In any case, no warranty is given or attributed on the product manufactured or marketed by the manufacturer in case

of damages caused by parts and/or components not approved by the manufacturer.

The manufacturer reserves the right to make improvements in design and changes in specifications at any time without

notice and without incurring any obligation to install them on units previously sold. Specifications, descriptions, and

illustrative material herein are as accurate as known at time of publication but are subject to change without notice.

In case of questions, refer to your CASE CONSTRUCTION Sales and Service Networks.

47843027 21/05/2015

3