2

P/N 192044557 REV AA

September 2017

1-1. GENERAL INFORMATION

The CM Hurricane 360 O&M Manual (P/N 656) and this supplement

provide information for the safe operation and maintenance of

this hoist. All persons operating or maintaining these hoists

should be familiar with the information contained herein and

in the O&M manual. Adherence to the precautions, procedures,

and maintenance practices described should ensure long

reliable operation.

To safeguard against the possibility of personal injury or property

damage, follow the recommendations and instructions of this

manual. This manual contains important information for the correct

installation, operation, and maintenance of this equipment. All

persons involved in the installation, operation, and maintenance of

this equipment should be thoroughly familiar with the contents of this

manual. Keep this manual for reference and further use.

Using “Commercial” or other manufacturer’s parts to repair

the CM Hoists may cause load loss.

To avoid personal injury:

Use only CM supplied replacement parts. Parts may look alike but

CM parts are made of specific materials or processed to achieve

specific properties.

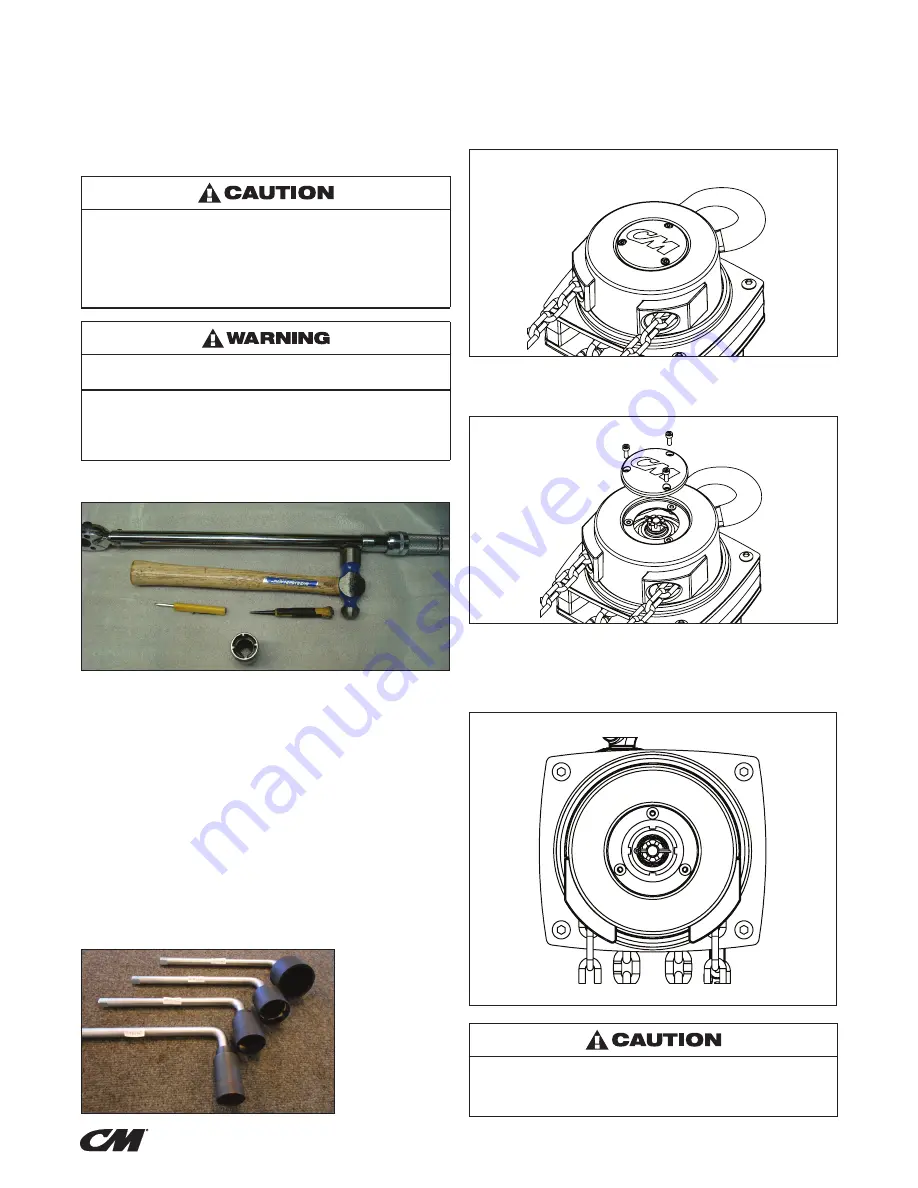

FIGURE 1: TOOLS REQUIRED

1. Hammer

2. Punch

3. Small flat screwdriver

4. Torque wrench

5. Socket to fit adjusting ring

6. Vise to secure load limiter

7. Special Sockets for adjusting load limiters

P/N 00401421 — Adjustment Tool 0.5T

P/N 00401422 — Adjustment Tool 1T

P/N 00401423 — Adjustment Tool 2T

P/N 00401424 — Adjustment Tool 3-10T

FIGURE 2: SPECIAL SOCKETS

NOTICE

To ensure proper function of the hoist load limiter systems,

perform the following steps:

STEP 1:

Remove the hoist from the supporting structure and lay it

on a flat working surface with the handwheel facing up.

Columbus McKinnon

Industrial Products GmbH

Yale-Allee 30

42329 Wuppertal / Germany

Modeled:

Drawn:

Approved:

Design Authority:

Original project:

Original scale:

1:3

Material:

General Tolerances

ISO 2768-mk

Dimensional Units

mm

Description:

Number:

Sheet

1

1

Format

F

E

D

C

B

A

1

2

3

4

A4

Columbus McKinnon

Industrial Products GmbH

Wuppertal / Germany

Columbus McKinnon Industrial Products GmbH claims proprietary r

ights in the material disclosed hereon. This drawing and/or tec

hnical information is issued in confidence

for engineering information only and may not be reproduced or u

sed to manufacture anything shown or referred to hereon without

direct permission

from Yale to the user. This drawing and/or technical informatio

n is loaned for mutual assistance and is subject to recall by Y

ale at any time.

This drawing and/or technical information is the property of Ya

le.

NOTICE TO PERSONS RECEIVING THIS DRAWING AND/OR TECHNICAL INFOR

MATION

ECN

Rev. Description of change

Date

By

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

04/08/2008

04/08/2008

Velbert

kon3

kon3

Hurricane III 1,0/1

Hand chain hoist 1000/1

Flaschenzug 1000/1 - VG

84700017

kon6

04/14/2010

Standard:

Material No:

Specified Tolerances

ISO 8015

Edges According to

DIN 6784

First Angle Projection

STEP 2:

Remove the three screws securing the plastic center cap

and remove the cap from the handwheel cover.

Columbus McKinnon

Industrial Products GmbH

Yale-Allee 30

42329 Wuppertal / Germany

Modeled:

Drawn:

Approved:

Design Authority:

Original project:

Original scale:

1:3

Material:

General Tolerances

ISO 2768-mk

Dimensional Units

mm

Description:

Number:

Sheet

1

1

Format

F

E

D

C

B

A

1

2

3

4

A4

Columbus McKinnon

Industrial Products GmbH

Wuppertal / Germany

Columbus McKinnon Industrial Products GmbH claims proprietary r

ights in the material disclosed hereon. This drawing and/or tec

hnical information is issued in confidence

for engineering information only and may not be reproduced or u

sed to manufacture anything shown or referred to hereon without

direct permission

from Yale to the user. This drawing and/or technical informatio

n is loaned for mutual assistance and is subject to recall by Y

ale at any time.

This drawing and/or technical information is the property of Ya

le.

NOTICE TO PERSONS RECEIVING THIS DRAWING AND/OR TECHNICAL INFOR

MATION

ECN

Rev. Description of change

Date

By

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

04/08/2008

04/08/2008

Velbert

kon3

kon3

Hurricane III 1,0/1

Hand chain hoist 1000/1

Flaschenzug 1000/1 - VG

84700017

kon6

04/14/2010

Standard:

Material No:

Specified Tolerances

ISO 8015

Edges According to

DIN 6784

First Angle Projection

STEP 3:

Block the load chain by inserting a screwdriver or pin

through the load chain just below the hoist frame. Operate the

handwheel in the up direction to remove the slack from the load

chain, closing and locking the brake.

Columbus McKinnon

Industrial Products GmbH

Yale-Allee 30

42329 Wuppertal / Germany

Modeled:

Drawn:

Approved:

Design Authority:

Original project:

Original scale:

1:3

Material:

General Tolerances

ISO 2768-mk

Dimensional Units

mm

Description:

Number:

Sheet

1

1

Format

F

E

D

C

B

A

1

2

3

4

A4

Columbus McKinnon

Industrial Products GmbH

Wuppertal / Germany

Columbus McKinnon Industrial Products GmbH claims proprietary r

ights in the material disclosed hereon. This drawing and/or tec

hnical information is issued in confidence

for engineering information only and may not be reproduced or u

sed to manufacture anything shown or referred to hereon without

direct permission

from Yale to the user. This drawing and/or technical informatio

n is loaned for mutual assistance and is subject to recall by Y

ale at any time.

This drawing and/or technical information is the property of Ya

le.

NOTICE TO PERSONS RECEIVING THIS DRAWING AND/OR TECHNICAL INFOR

MATION

ECN

Rev. Description of change

Date

By

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

04/08/2008

04/08/2008

Velbert

kon3

kon3

Hurricane III 1,0/1

Hand chain hoist 1000/1

Flaschenzug 1000/1 - VG

84700017

kon6

04/14/2010

Standard:

Material No:

Specified Tolerances

ISO 8015

Edges According to

DIN 6784

First Angle Projection

When closing and locking the load brake with the load chain blocked

avoid applying more force than is needed to completely close the

brake. Applying too much force could result in the screwdriver or pin

blocking the load chain to bend or fracture.