Ultra Classic (VT) Series

Page 3

To avoid equipment damage, DO NOT use these

units as a source of heating or cooling during the

construction process. The mechanical components

and filters used in these units will quickly become

clogged with construction dirt and debris which

may cause system damage.

To avoid the release of refrigerant into the

atmosphere, the refrigerant circuit of this unit

must be serviced only by technicians who meet

local, state and federal proficiency requirements.

All refrigerant discharged from this unit must be

recovered WITHOUT EXCEPTION. Technicians

must follow industry accepted guidelines and all

local, state and federal statutes for the recovery

and disposal of refrigerants.

If a compressor is removed from this unit,

system refrigerant circuit oil will remain in the

compressor. To avoid leakage of compressor oil,

the refrigerant lines of the compressor must be

sealed after it is removed.

The installation of geothermal heat pump units and all

associated components, parts and accessories which

make up the installation shall be in accordance with

the regulations of ALL authorities having jurisdiction

and MUST conform to all applicable codes. It is the

responsibility of the Installing Contractor to determine and

comply with ALL applicable codes and regulations.

Pre-Installation

Installation, operation and maintenance instructions

are provided with each unit. Before unit start-up, read

all manuals and become familiar with the unit and its

operation. Thoroughly check the system before operation.

Prepare units for installation as follows:

1. Compare the electrical data on the unit nameplate

with ordering and shipping information to verify the

correct unit has been shipped.

2. Keep the cabinet covered with the shipping carton

until installation is complete and all plastering,

painting, etc., is finished.

3. Verify refrigerant tubing is free of kinks or dents and

that it does not touch other unit components.

4. Inspect all electrical connections. Connections must

be clean and tight at the terminals.

Remove Fan Motor shipping bracket in rear of

Air Handler compartment.

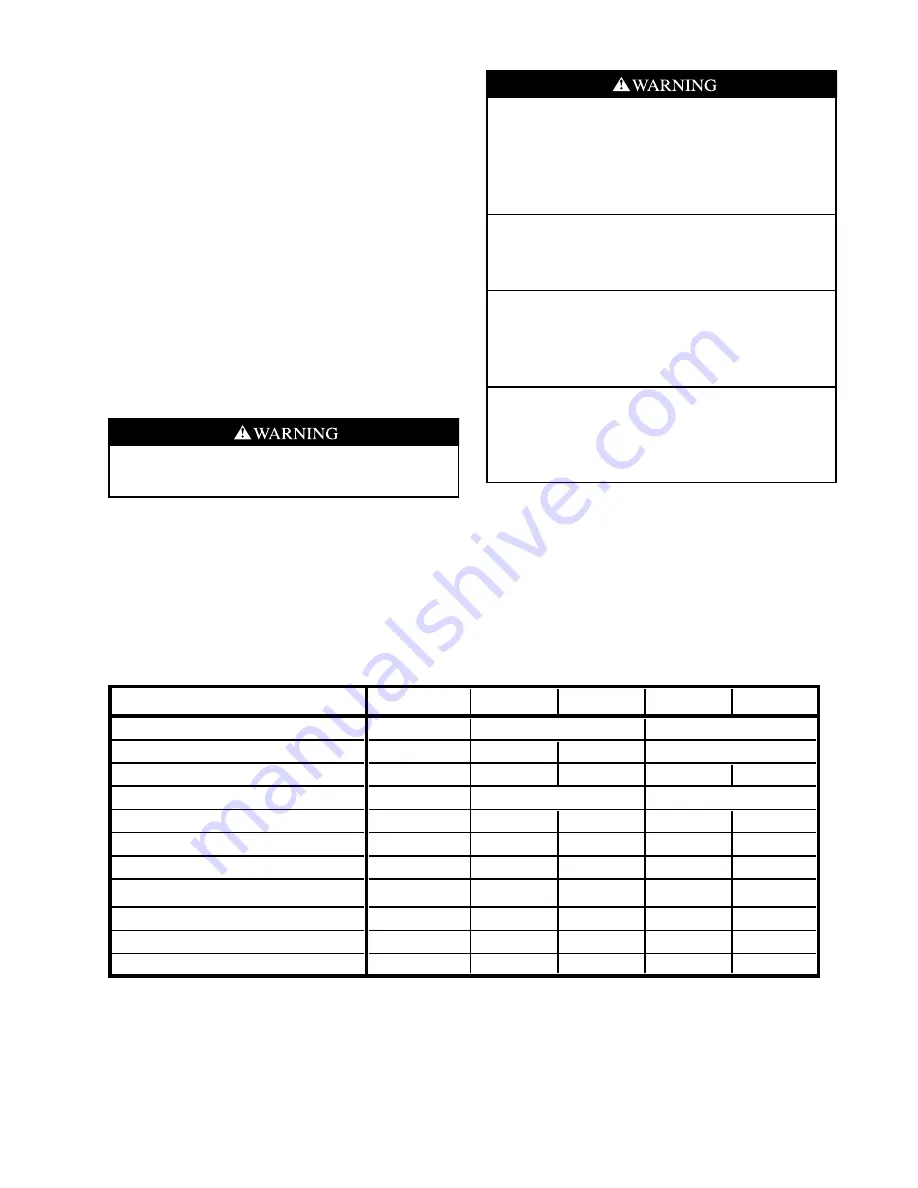

Table 1: Physical Data

VT Physical Data

MODEL

036

042

048

060

072

Fan Wheel (Dia. X Width), in.

9 X 7

Fan Motor & HP

ECM - 1/2

ECM - 1/2

ECM - 1

No. Refrigerant Circuits

2

2

2

2

2

Compressors

2 - Rotary

No. Coaxial Heat Exchangers

2

2

2

2

2

R - 22 Charge (Sys A / Sys B), oz

40 / 40

57 / 59

62 / 62

54 / 54

58 / 58

Water Connection Size (fpt swivel)

1"

1"

1"

1"

1"

Air Coil Length x Height, in.

20 X 24

24 X 24

24 X 32

24 X 36

24 X 36

Filter - 1" ElectroStatic (Std.)

24 x 24

27 x 31

27 x 31

27 x 35

27 x 35

Weight - Operating (lbs.)

225

275

305

385

450

Weight - Packaged (lbs.)

235

285

315

395

460

Rev.: 8/07/04D

All units have txv expansion devices, 20 ga sheet metal,

and 7/8" & 1-1/8" electrical knockouts.

All units have dual 1" Swivel water connections (4 total)

HWG utilizes 1/2" fpt water connections and is available only on circuit A.

All units have 3/4" fpt condensate drain connections.

Revision

Date

Data from Tom North 9/00

10/30/00

Changed filter rack and filter data checked with Enertech

11/13/00

Changes for new comp in 036, 060, and 072 and Electrost Filter & Rack Std 3/30/01

2 - Scroll

11 X 10

11 X 10

ECM - 1

2 - Scroll

Removed Air Coil Data

8/07/04

GENERAL INFORMATION