18

C l i m a t e M a s t e r Wa t e r- S o u rc e H e a t P u m p s

C L I M A T E M A S T E R W A T E R - S O U R C E H E A T P U M P S

Tr a n q u i l i t y

®

3 0 ( T T ) S e r i e s

R e v. : 0 7 / 1 8 / 1 3

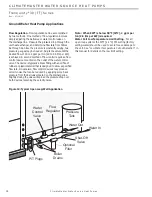

Figure 14: Typical Open Loop/Well Application

3UHVVXUH

7DQN

6KXW2II

9DOYH

%RLOHU

'UDLQV

)ORZ

5HJXODWRU

:DWHU,Q

:DWHU2XW

:DWHU

&RQWURO

9DOYH

2SWLRQDO

)LOWHU

373OXJV

Ground-Water Heat Pump Applications

Flow Regulation

- Flow regulation can be accomplished

by two methods. One method of fl ow regulation involves

simply adjusting the ball valve or water control valve on

the discharge line. Measure the pressure drop through the

unit heat exchanger, and determine fl ow rate from Tables

8a through 8e. Since the pressure is constantly varying, two

pressure gauges may be needed. Adjust the valve until the

desired fl ow of 1.5 to 2 gpm per ton [2.0 to 2.6 l/m per kW]

is achieved. A second method of fl ow control requires a fl ow

control device mounted on the outlet of the water control

valve. The device is typically a brass fi tting with an orifi ce of

rubber or plastic material that is designed to allow a specifi ed

fl ow rate. On occasion, fl ow control devices may produce

velocity noise that can be reduced by applying some back

pressure from the ball valve located on the discharge line.

Slightly closing the valve will spread the pressure drop over

both devices, lessening the velocity noise.

Note: When EWT is below 50°F [10°C], 2 gpm per

ton (2.6 l/m per kW) is required.

Water Coil Low Temperature Limit Setting

- For all

open loop systems the 30°F [-1.1°C] FP1 setting (factory

setting-water) should be used to avoid freeze damage to

the unit. See “Low Water Temperature Cutout Selection” in

this manual for details on the low limit setting.