P1789E 06/04

9

250PTHFC226

5. What to Do, If...

... the torque is too low?

- Is the exhaust air throttle adjusted correctly?

- Is the flow pressure too low?

- Is the reverse button not in one of its end positions?

- Is the inlet screen choked?

- Is the muffler choked?

- Is the oil volume in the pulse unit sufficient?

6. Repair Instructions

6.1 Disassembling the Motor

-

Clamp tool at the pistol grip <1> in a vice with plastic jaws.

Caution!

Caution!

Do not damage the rubber coat of the grip.

-

Loosen housing <92> counterclockwise using a strap wrench.

-

Pull off housing and pulse unit.

-

Remove countersunk screw <11> and reverse button <10>.

-

Remove circlip <46>.

-

Knock pistol housing against soft base and remove motor parts.

-

When the push-rod <33> is actuated, the shut-off unit can be

pulled off manually. If required, force rotor <41> from deep groove

ball bearing <36>.

6.2 Diassembling the Switch-On Valve

-

Lift push-button <21> off with size 2 screw driver.

-

Unscrew valve plug <19> with pin wrench

<F>

(pin spacing 11

mm, diameter 2 mm) counterclockwise.

-

Remove unscrewed valve unit downward.

6.3 Assembling the Motor

Caution!

Caution!

To prevent damaging the O-rings, apply grease to them

before assembly (Order No. 914392).

During assembly, be sure to observe the sequence

shown in the spare parts drawing.

-

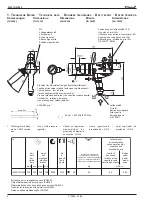

Force rotor cover <37> with deep groove ball bearing <36> onto

rotor <41> using assembly device

<E>

(8. Assembly Notes,

fig. 1+2).

-

Slide on air distributor <35>.

-

Install seal ring <29> in shut-off piston <30>.

-

Slide push-rod <33> into rotor <41> (assembly aid) and put onto

assembly device

<G>

(fig. 4).

-

Install shut-off bolt <32> and balls <42>.

-

Lock compression spring <31> in bore.

-

Install pre-assembled shut-off piston <30> onto rotor.

-

Lift complete rotor, without push-rod <33> from the assembly

device. The shut-off piston is thereby locked to the rotor.

-

Install governor <28> - <22> (7. Spare Parts Drawing)

-

Insert O-ring <34> in pistol grip housing.

-

Slide the pre-assembled parts into the pistol grip housing. The

groove in the circumference of the air distributor <35> should be

aligned to the center of the switch-over groove, to allow to secure

the assembly with the pin.

-

Fasten reverse button <10> with countersunk screw <11>.

-

Slide rotor cylinder <38> with cylinder pins <39> and <40> into the

pistol grip housing.

-

To simplify assembly grease the pins <39> and <40>.

-

Push the blades <43> into the slots in the rotor <41>.

-

Install ball bearing <45> in rotor cover <44> and then assemble

both with the pistol grip housing.

-

Fit circlip <46>.

Caution!

Caution!

Do not cover the bore in the rotor cover <44>.

-

Slide push-rod <33> back into the rotor.

The motor module must be switched on only when it has

been completely assembled with pulse unit <55> and

housing <92>.

Caution!

Caution!

When installing the strainer <6>, be sure the circlip <7>

lies flat on the strainer.

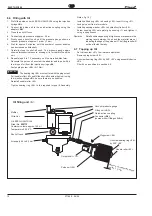

6.4 Disassembling the Pulse Unit

This is allowed only if you can guarantee filling with the oil

filler unit

<A>

. The pulse unit must have cooled down to

room temperature.

-

Clamp hydraulic cyclinder <86> in vice with flat jaws using

assembly device

<C2>

(8. Assembly Notes, fig. 5)

To prevent hazard to your health and the environment, be

sure to observe the locally applicable rules for safety and

prevention of accidents.

-

Loosen bearing ring <56> with the assembly device

<C1>

.

-

Loosen plug screw <88>.

-

Remove the pulse unit from the assembly device

<C2>

.

-

Remove plug screw <88> and bearing ring <56> while holding the

unit above an oil pan.

-

Separate hydraulic cylinder <86> and hydraulic rotor <73> by

slightly pressing on the latter.

The hydraulic blades are spring-loaded!

-

Remove the parts installed in the hydraulic rotor by removing the

two circlips <66> and <83>.

-

Clean all parts.

Caution!

Caution!

Generally use only original CLECO spare parts. If spare

parts not manufactured by us are installed, the

manufacturer of the nutsetter is entitled to deny any

warranty claims.

6.5 Assembling the Pulse Unit

Caution!

Caution!

To prevent damaging the O-rings, apply grease to them

before assembly (Order No. 914392).

-

Assemble the pulse unit by reversing the assembly sequence

outlined for disassembly (7. Spare Parts Drawing).

-

Be sure to observe the right installation position for the two control

blades <71> and <72> (8. Assembly Notes, fig. 6 - 15).

-

To simplify assembly, use the assembly device

<D>

.

-

Using assembly device

<C>

screw bearing ring <56> into the

hydraulic cylinder until stop.

-

Loosen bearing ring by 360° +90° and fill unit with oil as outlined

in section 6.6.