1992e_Ersatzteile_en.fm, 12.06.2014

P1992BA/EN 2014-06

33

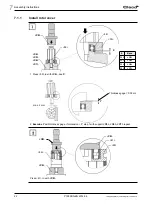

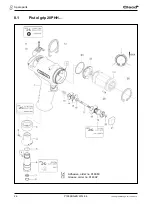

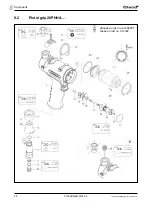

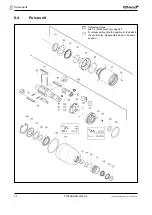

Spare parts

8

1)Order no.

2)Quantity

3) Part of hydraulic service kit K2, order no. 936210

4)Dimensions

*

Order no.

<84>

<93>

<115>

<116>

<117>

<118>

<119>

<120>

20PHH753

20PHHA753

936041

935658

–

–

–

–

–

–

20PHH75Q

20PHHA75Q

936042

935685

931789

917794

935477

935406

931793

931789

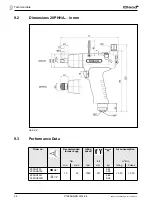

Summary of Contents for 20PHH

Page 12: ...12 P1992BA EN 2014 06 1994b_1_5_en bedingt fm 12 06 2014 Before initial operation 4 ...

Page 18: ...18 P1992BA EN 2014 06 1994c_Wartung_en bedingt fm 12 06 2014 Maintenance 5 Empty side ...

Page 24: ...24 P1992BA EN 2014 06 1994d_Reparatur_en bedingt fm 12 06 2014 Assembly instructions 7 ...