Copyright © 2016 Clayton Associates, Inc. • 1650 Oak St. • Lakewood, NJ 08701

800-248-8650 • www.VacuumSanding.com

2

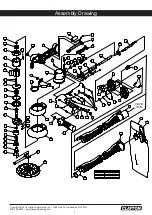

Assembly Drawing

1

2

3

4

5

7

6

8

9

10

11

13

17

18

19

20

21

22

14

15

16

23

24

25

26

27

28

29

32

31

33

34

36

35

37

38

39

40

41

42

43

44

45

46

47

48

49

25

50

53

52

54

55

56

52

53

57

58

59

61

60

62

63

52

51

64

TO VACUUM

SYSTEM FOR

CENTRAL

VACUUM

65

66

67

68

30

12

69

70

REVISION RECORD

R

DESCRIPTION / DATE

A

-RELEASE FOR PRODUCTION

RAG 11/12/08 PWH 11/12/08

B

-ITEM 30 XPA2398 WAS XPA2159

-ITEM 30 XPA2400 WAS XPA2160

-XPA2158 WAS REMOVED

RAG 03/17/10 MDR 03/18/10

C

-ITEMS 69 & 70 WERE NOT ON

MCC 03/08/12 FNK 03/08/12

IT

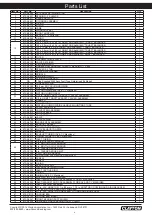

P/N

DESCRIPTION

QTY

1

XPA0040 EXTERNAL RETAINING RING

1

2

XPA0021 10 X 26 X 8 BEARING - 2 SHIELDS

1

3

XPB0017 REAR ENDPLATE

1

4

XPA0441 50.0 X 36.0 mm CYLINDER ASSEMBLY

1

5

XPA0042 5 mm x 2.0 mm O-RING

1

6

XPB0118 Ø 50.0 mm x 36 mm MOTOR MACHINED ROTOR

1

7

XPA0445 VANE FOR Ø 50.0 mm x 36.0 mm MOTOR

5

8

XPA0041 3 mm x 13 mm WOODRUFF KEY

2

9

XPB0016 FRONT ENDPLATE

1

10

XPA0019 12 X 28 X 8 BEARING - 2 SHIELDS

1

11

XPA0045 39.4 mm x 3.1 mm O-RING

1

12

XPA0001 LOCK RING

1

13

XPB0206 TwoHAND 125 x 2.5 mm (5 x 3/32 in.) ORBIT ROS AirSHIELD™ SHAFT

BALANCER

1

13

XPB0207 TwoHAND 125 x 5.0 mm (5 x 3/16 in.) ORBIT ROS AirSHIELD™ SHAFT

BALANCER

1

13

XPB0189 TwoHAND 125 x 10 mm (5 x 3/8 in.) ORBIT ROS AirSHIELD™ SHAFT

BALANCER

1

13

XPB0205 TwoHAND 150 x 2.5 mm (6 x 3/32 in.) ORBIT ROS AirSHIELD™ SHAFT

BALANCER

1

13

XPB0187 TwoHAND 150 x 5.0 mm (6 x 3/16 in.) ORBIT ROS AirSHIELD™ SHAFT

BALANCER

1

13

XPB0188 TwoHAND 150 X 10 mm (6 x 3/8 in.) ORBIT ROS AirSHIELD™ SHAFT

BALANCER

1

14

XPA0122 FILTER

1

15

XPA0121 DUCKBILL CHECK VALVE

1

16

XPA0120 VALVE RETAINER

1

17

XPA0090 11.9 mm (15/32 in.) RETAINING RING

1

18

XPA0751 12 x 32 x 15.9 DOUBLE ROW ANGULAR CONTACT BEARING - 1 SEAL

1

19

XPA1767 SPACER 12.1 ID x 22.0 OD x 0.2 THK

1

20

XPA1024 BELLEVILLE WASHER

1

21

XPB0208 SPINDLE

1

22

XPA1025 RETAINING RING

1

23

XPA0022 24 mm PAD WRENCH

1

24

NA

1 Pad Supplied With Each Tool (Type Determined By Model)

1

25

XPA2058 M8 THREADED PLUG - PMS 123C YELLOW

2

26

XPB0395 36.0 mm RH VACUUM CLAYTON HOUSING

1

27

XPA0032 MUFFLER INSERT (for 10,000 RPM Machines)

1

28

XPA1218 TOP HOUSING SEAL (NV & CV Machines)

1

29

XPB0290 36.0 mm MOTOR HOUSING SEAL

1

30

XPA2398 CLAYTON ROS 12,000 RPM 3/16 in. ORBIT THROTTLE SAFETY LEVER

ASSEMBLY - TwoHAND

1

30

XPA2400 CLAYTON ROS 12,000 RPM 3/8 in. ORBIT THROTTLE SAFETY LEVER

ASSEMBLY - TwoHAND

1

31

XPA2062 HANGER - PMS 123C YELLOW

1

32

XPA1865 SPACER RING

2

33

XPB0356 36.0 mm DIE-CAST MACHINE MOTOR HOUSING W/SIDE HANDLE

MOUNTING STUDS

1

34

XPA0004 CYLINDER SPRING PIN

1

35

XPA0655 VALVE STEM ASSEMBLY

1

36

XPA0015 VALVE SLEEVE

1

37

XPA0009 VALVE SEAT

1

38

XPA0007 VALVE

1

39

XPA0014 VALVE SPRING

1

40

XPA0730 AIRLINE SEAL ASSEMBLY

1

41

XPA0500 EXHAUST GASKET

1

42

XPB0181 36.0 mm MOTOR SGV EXHAUST NOZZLE

1

43

XPB0182 NV/CV EXHAUST NOZZLE

1

44

XPA0664 M4 X 8 HEX SOCKET BUTTON HEAD CAP SCREW

3

45

XPA0517 EXHAUST TUBING (NV & CV Machines)

1

46

XPA0516 TUBING CLAMP (NV & CV Machines)

1

47

XPA0511 INLET TUBING

1

48

XPC0153 TwoHAND™ 5/6 in. BUFFER/NV SHROUD

1

49

XPA2060 TwoHAND™ 5 in. MULTI-HOLE/LP SHROUD - PMS 123C YELLOW

1

49

XPA2061 TwoHAND™ 6 in. MULTI-HOLE/LP SHROUD - PMS 123C YELLOW

1

49

XPC0147 5 in. TAPERED EDGE SKIRT

1

49

XPC0146 6 in. TAPERED EDGE SKIRT

1

50

XPA1998 CLAYTON SIDE HANDLE

1

51

XPB0472 36.0 mm LH PMS 123 YELLOW HOUSING WITH BLACK OVERMOLD

1

52

XPA1398 SCREW, BUTTON HEAD TORX M4.0 X 15 mm BLACK

5

53

XPA1430 SCREW, BUTTON HEAD TORX M4.0 X 30 mm BLACK

7

54

XPA0043 9 mm x 1.5 mm O-RING

1

55

XPA2059 TwoHAND SPEED CONTROL - PMS 123C YELLOW

1

56

XPA0039 INTERNAL RETAINING RING

1

57

XPA0510 2 HAND INLET CAPTIVE RING

1

58

XPA0509 7.6 mm x 1.78 mm 0-RING

1

59

XPA0628 O-RING (NV & CV Machines)

1

60

XPA0776 MUFFLER (NV & CV Machines)

2

61

XPA0731 INLET/EXHAUST END CAP ASSEMBLY FOR NV MACHINES

1

62

XPA2066 INLET/EXHAUST END CAP ASSEMBLY FOR SGV AND CV MACHINES - PMS

123 YELLOW

1

63

XPA0013 1/4-18 NPT INLET BUSHING ASSEMBLY

1

64

XPA0392 Ø1 in. VAC HOSE TO Ø1 in./28 mm x 1 1/2 in. ADAPTOR COUPLING AND

AIRLINE ASSEM

1

65

XPA0623 1 in. (28 mm) HOSE SEAL-TwoHAND™ (SGV Machines)

1

66

XPA0412 Ø 1 in. VAC HOSE TO DOUBLE BAG FITTING AND AIRLINE ASSY

1

67

XPC0110 VACUUM BAG

1

68

XPC0109 VACUUM BAG INSERT

1

69

XPA2541 FRONT BEARING DUST SHIELD

1

70

XPA2540 TwoHAND SPINDLE BEARING DUST SHIELD

1

ITEM NO.

TORQUE SETTINGS in.-lbs (N-m)

12

55 - 65 (6.2 - 7.3)

43

21 - 30 (2.4 - 3.4)

52

27 - 30 (3.0 - 3.4)

53

29 - 33 (3.3 - 3.7)

63

60 - 72 (6.8 - 8.1)

XPD0066

P/N

TITLE

DRWN BY / DATE

MATERIAL

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE

PROPERTY OF X'POLE PRECISION TOOLS INC. ANY REPRO-

DUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF X'POLE PRECISION TOOLS INC. IS PROHIBITED.

CKD BY / DATE

ENG APP / DATE

STD TOL

.X +/-

.XX +/-

.XXX +/-

XX/XX +/-

ANGLES +/-

0.1

0.05

NA

NA

0.5°

X'POLE

PRECISION

TOOLS INC.

RAG

11/12/08

11/12/08

PWH

SEE BOM

CLAYTON 5 & 6 in. (125 & 150 mm) 12,000

RPM TwoHAND™ ROS