6

E

N

G

LI

S

H

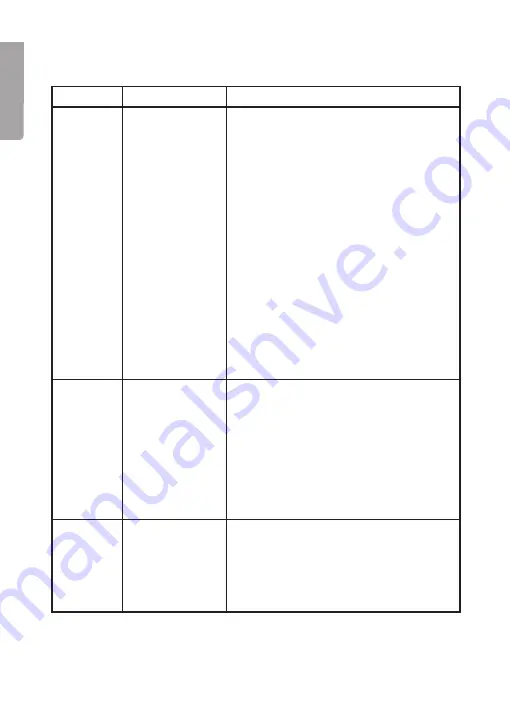

Troubleshooting

Problem

Possible cause

Remedy

The

hammer

is slow or

does not

operate.

1. Debris inside.

. Not lubricated.

3. Low air

pressure.

4. Leak in air

hose.

5. Loss of air

pressure.

6. Regulator is

set too low.

1. Rinse the inside of the hammer with

50/50 mix of SAE 10 oil and kerosene.

Lubricate the hammer after cleaning.

. Lubricate as directed.

3. Adjust the compressor’s pressure

regulator.

4. Fix the leak. Tighten the hose clamps.

5. Check to that the hose’s inner

diameter is adequate. Long hoses or

tools which demand a large amount

of compressed air require a hose

with a 1/˝ inner diameter or more,

depending on the total length.

6. Adjust the regulator until the hammer

reaches its maximum number of blows

per minute.

The

hammer

releases

moisture.

1. Water in the

tank.

. Water in the

hose.

1. Empty tank. See the compressor’s

manual. Lubricate the hammer and run

until no moisture is released. Re-oil the

hammer and run for 1 - sec.

. Install a water separator. Make

sure the water separator is installed

as close to the tool as possible.

Immediately lubricate every time water

gets into the tool.

The air

hammer

does not

move either

forwards or

backwards.

1. Piston has

jammed in

cylinder.

1. Fill with oil in order to loosen them.

Summary of Contents for 30-6215

Page 27: ......