6

Parts & Service: 020 8988 7400 / E-mail: [email protected] or [email protected]

AIR SUPPLY

The air supply pressure to the container should be clean and not be greater

than 80 psi. Higher pressure or contaminated air will shorten the spray gun life

because of faster wear, and could become a safety hazard.

Water in the airline will also cause damage and may contaminate the paint

being used. Ensure the air supply is properly filtered.

The recommended procedure to connect the container to an air supply is

described below. A filter/regulator should always be incorporated in the air

supply line.

The air inlet used for connecting air supply has a standard ¼” BSP thread.

Airline pressure, or supply hose inside diameter, should be increased to

compensate for unusually long air hoses (over 10 m). The minimum hose

diameter should be 6mm (¼”) ID and fittings should have the same internal

dimensions.

OPERATION

This CPP2B paint container is designed primarily for spraying oil and solvent

based paint. Clarke International provides a range of spray guns which may

be used with this container. Please see examples on page 11.

1. Mix the paint to the correct viscosity for spraying according to the

manufacturer’s instructions and strain it into the paint canister through a

fine mesh filter. When mixing the paint, make sure that you have enough

thinners left to clean the spray gun after use.

2. Unscrew the lid and fill the paint

container with paint. Replace the

lid and tighten securely.

3. Connect the air supply hose to

the air inlet, (using a suitable in-

line connector if required).

4. Connect the (orange) air hose

from the spray gun, to the air

outlet.

WARNING: ALWAYS CHECK TO ENSURE THE CONTAINER IS NOT UNDER

PRESSURE BEFORE USE, BY CHECKING THE PRESSURE GAUGE AND

OPENING THE AIR OUTLET VALVE.

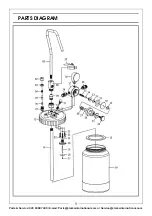

Summary of Contents for CPP2B

Page 12: ......